6

© ITW FINISHING SYSTEMS AND PRODUCTS

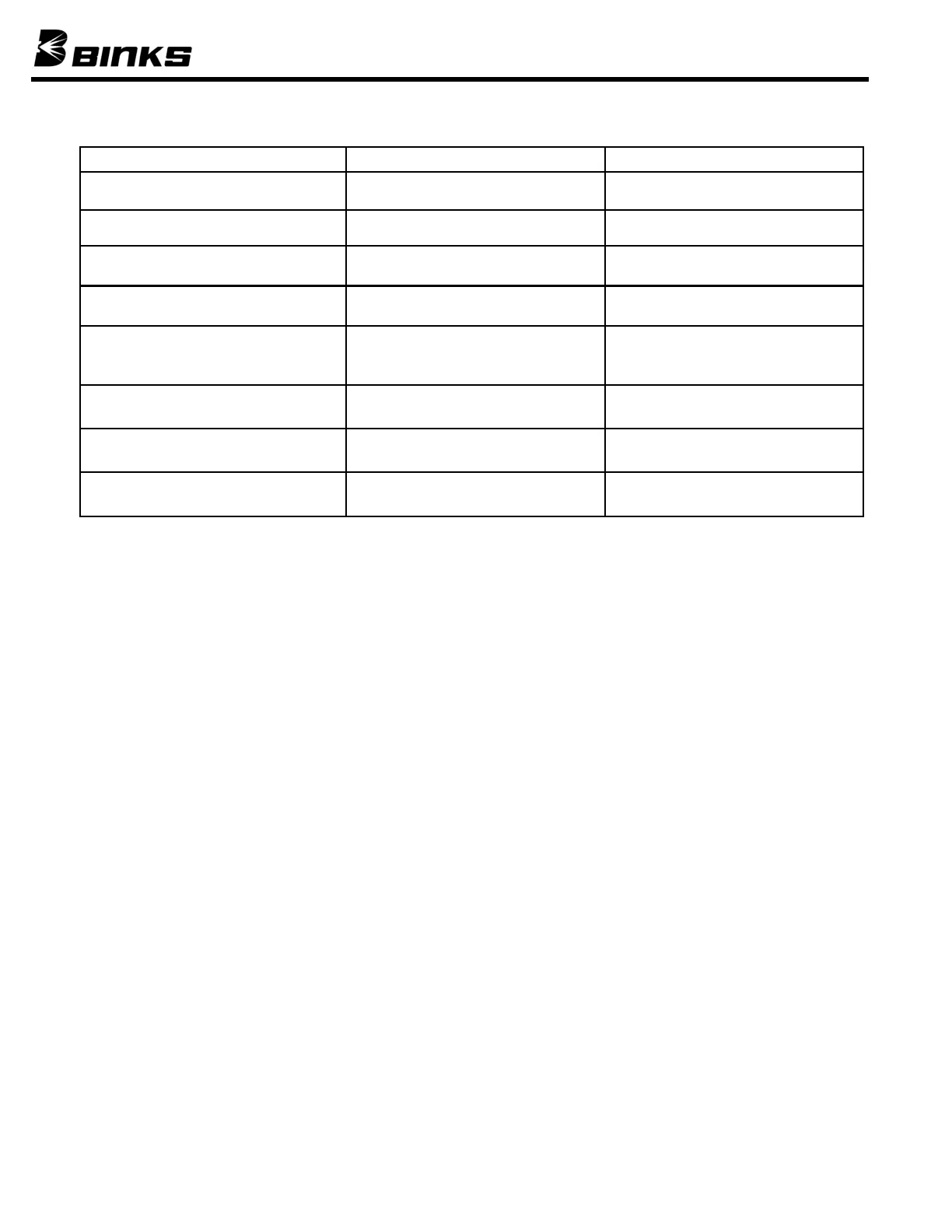

SERVICE CHECKS

FAULT CONDITION CAUSE CORRECTION

Air escaping from port on regulator cap. Broken or damaged diaphragm Replace diaphragm.

Pressure creepage registered on gauge. Dirty or worn valve seat in regulator. Clean or replace valve seat.

Material tends to sele out rapidly. Not enough agitaon of material. Increase agitaon.

Air leakage at agitator seal. Defecve seal assembly. Replace.

Paint geng into bearing assembly of

agitator.

Paint level in tank too high.

Defecve agitator sha seal.

Keep uid level under bearing ass’y.

Replace.

Fluid or air leak at lid gasket. Thumb screw not ght.

Defecve lid gasket.

Tighten.

Replace.

Fluid or air leak at ll port gasket. Fill port cap not ght.

Defecve ll port gasket.

Tighten uid tube into lid.

Reduce speed of agitator.

Air mixing with paint Fluid tube not sealed to lid.

Excessive agitaon.

Tighten uid tube into lid.

Reduce speed of agitator.

FOR FURTHER SAFETY INFORMATION REGARDING BINKS AND DEVILBISS EQUIPMENT, SEE THE

GENERAL EQUIPMENT SAFETY BOOKLET (77-5300).

Loading...

Loading...