10

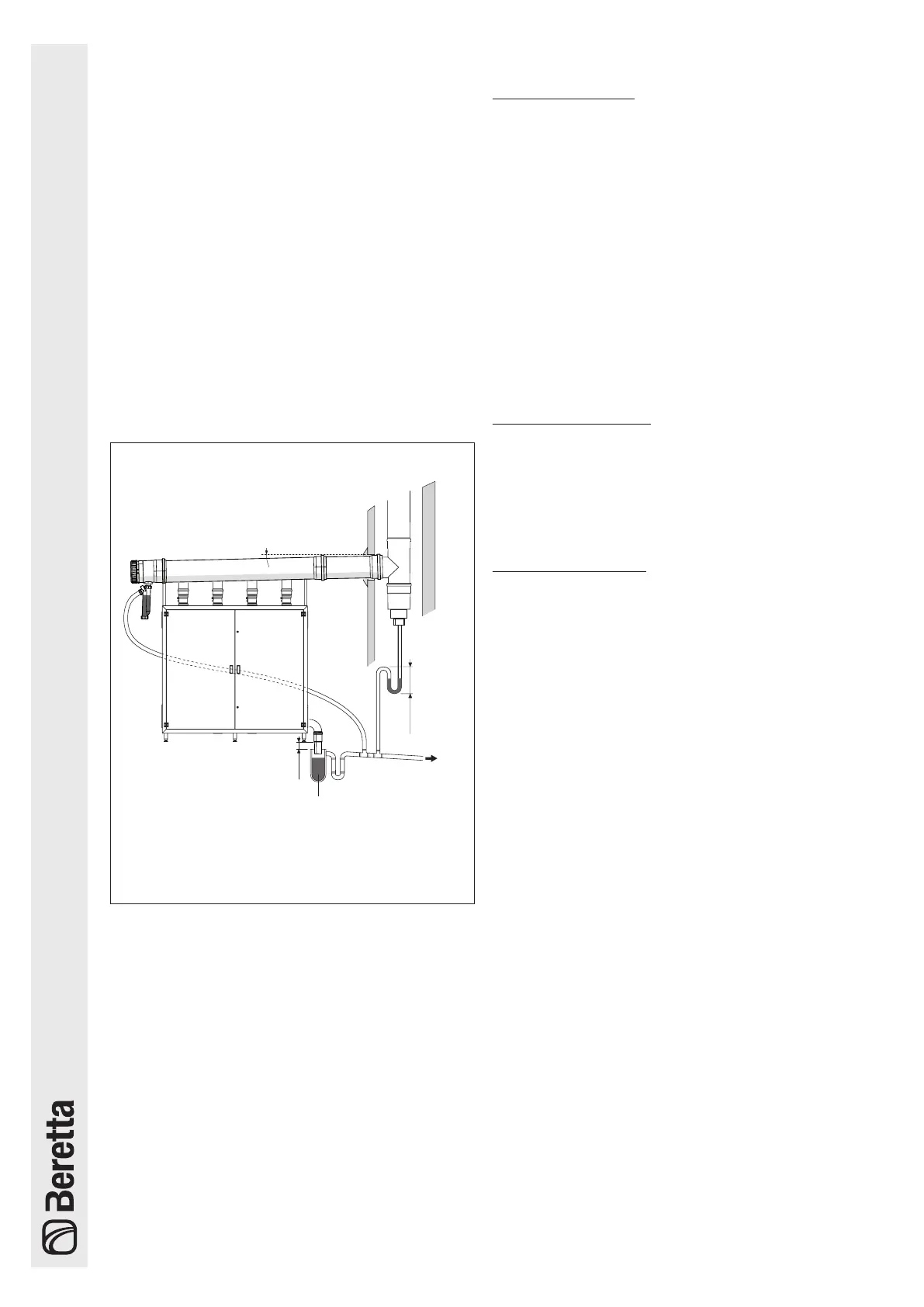

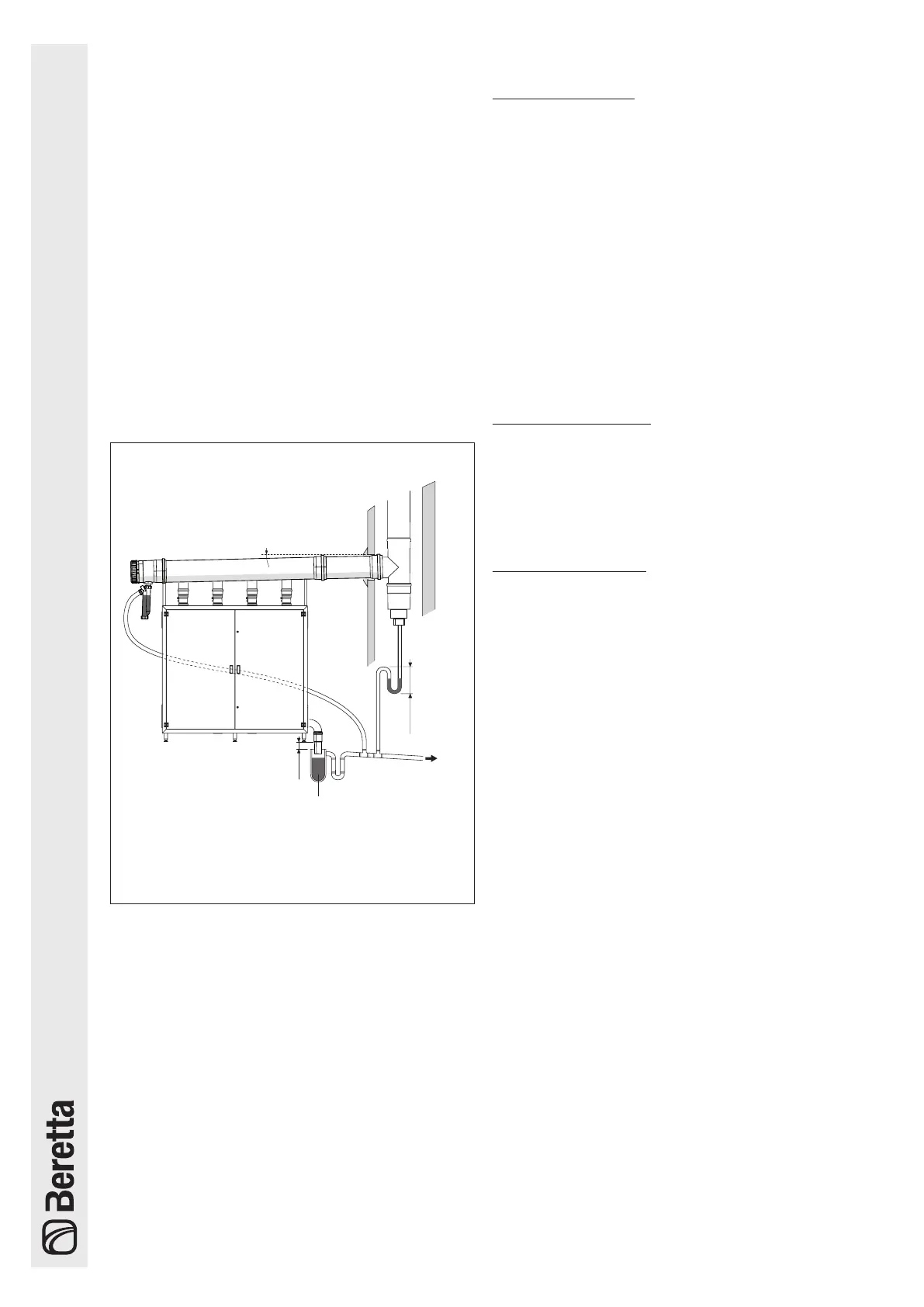

4.6 Condensate outlet

The condensate water produced by

Power Plus Box P INT-

EXT

a normal running conditions is evacuated into a spe-

cial manifold.

Drainage must be done at atmospheric pressure, i.e. by

dripping into a connected drain-trap, as follows:

- install a drip at the condensate drainage manifold;

- connect the drip to the sewerage mains by a drain-

trap;

- be ready to use a neutralizer where required (see pro-

ject cig E.01.08.929.0; ATV A 115).

There is generally no need to take any special precautions

for draining condensate.

We advise using plastic (PP) piping for building the con-

densate drainage.

a

DO NOT for any reason use pipes in copper or in any

other material not specifically used for this particular

scope, as the condensing action could cause rapid

degradation.

(*)

(*)

i > 3%

i

i ≥ 3°

Condensate collector

(*) Fill the siphons with water.

(at atmospheric pressure)

Civil drain

minimum

distance

300 mm

minimum

distance

10 mm

Fig. 7

Furthermore, should the vertical part of the flue exhaust

duct have to be prolonged by more than 4 metres the con-

densate drain-trap will have to be placed at the foot of the

piping. The working height of the drain-trap must be at

least 30 cm. The drain-trap outlet must then be connected

up to the sewerage mains.

b

The condensate drain must be connected to the sew-

erage mains in such way as to prevent it from being

frozen under any circumstances.

b

Always install a condensate drain in the exhaust flue

duct at no more than 1 m from the boiler

4.7 Water circuit

WORKING PRESSURE

The maximum working pressure of the boiler is 6 bar (600

kPa) whilst the minimum is 0.5 bar (50 kPa).

b

It is compulsory to install devices along the topping

up/supply line as well as the water circulation system

to protect the installation from pressures exceeding

550 kPa, in conformity to prescriptions given in the

EN 60335-2-102.

b

Do not expose the exchanger to cyclic changes in

