BERMAD Waterworks

700 Series

Model 720

Engineer Specifications

The Pressure Reducing Valve shall reduce higher upstream pressure to lower preset downstream pressure regardless of

fluctuating demand or varying upstream pressure.

Main Valve: The main valve shall be a center guided, diaphragm actuated globe valve of either oblique (Y) or angle pattern

design. The body shall have a replaceable, raised, stainless steel seat ring. The valve shall have an unobstructed flow path,

with no stem guides, bearings, or supporting ribs. The body and cover shall be ductile iron. All external bolts, nuts, and studs

shall be Duplex® coated. All valve components shall be accessible and serviceable without removing the valve from the pipeline.

Actuator: The actuator assembly shall be double chambered with an inherent separating partition between the lower surface

of the diaphragm and the main valve. The entire actuator assembly (seal disk to top cover) shall be removable from the valve

as an integral unit. The stainless steel valve shaft shall be center guided by a bearing in the separating partition. The replaceable

radial seal disk shall include a resilient seal and shall be capable of accepting a V-Port Throttling Plug by bolting.

Control System: The control system shall consist of a 2-Way adjustable, direct acting, pressure reducing pilot valve, a needle

valve, isolating cock valves, and a filter. All fittings shall be forged brass or stainless steel. The assembled valve shall be

hydraulically tested and factory adjusted to customer requirements.

Quality Assurance: The valve manufacturer shall be certified according to the ISO 9001 Quality Assurance Standard. The main

valve shall be certified as a complete drinking water valve according to NSF, WRAS, and other recognized standards.

