Do you have a question about the Beta Marine Beta 25 and is the answer not in the manual?

Identifier for Beta Marine Works Order Card, crucial for spare parts.

Unique identifier stamped on the engine for tracking and support.

Inspect engine immediately on delivery for damage and report within 24 hours.

Store engine in a dry, frost-free area; inhibit if stored for over six months.

Covers engine cleanliness, guarding, fuel, oil, scalding, and lifting safety.

Details technical data including cylinder count, bore, stroke, power, and weight.

Ensures adequate air flow for engine cooling and combustion.

Guidelines for preventing overheating in keel-cooled engine systems.

Ensures vibration-free operation by proper alignment and mounting.

Maximum allowable angles for engine installation and oil level checks.

Ensures correct angular positioning between engine and propeller shaft.

Ensures correct parallel positioning between engine and propeller shaft.

Details R&D and CentaFlex couplings for absorbing torsional vibrations.

Guidance on preventing water ingress into the engine from the exhaust.

Methods to prevent cooling water entering the engine via the exhaust.

Installation and maintenance of anti-syphon valves for exhaust safety.

Proper placement to prevent water backflow and ensure drainage.

Proper selection and installation of sea water inlets and strainers.

Connecting the stern gear lubrication system to the engine.

Minimum clearance between propeller and hull to reduce noise.

Matching exhaust hose diameter to engine model for emission compliance.

Maintaining minimal exhaust back pressure for engine performance.

Ensuring proper installation to prevent water ingress and manage heat.

Details required pipe sizes and connector types for various systems.

Proper setup of fuel supply, leak off, and filter systems to prevent air.

Instructions for filling and ensuring all air is removed from the calorifier system.

Guidelines for keel cooling tank surface area and construction for narrowboats.

Location, wiring, and protection requirements for control panels.

Recommendations for dedicated starter and domestic battery banks.

Overview of battery types and factors affecting selection for marine use.

Guidelines for selecting appropriate cable sizes to minimize voltage drop.

Essential checks including fluid levels, battery, and cable connections before starting.

Step-by-step guide for starting engines using keyswitch panels.

Procedure for starting engines using water-resistant push-button panels.

Methods for stopping the engine, including electrical and mechanical methods.

Routine checks required for daily operation or every 8 hours.

Specific maintenance tasks after the initial 25 hours of operation.

Maintenance tasks to be performed after the first 50 hours.

Maintenance schedule for engines with shallow sumps at 150 hours.

Routine yearly or 250-hour service checks and replacements.

Major service tasks required every 750 hours of operation.

Details on API classification, SAE grades, and oil types for engine lubrication.

Procedure for correctly checking and topping up the engine oil level.

Steps for draining and replacing engine oil and oil filter.

Procedure for checking and topping up the gearbox oil level.

Instructions for replacing the spin-on fuel filter cartridge.

Description of how heat exchanger cooling systems function.

Requirements for fresh water and anti-freeze mixture as coolant.

Explanation of keel cooling, noting Beta Marine does not offer raw water cooling.

Step-by-step guide for filling and bleeding the fresh water cooling system.

Procedure for checking and replacing the sea water pump impeller.

Maintenance for cleaning the heat exchanger tube stack and replacing zinc anodes.

Procedure for checking and adjusting belt tension on the alternator.

Guidance on checking and changing the air intake filter.

Includes panel protection, battery checks, and loose terminal connections.

Protecting the engine and systems for winter or extended lay-up.

Steps for preparing the engine for storage when ashore.

Solutions for when the starter motor turns but the engine doesn't start.

Troubleshooting for slow or non-cranking starter motor issues.

Causes and solutions for reduced engine power output.

Troubleshooting for unstable engine running, including idle and high speeds.

Diagnosing white, blue, or black exhaust gases.

Troubleshooting low oil pressure indicators during operation.

Identifying causes for high oil usage and water contamination in oil.

Diagnosing water contamination in lubricating oil for different cooling systems.

Common reasons for engine overheating across all cooling types.

Specific causes and checks for overheating in heat exchanger systems.

Troubleshooting overheating in keel cooling and rapid battery discharge.

Resolving problems with Morse controls, rev counters, and transmission noise.

Identifying and resolving sources of engine vibration.

Diagnosing and fixing causes of knocking noises from the engine.

Fault finding for panels with keyswitches and indicator lamps.

Troubleshooting for keyless panels with push-button controls.

Troubleshooting when no warning lamps or buzzer function, and engine won't start/stop.

Diagnosing issues with specific warning lamps like water temperature.

Troubleshooting for buzzer and starter battery charge lamp faults.

Diagnosing faults with the tachometer and domestic charge indicators.

Specific electrical fault finding for C Deluxe and B panels.

Troubleshooting for engines wired to non-Beta control panels.

Checking connections for panel extension harnesses.

Checks for insulated earth return systems where the engine may not operate.

Torque values for standard nuts and bolts used on the engine.

Torque values for specific engine components like head bolts and glow plugs.

List of available wiring diagrams with part numbers and page references.

Manufacturer's declaration regarding compliance with EU directives.

Details engine family codes and EC type certificate numbers for compliance.

Ensuring engine operation meets emission standards under Recreational Craft Directive.

List of common parts with part numbers for Beta 10-25 engines.

List of control panels, extensions, sensors, and related accessories.

Parts list for anodes, filters, pumps, belts, and alternators.

Table to record maintenance services, dates, and responsible parties.

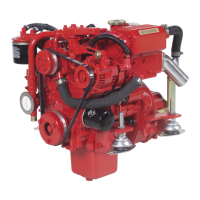

| Engine Type | Diesel |

|---|---|

| Cylinders | 3 |

| Power Output | 25 hp (18.4 kW) |

| Cooling System | Heat exchanger |

| Fuel System | Indirect injection |

| Bore x Stroke | 76 mm x 82 mm |

| Rated RPM | 3600 RPM |

Loading...

Loading...