8

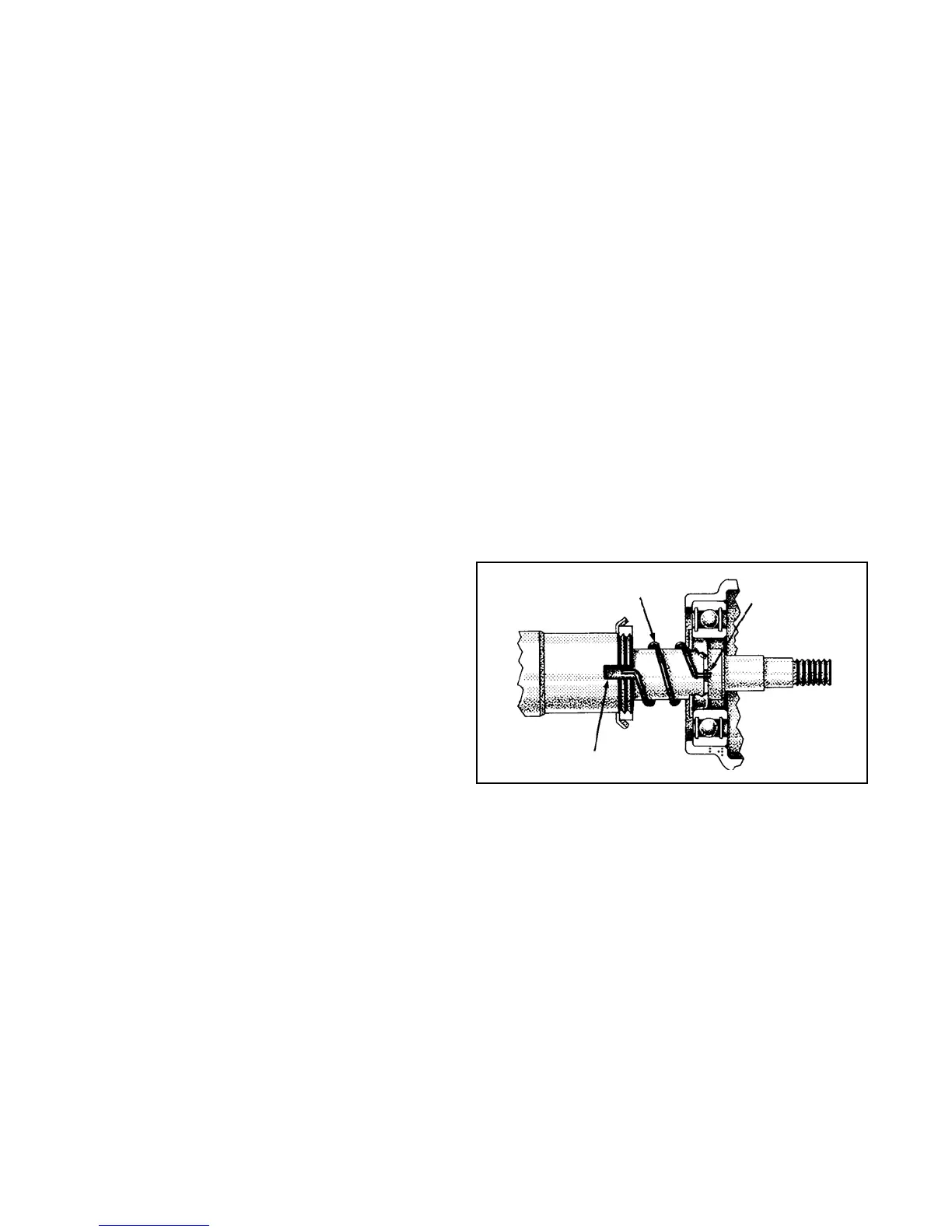

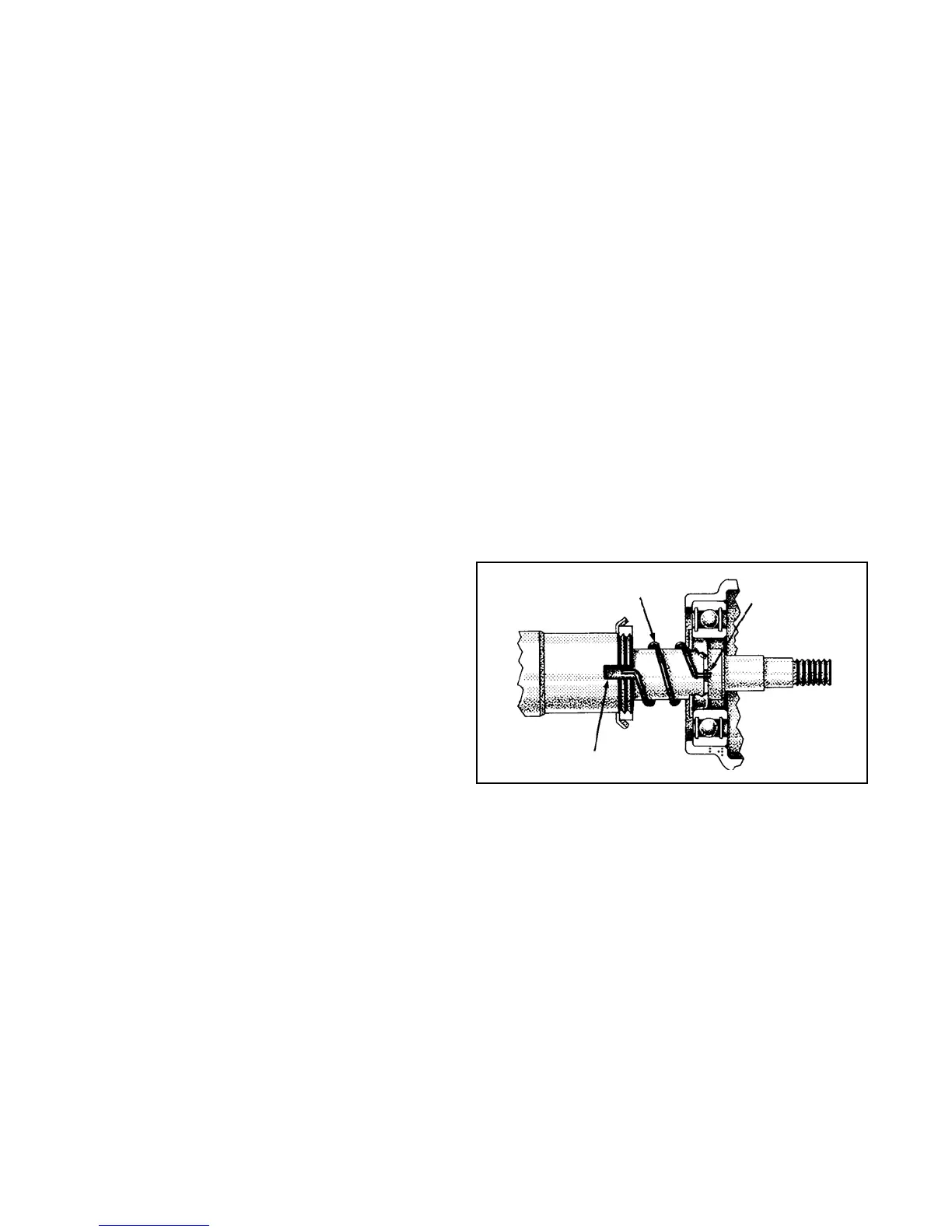

FIGURE 12

The spacer (12) should be tight against both bearing

inner races, yet be able to be moved by a finger load.

3. Turn the fan plate over and install snap ring (14) with the

flat side towards the bearing, making certain the snap

ring is fully seated in its groove.

