ELECTRIC C301 - DIAGNOSTICS & TROUBLESHOOTING - GB

5

ELECTRIC C301 - DIAGNOSTICS & TROUBLESHOOTING

The machine controller detects a wide variety of faults or errors.

Diagnosc informaon can be obtained on the 3100R fuel gauge display where an error code in the format ''Err ##''.

The troubleshoong chart below describes the Error code faults and their possible causes.

Whenever a fault is encountered the rst acon should be to turn o the ignion and push in the E stop buon. Then pull out the E stop buon and turn the ignion back

on to see if the fault clears. This is the RESET procedure:.

If the Error code does not clear aer the machine RESET, turn o the ignion switch and remove the 35-pin connector. Check the connector for correcon or damage,

clean it if necessary, and reinsert it.

If the Error is sll seen then the wiring and connecons on the machine should be checked for breakages or loose connecons.

The table below should be used as a reference once the above checks have been carried out.

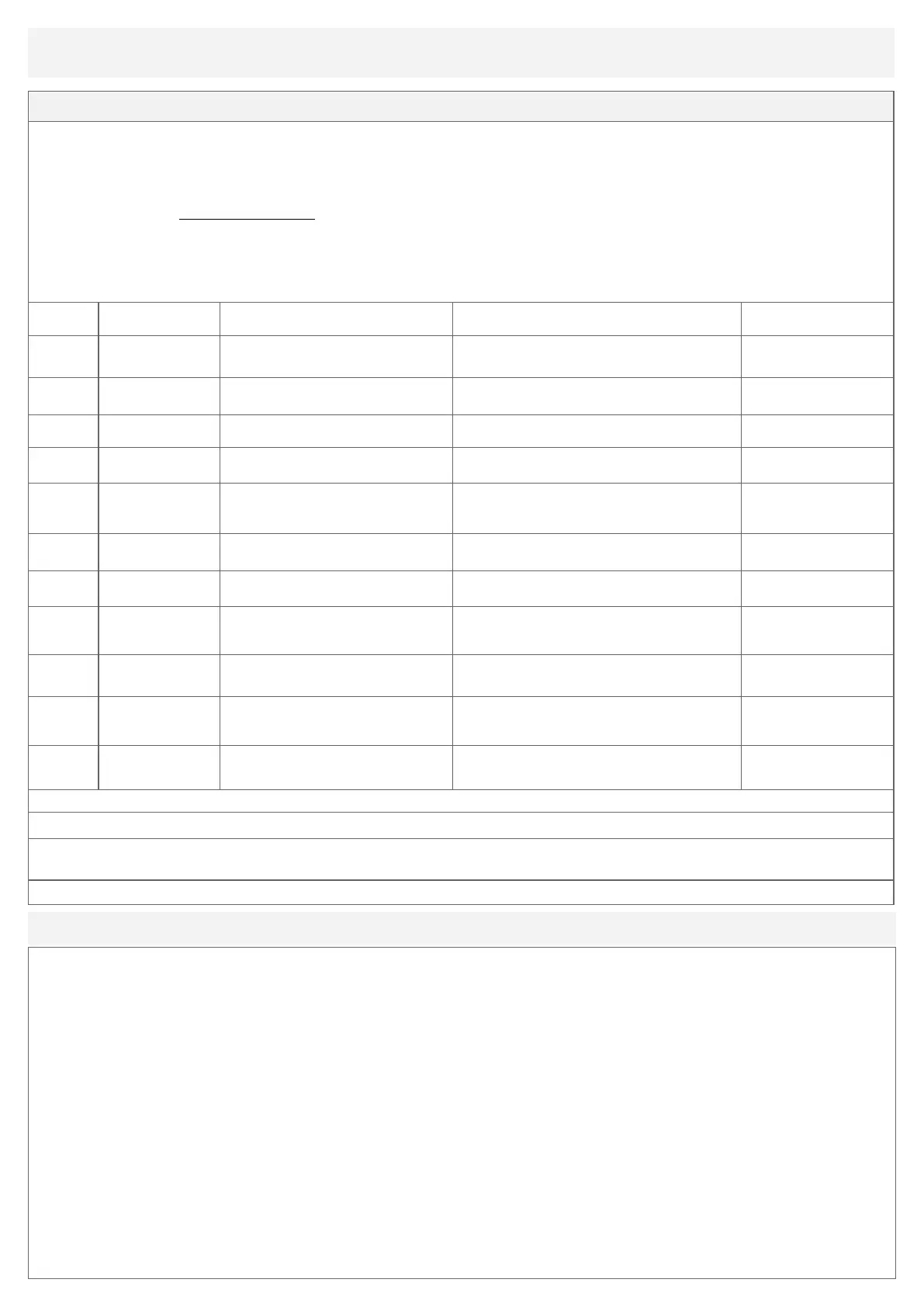

Error code Descripon of Error

Possible Cause /

Reason for Error

Check points

Technical Bullen

(see website)

