Pag. 47 / 49

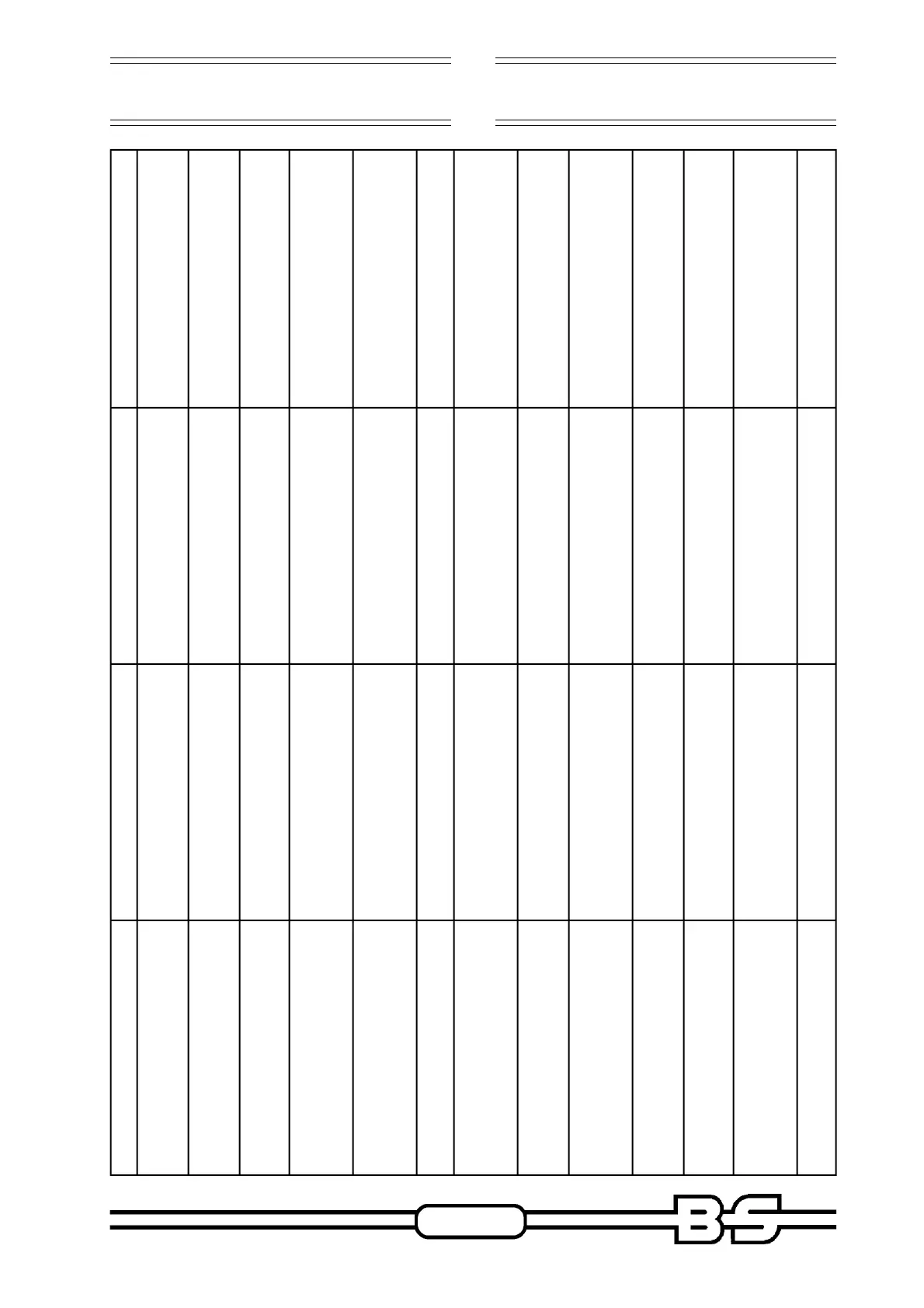

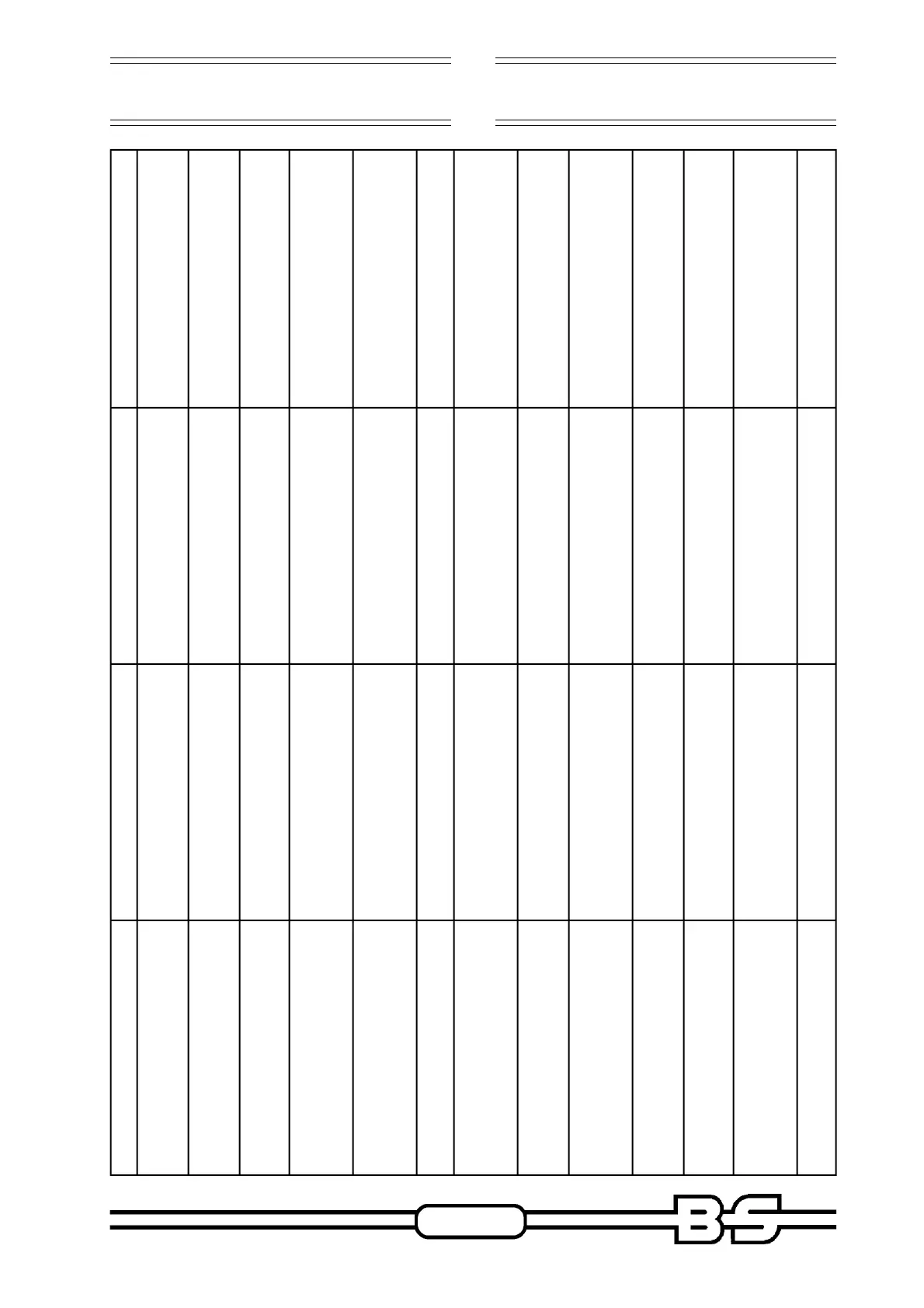

ANOMALY CAUSE EFFECT ACTIONS

The safety valve doesn’t open because of

an installation mistake.

Wrong installation of the valve on the system

(i.e. connection to the system of the outlet

side instead of the inlet side).

The pressure of the plant increases over

than the fixed security limits.

Stop the system, remove the valve and

install it properly. Refer the problem to the

plant Security Manager.

Leakage (1). Seat and/or disc surfaces damaged because

of foreign matters presence (i.e. welding

residuals).

Fluid loss Stop the system and contact Besa Technical

Assistance.

Leakage (2).

Leakage (2). The operating pressure of the system is 90%

higher than the set pressure of the safety

valve.

Fluid loss. Stop the system and contact Besa Technical

Assistance.

Leakage (3).

Due to excessive vibration of the system.

Pulsating flow of medium.

Induced vibrations for mechanic causes.

Fluid loss and possible damage of seat

and/or disc tightness surfaces.

Stop the system and contact Besa Technical

Assistance.

Insufficient discharge capacity respect what

declared or estimated (1).

Fluids are different than the previously

indicated and considered.

The pressure of the plant increases over

than the fixed security limits.

Stop the system and contact Besa Technical

Assistance.

Insufficient discharge capacity respect what

declared or estimated (2).

Wrong dimensioning of the safety valve

because of a calculation mistake or wrong

information received from the

Customer/User.

The pressure of the plant increases over

than the fixed security limits.

Stop the system and contact Besa Technical

Assistance.

The pressure of the plant increases over

than the fixed security limits.

Stop the plant, remove the gag test and refer

the problem to the plant Security Manager.

“Floating”, hammering-in of the disc on

the seat.

Excessive built-up back pressure during