ASSEMBLY OF FAN PLATE WITH 2.560 PILOT

DIAMETER

1. Support the fan plate on the fan mounting surface (nose

down). Using a pressing tool that contacts the outer

bearing race only, press ball bearing (13) into the fan

plate using a force no greater than 1100 lbs. Until it

contacts the fan plate shoulder. Install the bearing

spacer(12) (as illustrated in Figure 1) concentric with

the inner race of the ball bearing previously installed.

2. Continue to support the fan plate (nose down) and press

bearing (11) using a pressing tool that contacts the outer

race of the bearing only. Carefully press the bearing

with a force no greater than 1100 lbs. until the inner

bearing race contacts spacer (12). Do not continue

pressing the bearing once the inner race has touched

the spacer; severe damage to the bearings may result.

As a check after assembly, the bearing spacer should

be tight against each bearing race yet able to be moved

by a finger load.

3. Turn the fan plate over and install snap ring (14) with

the flat side towards the bearing, making certain the

snap ring is fully seated in its groove.

FINAL ASSEMBLY

1. Support the bracket, shaft, and pulley assembly with

the shaft pointing up.

2. Install spring pack (9) onto the pulley assembly and

retain with the two 1/4"x20 Phillips screws. Torque to

50-75 inch pounds.

3. Install the anti-rotational spring(17) making sure one

end of the spring is engaged in the notch of the shaft.

(See Figure 12)

4. Apply a thin film of silicone lubricant BW-655M to the

four o-rings(6). Position the o-rings into the grooves

located in the drive pin holes of the pressure plate(7).

Apply the same lubricant to the drive pins on the pulley.

5. Install the pressure plate(7) onto the pulley assembly

making sure the end of the antirotational spring(17) is

engaged in the notch of the spring collar on the I.D. of

the pressure plate. Holes in the pressure plate must

slide over the drive pins.

6. Lubricate the I.D. of the piston housing(15) and the

three o-rings (3,4, & 5) with lubricant used in Step 4.

Install o-rings (4&5) onto the piston and o-ring (3) onto

the shaft.

7. Install piston(16) into the piston housing(15) and install

unit onto the shaft.

8. Install fan plate assembly onto the shaft and retain with

the locknut(10). NOTE: On unit with 2.560 diameter

hub, washer(11) to be installed before the locknut. Torque

to 90 to 100 ft.lbs.

9. Install cotter pin(2) and bend to hold in place. Replace

cap(1).

INSTALLATION

1. Attach fan clutch unit to vehicle by installing cap nuts

and lockwashers through mounting bracket holes into

mating holes in engine bracket.

2. Reconnect air line to unit.

3. Adjust fan belts per vehicle manufacturer’s

recommendation.

4. Replace fan on pressure plate with six cap screws and

lockwashers. Torque to 300-360 inch pounds. (Be sure

to install any spacers that were removed during

disassembly.)

5. Perform service checks as previously outlined.

TEST

1. With no air pressure applied, the torque required to rotate

the clutch must not exceed 150 in. oz.

2. With 70-75 psi applied, the fan plate must separate from

the pulley and rotate freely.

3. Perform the leakage checks outlined in the manual.

RETROFIT INSTALLATION

INFORMATION

To determine which fan clutch piece number should be

purchased when retrofitting existing equipment, consult the

nearest authorized Bendix distributor for assistance.

Complete installation instructions and piping diagrams are

packed with each FD-3

™

TorqueMaster fan clutch.

It is recommended that only cooling fans approved by the

vehicle or fan manufacturer be installed on the

FD-3

™

TorqueMaster.

Maximum weight of fan blade assembly is 30 lbs.

Maximum R.P.M. of 28 inch fan is 2700.

Maximum R.P.M. of 34 inch fan is 2100.

Maximum thickness of spacers between fan and hub plate

is 1-1/2".

ANTI-ROTATIONAL

SPRING

ONE END OF SPRING

INSTALLED IN NOTCH

IN SPRING COLLAR

ONE END OF SPRING INSTALLED

IN NOTCH OF THE SHAFT

BW1452 © 2004 Bendix Commercial Vehicle Systems LLC All rights reserved. 4/2004 Printed in U.S.A.

Loading...

Loading...