5. Gear shifting

4 gear shifting

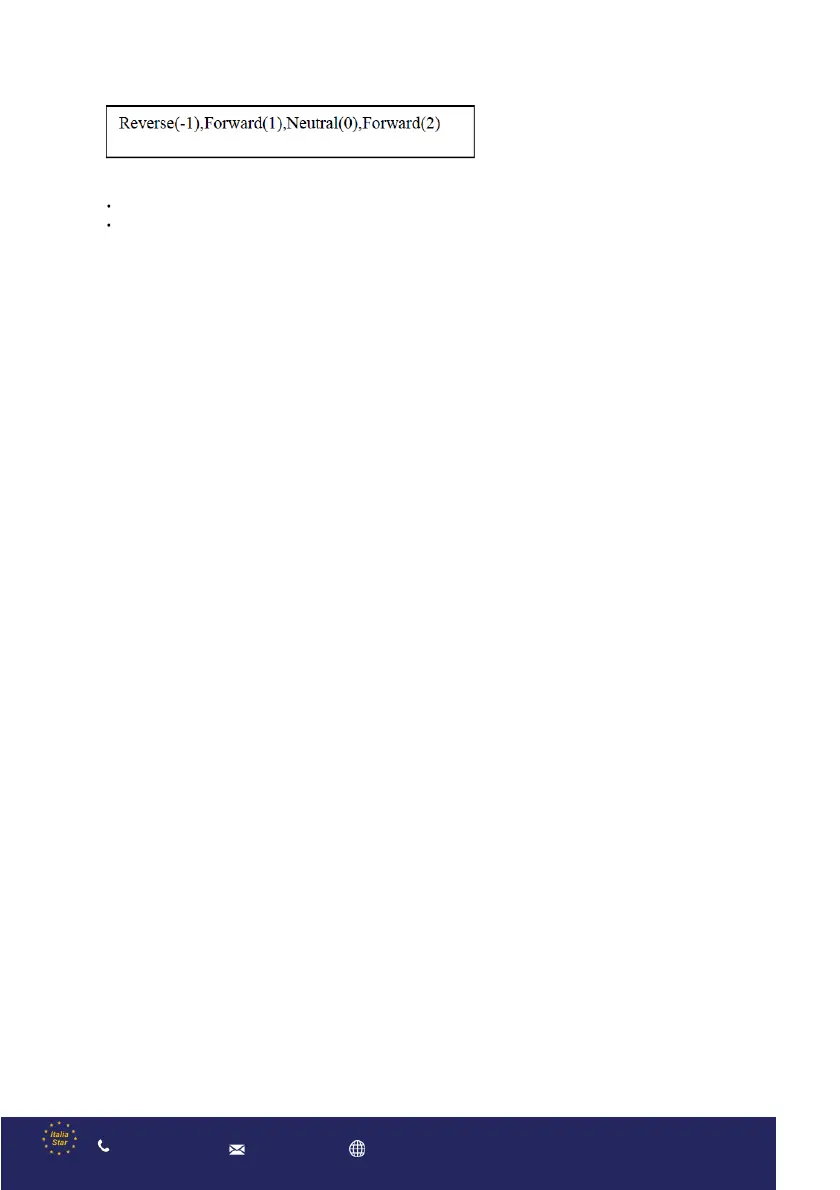

The way of gear changes

1) Put the throttle switch to the left (a minimum position) Gear shifting

by a clockwise rotation

2) Loose the clutch handle to make the clutch separate

3) Clench the clutch handle bar. Then the power tiller will work on the different gear shifting, and

then step on the gas to the new speed as inquired.

Chapter Four Maintaining Methods

Because of running, friction and load change, inevitably produce connection bolt looseness,

parts damage phenomenon, which make the system's correct state destroyed, the engine’s

power decline, fuel consumption increase, increases the normal use of power tiller. In order to

reduce the occurrence of the above situation, we must strictly, regularly do the maintenance work

well. To keep the micro tillage machine in good technical shape and prolong its service life.

1、Running-in

1. the running of diesel engine pls consult it’s user manual.

2. new power tiller or repaired power tiller, should work for 1 hour in zero load condition. After

5 hours light load working, run out the whole lubricating oil of the transmission and crankcase of

diesel engine at once while the temperature is hot, and then conduct 4 hours running-in as per

the fourth demands.

2、The technical maintenance

1. Per shift maintenance (before running and after running every time)

1) Listen and observe the abnormal phenomenon( like abnormal sounds, overheating and bolt

failure)

2) Check the Oil leakage status of engine, transmission and walking box.

3) Check the oil lever of engine and transmission, if it is within the limits of oil scale

4) Timely clean the dirt, weeds, oil pollution of the power tiller.

5) Write down the tillage record.

2. First class maintenance (ever 150 hours)

1) Conduct the whole contents of per shift maintenance.

2) Clean the transmission and crankcase, and change the oil

3. Check the clutch, shift gear and reverse gear system.

3. Second class maintenance (ever 900 hours ).

1) Check the whole contents of working for 150hours,

2) Check all the gear, bearing, if wearing serious, pls change the parts.

3) Other parts like rotary blades or bolt of the power tiller, if any, pls change it.

4. Technical checking (1500-2000 hours)

1) Ask professional personnel to check the friction plate and clutch.

5. Maintenance of gasoline power tiller.

Italia Star Com Due S.R.L.

Loading...

Loading...