safety valve discharge, or excessive load

loss at the inlet (higher than 3% of the set

pressure).

Seat and/or disc surfaces damages and

reduced discharge capacity that causes a

possible increase of the pressure over than

the fixed limits.

Stop the system and contact Besa Technical

Assistance.

Delayed opening.

Excessive built-up back pressure. The pressure of the plant increases over

than the fixed security limits.

Check the dimensioning of the discharge

conveyance system and contact Besa

Technical Assistance.

Stop the system and contact Besa Technical

Assistance.

The blow down of safety valve is over than

the foreseen limit.

Overheating of the spring because the

construction material is not suitable and

because of the continuous and extended

leakage of the fluid.

Excessive discharge of the fluid and risk of

system stop.

Contact Besa Technical Assistance.

Unsuccessful closing.

Unsuccessful closing. Presence of foreign matters between seat

and disc i.e. due to the fragmentation of

rupture discs.

Loss of dangerous and/or expensive fluids

and system stop.

Contact Besa Technical Assistance.

Rupture of valve-body under stress. Operating conditions don’t match the

design data indicated on Besa Inspection

Certificate.

Loss of fluid and possible damages to

persons or things.

Stop the system and contact Besa Technical

Assistance.

Breakage of valve-body and/or of

connection pipe of the valve to the system.

Stresses caused by external loads, i.e.

thermal expansion.

Loss of fluid and possible damages to

persons or things.

Stop the system and contact Besa Technical

Assistance.

Breakage of valve-body and/or of

connection pipe of the valve to the system.

Breakage of valve-body and/or of

connection pipe of the valve to the system.

Corrosion caused by the fluid type or by the

environment conditions.

Loss of fluid and possible damages to

persons or things.

Stop the system and contact Besa Technical

Assistance.

Loading...

Loading...