Bettis P/N 137462E

Revision "A”

Page 4 of 18

1.6 LUBRICATION REQUIREMENTS

1.6.1 The actuator should be re-lubricated at the beginning of each service interval using

the following recommended lubricants.

NOTE: Lubricants other than those listed in steps 1.6.2 should not be used without prior written

approval of Bettis Product Engineering.

1.6.2 All temperature services

(-50°F to

+350°F)/(-45.5°C to 176.6°C) use Bettis ESL-5

lubricant. ESL-5 lubricant is contained in the Bettis Module Service Kit in tubes and the

tubes are marked ESL-4,5 & 10 lubricant.

1.7 GENERAL TOOL INFORMATION

1.7.1 All threads on CBA series actuators are Inch Unified and NPT.

1.7.2 All tools/Hexagons are American Standard inch.

1.7.3 Suggested tools: Two adjustable wrenches, small standard screwdriver with sharp

edges rounded off, medium size standard screwdriver, external snap ring pliers, drive

ratchet / deepwell socket set and torque wrench (up to 3,000 inch pounds / 339 N-m).

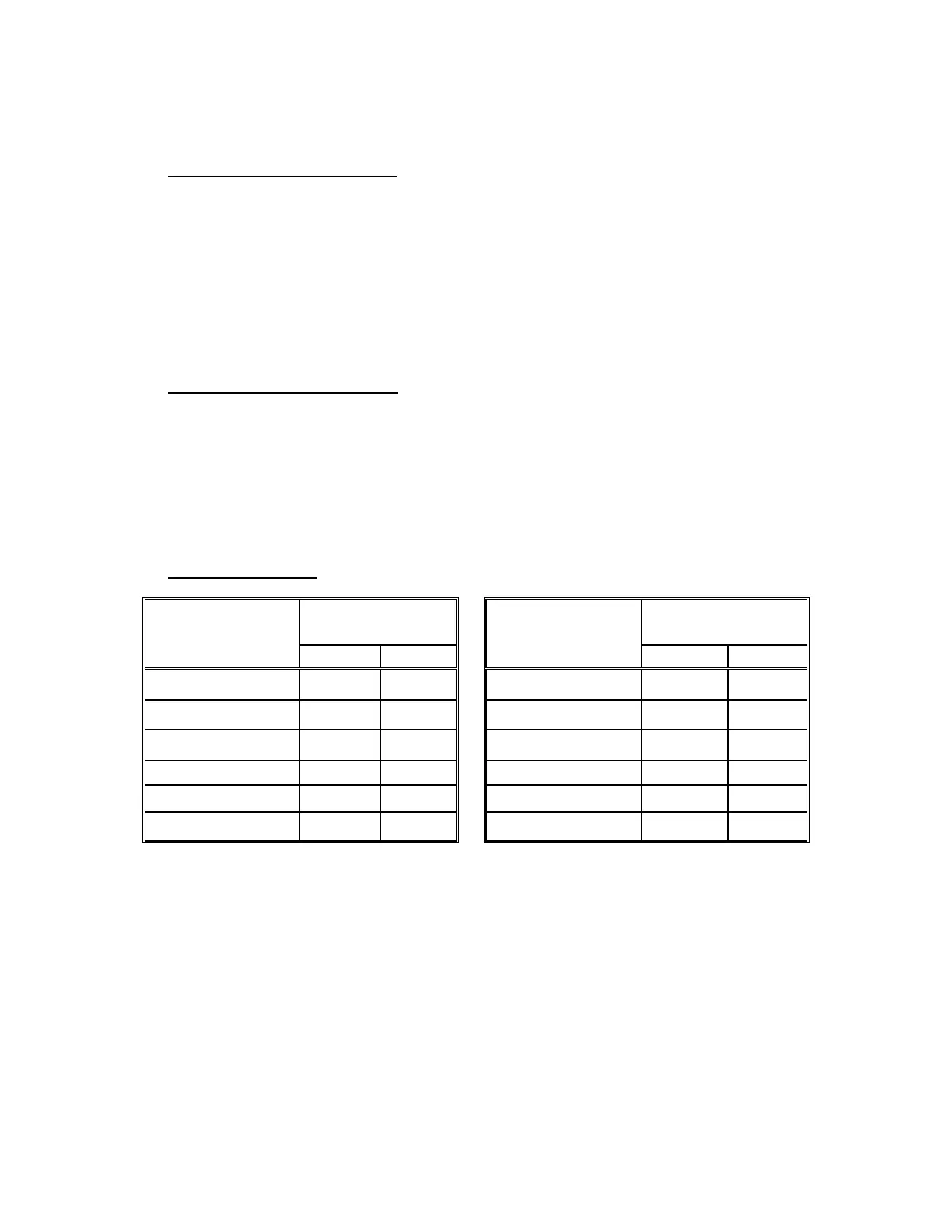

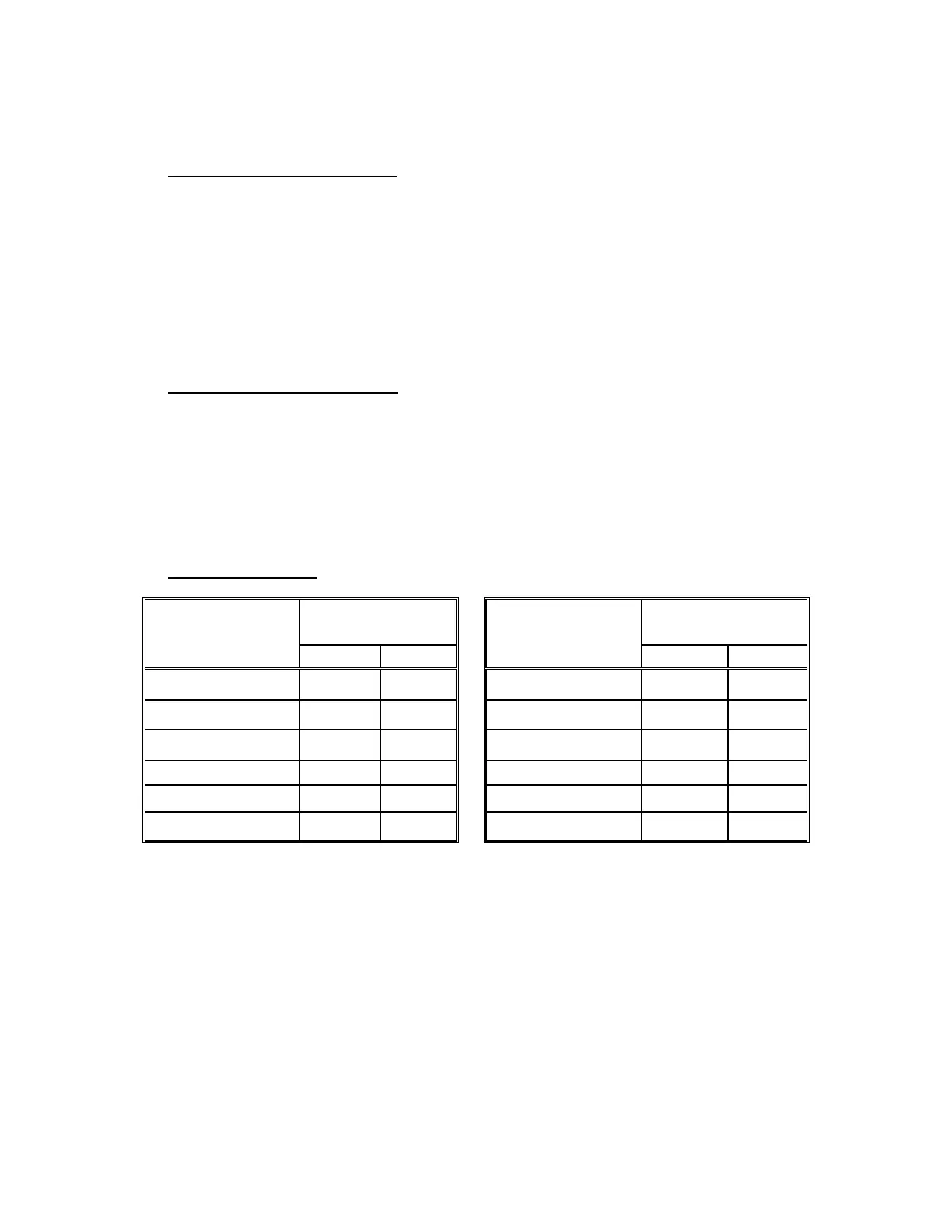

1.8 ACTUATOR WEIGHT

ACTUATOR APPROXIMATE ACTUATOR APPROXIMATE

MODEL WEIGHT (1)

MODEL WEIGHT (1)

LB KG

LB KG

CBA730 130 59 CBA930 155 70.4

CBA730-M3 131 59.4 CBA930-M3 158 71.7

CBA730-M3HW 131.5 59.6 CBA930-M3HW 158.5 71.9

CBA830 140 63.5 CBA1030 170 77.1

CBA830-M3 143 64.9 CBA1030-M3 173 78.5

CBA830-M3HW 143.5 65.1 CBA1030-M3HW 173.5 78.7

NOTES: (1) Weight is for bare actuator without accessories or valve adaptation.

Loading...

Loading...