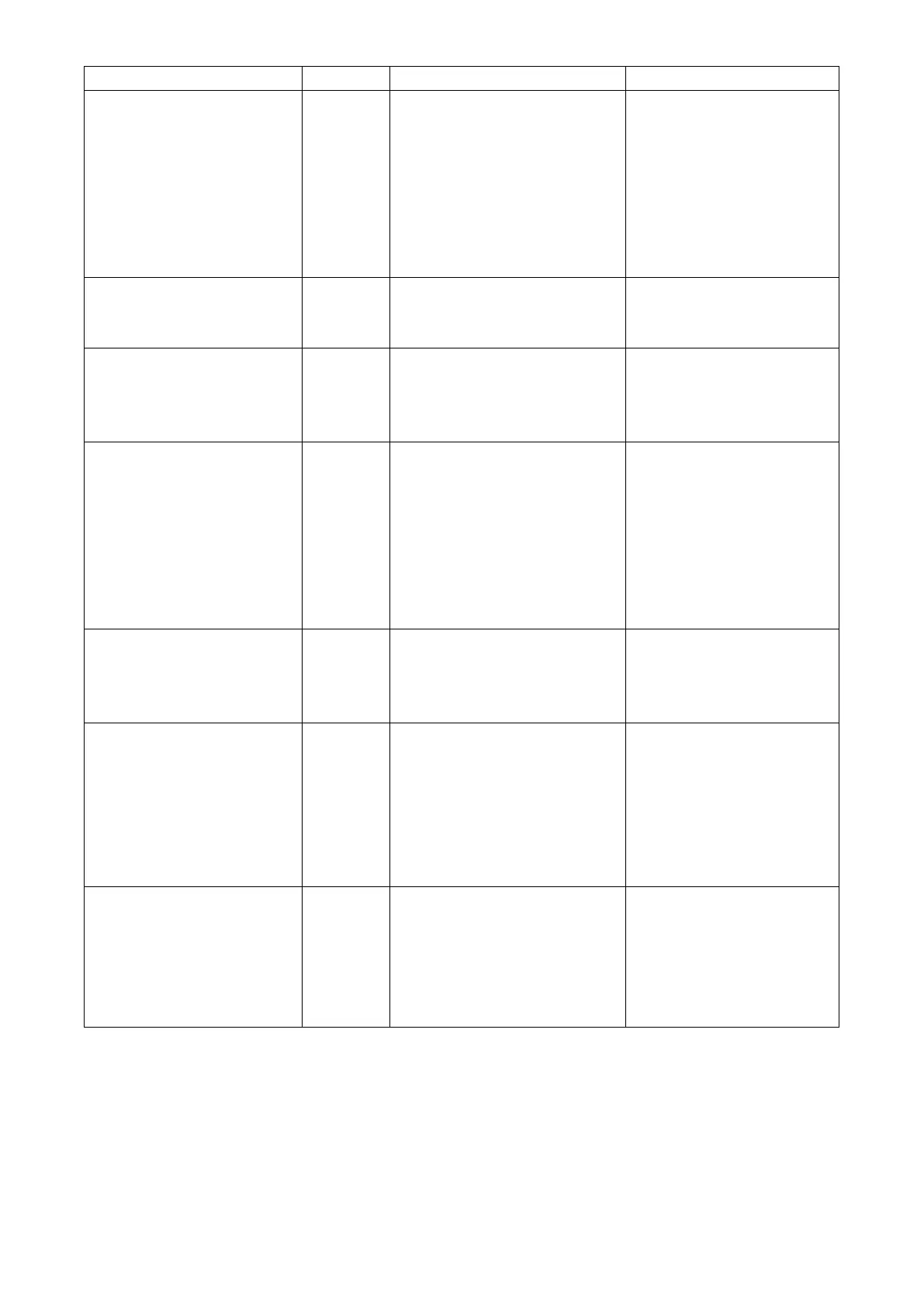

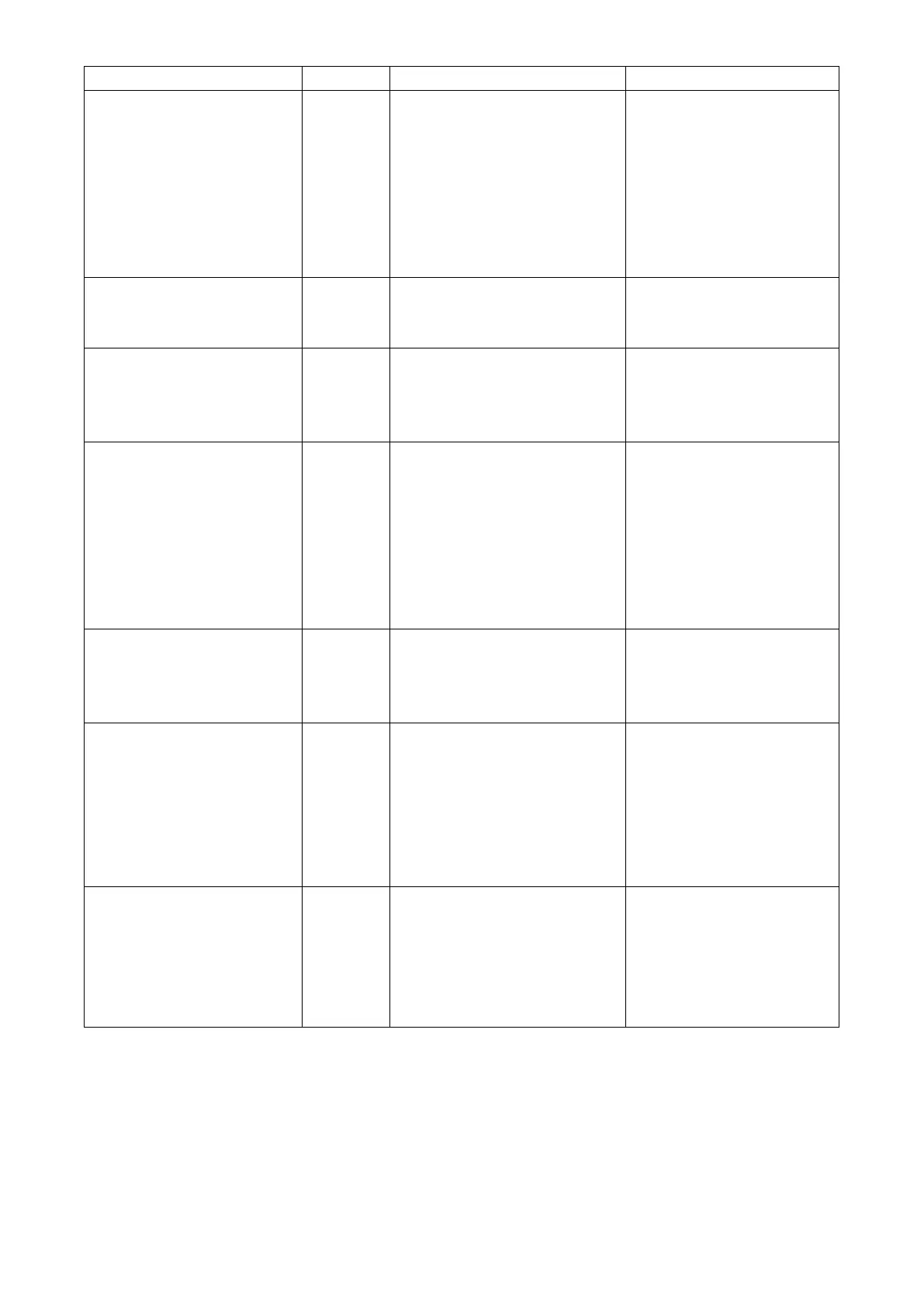

Communication failure

between controller and main

board

1. Poor signal wire connection or

damaged signal wire

2. Controller malfunction

1. Check and re-connect the

signal wire

2. Change a new signal wire

3. Turn off electricity supply

and restart machine

4. Change controller

Communication failure

between Main control board

and Driving board

1.

Poor connection of

communication wire

2. The wire is damaged

1. Check the wire connection

2. Change wire

VDC voltage too high protection

1.

Line voltage is too high

2. Driver board is damaged.

1.

Check if the power is in the

normal range

2. Change driver board or main

board

1. Data mistake

2. Wrong compressor phase

connection

3. Compressor liquid and oil

accumulation lead to the current

becomes larger

4. Compressor or driver board

damaged

1. Program error, turn off

electricity supply and restart

after 3 minutes

2. Change driver board

3. Check compressor sequence

connection

VDC voltage too low protection

1.

Mother line voltage is too low

2. Driver board is damaged.

1. Check if the power is in the

normal range

2. Change driver board

Input current over high

protection.

1. The compressor current is too

large momentary

2. The water flow is abnormal

3. Power fluctuations within a

short time

4. Wrong PFC inductor

1. Check the compressor

2. Check the waterway system

3. Check if the power is in the

normal range

4. Check if the correct PFC

inductor is used

IPM module thermal circuit is

abnormal

1. Output abnormity of IPM

module thermal circuit

2. Fan motor is abnormal or

damaged

Fan blade is broken

1. Change a driver board

2. Check if the motor speed is

too low or fan motor

damaged, change it.

3. Change fan blade

Loading...

Loading...