3

2.1 Prior to taking the machine into service

Before connecting the tool to a power source, be sure the voltage supplied is the same as specied on the name plate

of the tool. The power supply should not vary more than 10% above or below the voltage indicated on the name plate.

Working with worn or damaged bevel heads will cause the machine to fail.

• Check bevel head prior to use.

• A sharp bevel head will increase cutting speed and machine life.

• The bevel head must be changed regularly.

• The bevel head must be mounted centrally and positioned against the limit stop.

• The maximum allowable speed of the tool and of the chuck may not be exceeded under any circumstances.

• Observe national regulations.

2.2 Taking the machine into service

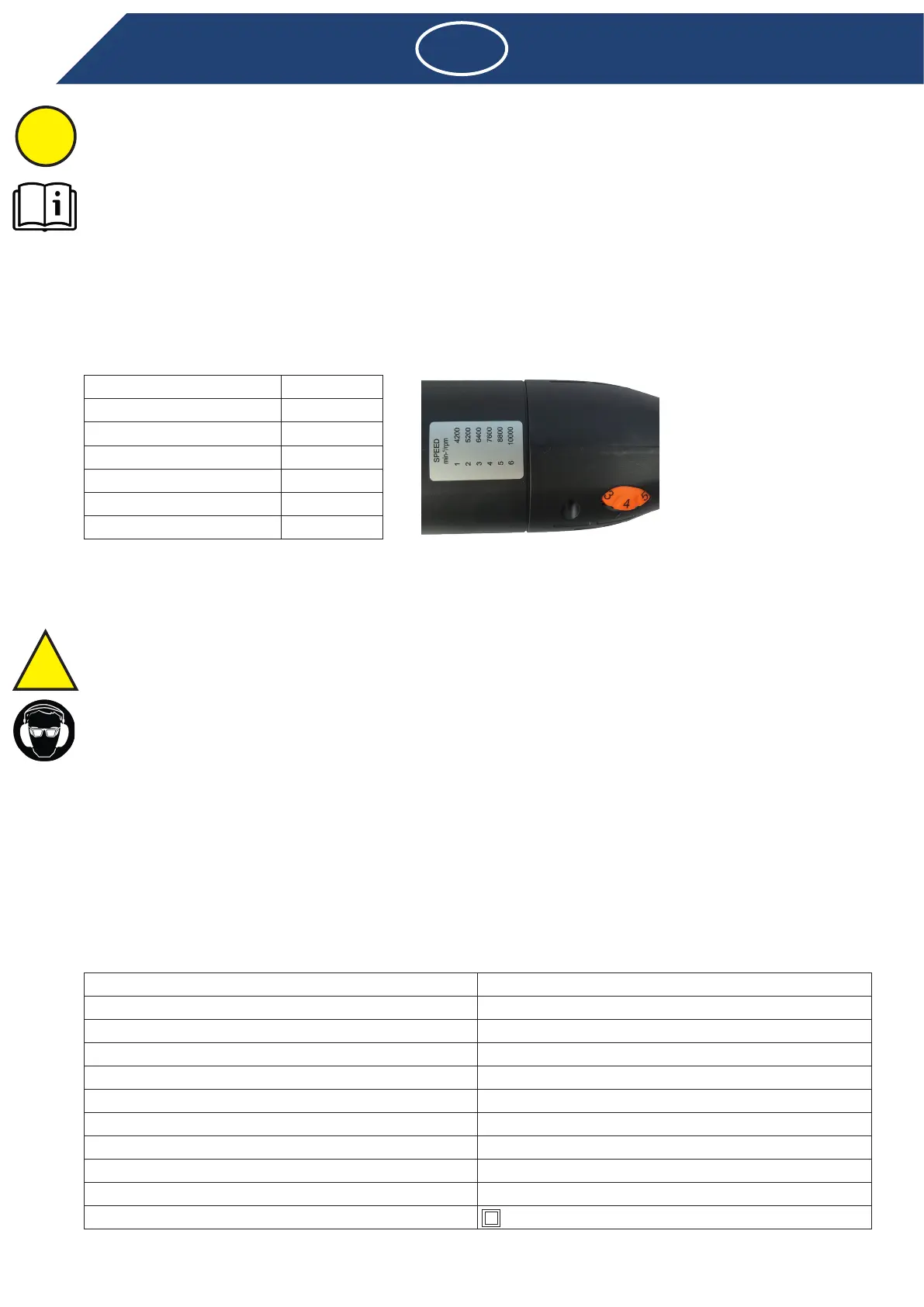

Preselect speed with adjusting wheel according to speed table.

Adjusting wheel increment Min

-1

/ rpm

1 4.200

2 5.200

3 6.400

4 7.600

5 8.800

6 10.000

During operation, never increase the speed of the machine to above that of the maximum admissible speed of the

grinding tool!

2.2.1 Turn on

• Always wear protective clothing, safety shoes, safety glasses and ear protection.

• Make sure you always have a rm footing when working with the machine.

• Whatever the position of the machine, always use two hands to control the machine.

• Never touch the bevel head when the machine is running.

• Never use the machine above head height.

• The machine should only be used for conventional up-cut milling.

• To turn the machine on, press the ON/OFF handle and hold.

• Bring the machine slowly into contact with the work piece only after the selected tool speed has been reached.

• When cutting a bevel, always move the machine from left to right against the rotation direction of the bevel head.

• When machining bore holes, always work in a clockwise direction.

2.2.2 Turn off

• Take beveling machine from work piece and turn off.

• Motor stops.

2.3 Rating data

Power voltage (cf. replacement parts list) 120/230V; 50/60 Hz; 120/230V

Power Input 1530 W

Power Output 1000 W

No-load speed 10500 min

-1

/rpm

Max. wheel diameter 45 mm

Grinding spindle thread M8

Sound pressure level according to EN 60745 89 dB (A) K = 3 dB

Noise emission level 100 dB (A) K = 3 dB

Vibration according to EN 60745 <2.5 m/s2 K = 1.5m/s2

Weight w/o cord set 4.3 kg

Protection class / II

!

i

EN

Loading...

Loading...