1

HW

Fail-safe

Motor fault voltage (hardware failure)

1. Motor voltage does not correspond to throle

request.

2. Short in motor or In motor wiring.

10

Main brake driver over

current

Short circuit or overloaded controller driver, Early

controllers were re-programmed

15

Main

Current dropped

Main contractor failed open. 1. Clean the contactor switch TB10001

17

Main

Contactor Welded

Main contractor on fault 1. Main contactor failed closed, replace contactor.

33

Supervisor DIR Check

Fault

If fault is on an external signal, check that

signal rst. If no problem with the external

signal, likely indicates an internal controller

fault.

Early controllers were re-programmed

34 External Supply Fault Under voltage

1. Check control wiring circuit, potenometer wiring in

parcular.

TB10010

36

EM-Brake Driver

Open Drain

Hold voltage is set at 90%

1. Check bullet connectors to brake, check connuity or

2. The motor brake has failed.

54 Pre-charged Failed Pre-charge fault

1. Low baery voltage - 25V (11/12V) is good

condion, 22V (9/10V) or lower is bad baeries

condion.

2. Short circuit on tracon motor outputs.

TB10008

80

HPD

Sequencing

HPD fault present > 10 seconds

1. Misadjusted throle

2. Broken throle potenometer or throle

mechanism.

TB10004

92 Motor Open Tracon motor not connected.

Controller can not see the motor.

Could be a short circuit in the motor.

1. Check the resistance across the motor leads.

99 Under-voltage Cutback Baery voltage too low

Baery voltage < undervoltage threshold.

1. Bad connecon at baery or controller.

2. Check no corrosion on the baery terminals.

Quick checks if no reading on fuel gauge and machine does not operate:

1. Check 10A fuse in the control panel. Fuse holder is located to the right hand side of the main control panel, turn CCW to release the fuse holder.

2. Check main fuse located behind the rear motor housing cover & 100A fuse. Open the rear cover which is xed in posion with 2 x M6 screws, ensure the cover is

supported during this process. Main fuse is located on the le hand side of the baery housing.

When changing the 100 amp fuse, ensure that the posive baery lead is fully dis-connected. Electrical maintenance should be carried out by a qualied person.

To maximize the life of your AGM baery, it is important that it is

properly charged. As with all lead-acid baeries, both over- and under-

charging an AGM baery will result in shortened service life.

The C301 mini dumpers are ed with an on-board SMART charger

which maintains the baery full charge condion without resulng in

over charging.

The AGM baeries are sealed for life units and do not require any uid

top up.

Please read the following instrucons:

Charging system Inspecon

The charger’s AC (mains) cord should be free of breaks or cuts and the

wall plug socket should be clean and free from debris.

The cable connectors from the on-board charger should be clean and

properly mate with the baery terminals to ensure a sound connecon.

Baery Inspecon

• Check baery cables are not damaged.

• Connectors should be free of corrosion.

• DC Cable post or eyelet connectors are ght to avoid arcing.

Charging Guidelines

• Fully charge baeries aer baeries have been dis-charged to ¼ full on baery

gauge. The on-board charger mains cord should be plugged into the mains AC

supply. Leave baeries to complete full charge and do not disconnect unl fully

charged. Once fully charged the on-board SMART baery charger will maintain

the baery fully charged status.

• Do not opportunity charge baeries i.e. if the baeries have only dis-charged

to ¾ full on the baery gauge, there is no need to connect the charger to the

AC supply. It is recommended to use the C301 unl the baeries have dis-

charged to ¼ full on the baery gauge, then place the C301 onto a full charge

cycle.

• Charge in a venlated area as gasses may be released through the pressure

relief valve if the baeries are excessively over-charged.

• Never charge a frozen baery.

• Ideal charging temperatures: (0°C to 40°C) 32°F to 104°F

AGM Baery Charging

Loading...

Loading...