Operation

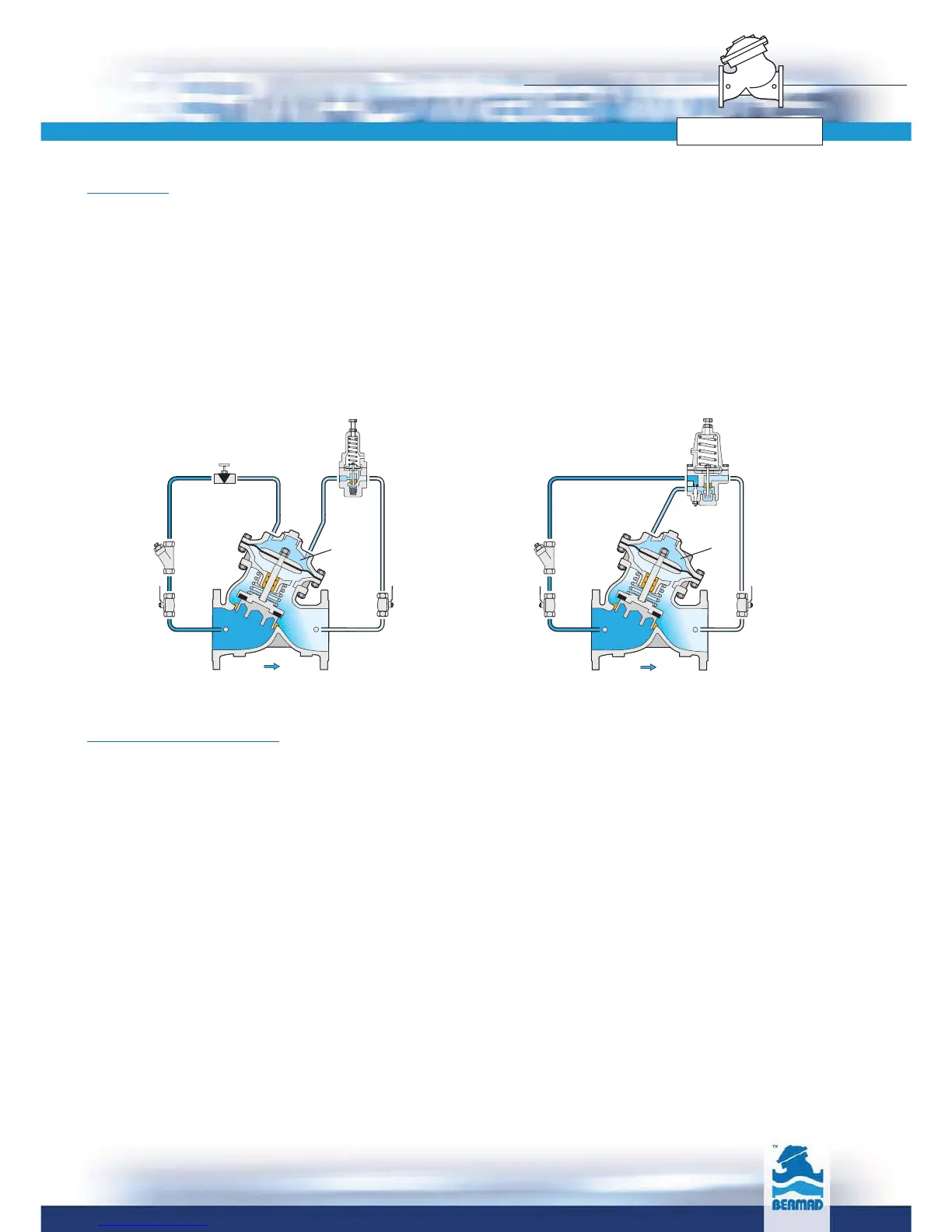

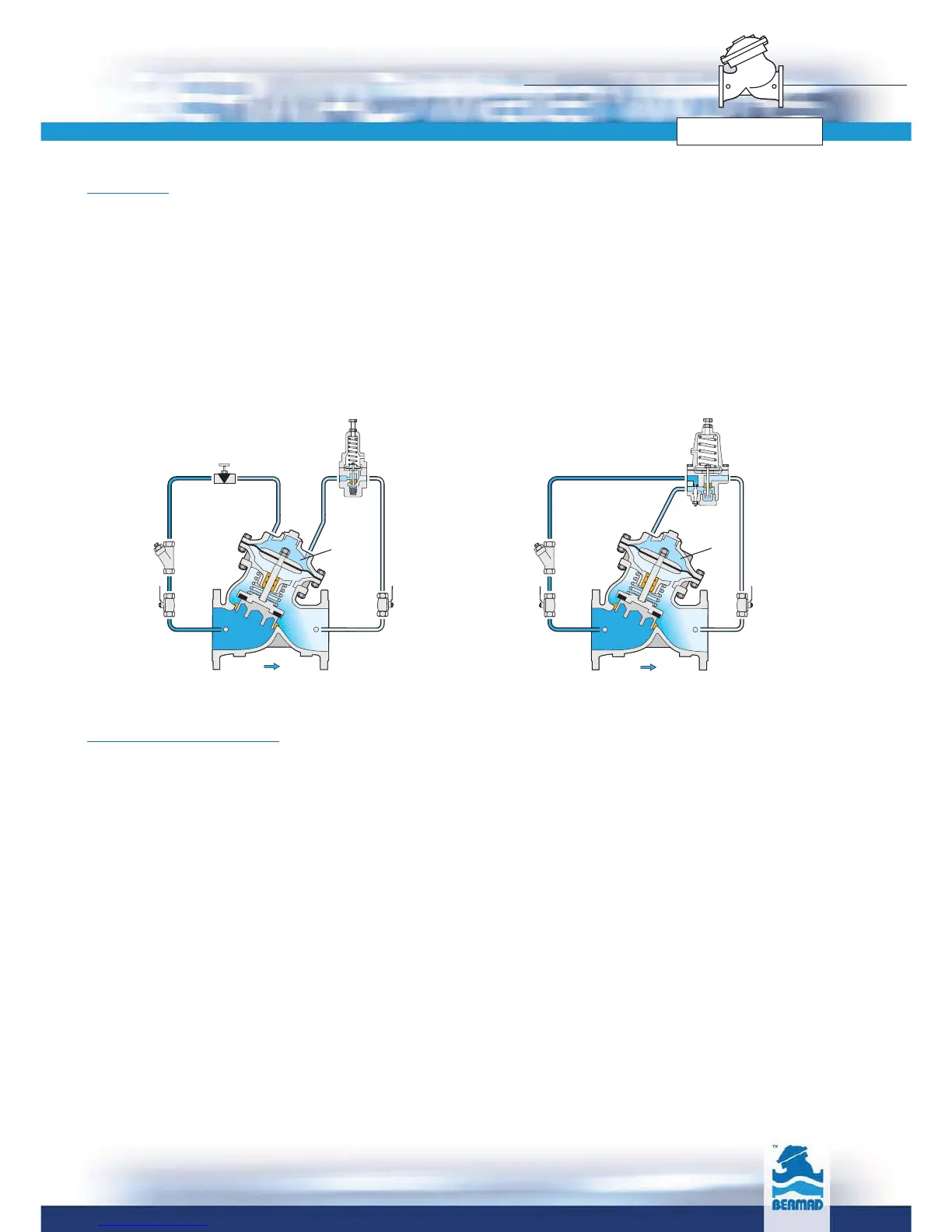

The Model 720 is a pilot controlled valve equipped with an adjustable, 2-Way pressure reducing pilot.

The needle valve

[1] continuously allows flow from the valve inlet into the upper control chamber [2]. The pilot [3] senses

downstream pressure.

Should this pressure rise above pilot setting, the pilot throttles, enabling pressure in the upper control chamber to accumulate,

causing the main valve to throttle closed, decreasing downstream pressure to pilot setting.

Should downstream pressure fall below pilot setting, the pilot releases accumulated pressure, and the main valve

modulates open.

The integral orifice between the lower control chamber and valve outlet moderates valve reactions.

The needle valve controls the closing speed. The downstream cock valve

[4] enables manual closing.

1

1

/2-10”

with #2PB Pilot

6-14”

with #2 Pilot

➊

[3]

[2]

[1]

[3]

[2]

[1]

[4] [4]

Note: For 16" and larger valves,

see "Pilot Valve Selection" table at the last page.

Loading...

Loading...