pressure as fatigue stress does a lot of harm to the

system components. Should the water system sud-

denly start generating changes in pressure it is com-

pulsory to use the protection devices to make the

boiler work at a regular pressure.

b

Installation pressure control must be done under cold

conditions.

FILLING UP THE BOILER

The boiler must be filled up by connecting the water from to

the mains to any part of the installation.

b

It is compulsory to use a standard filling device

(EN61770 type) for coupling up to the mains specifi-

cally preventing the back-flow of liquid from installa-

tion to water mains.

EMPTYING THE BOILER

Emptying of the system is made by acting on the discharge

valves of each unit and in some points of the hydraulic sys-

tem specific for this purpose.

For more information on the characteristics of hydraulic

system see Chapter 5 in which different types of plant are

shown.

4.8 Exhaust ue

The chimney should be as straight as possible, sealed and

isolated. Should not have occlusions or narrowing.

b

The overall potential of thermal groups

Power Plus

Box P INT-EXT

Series is more than 35 kW, so they can

be installed only in rooms that have venting opening

to the outside according to actual law (italian D.M.

12.04.1996).

b

The

Power Plus Box P INT-EXT

series generators must

be connected to a exhaust pipe system in flame re-

tardant polypropylene (PP) or suitable materials ac-

cording to UNI EN 677 and associated standards.

a

DO NOT for any reason use piping not specifically

designed for this specific scope as the condensing

action could cause rapid degradation.

b

Where collectors are used to evacuate the smoke, the

presence of non-return valves within each unit stops

the products of combustion of the active units enter-

ing the boiler room by means of the closed unit intake

ducts.

a

In the event of installation with air intake from the

premises (both in the heating unit and externally)

avoid obstructing the passage of air under the metal

cupboard.

Loading...

Loading...