8 BLACKRIDGE 2.5HP AIR COMPRESSOR BLACKRIDGE 2.5HP AIR COMPRESSOR 9

To drain oil

1. Loosen and remove the drain bolt and drain oil into a funnel / bottle and

dispose of in an appropriate manner.

2. Once drained, replace and tighten the drain bolt.

3. Wipe up any oil spills.

4. Fill up to the top red dot on the sight glass with fresh clean oil.

NOTE: Use oil type SAE30.

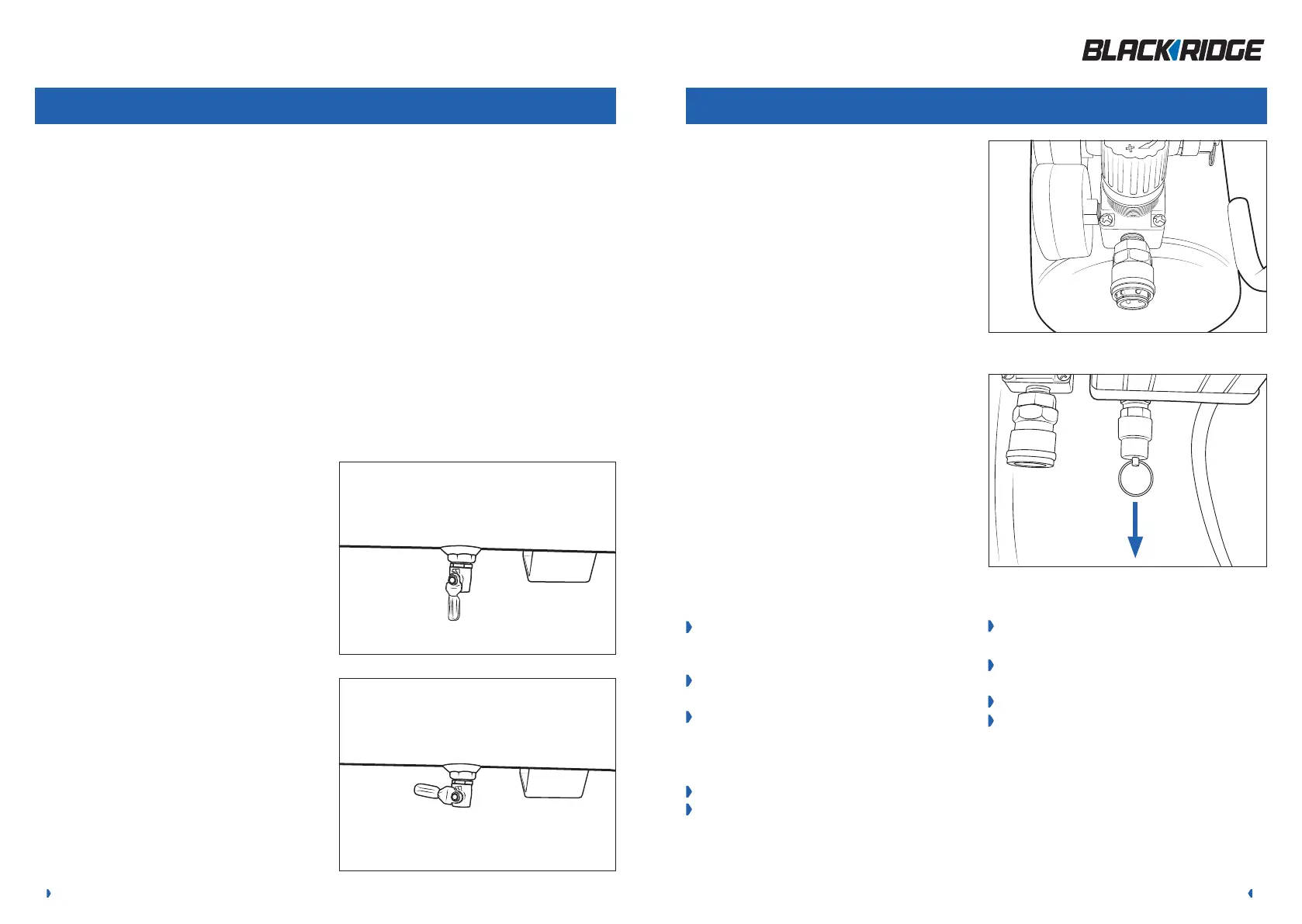

PIC. 12

Drain tap

After use, slowly open the drain tap to drain excess air and any

moisture. The excess air will also help purge the moisture. Leave

the drain tap open when air compressor is not in use, so any

moisture can continue to drain.

To open the drain tap pull the lever down to vertical. Pic. 12.

To seal the drain tap push the lever up to horizontal. Pic. 13.

NOTE: Remember to seal the drain tap before starting the

air compressor.

5. MAINTENANCE

PIC. 13

Daily: before use After use After every 50 hours of use

1. Check the oil level. 1. Disconnect from main power. 1. Replace the air filter.

2. Seal the tank drain

tap.

2. Open the tank drain

tap.

2. Drain oil completely and replace

with fresh oil.

3. Check safety valve operation. 3. Wipe down the air compressor.

4. Store safely and securely.

Air fitting outlet

This air compressor is fitted with a ‘Nitto style’ (female) socket.

1. Slide the outer collar backwards.

2. Push in the ‘Nitto style’ male plug (not included).

3. Release the collar.

4. Fully and completely push the ‘Nitto style’ male plug

(not included) into the ‘Nitto style’ female socket

until it clicks and outer collar moves forward.

Note: This air compressor has a maximum pressure of 8

bar. Always regulate the air pressure to match your air tool.

Different air tools require different operating pressures. Always

check with the tool manufacturer if unsure.

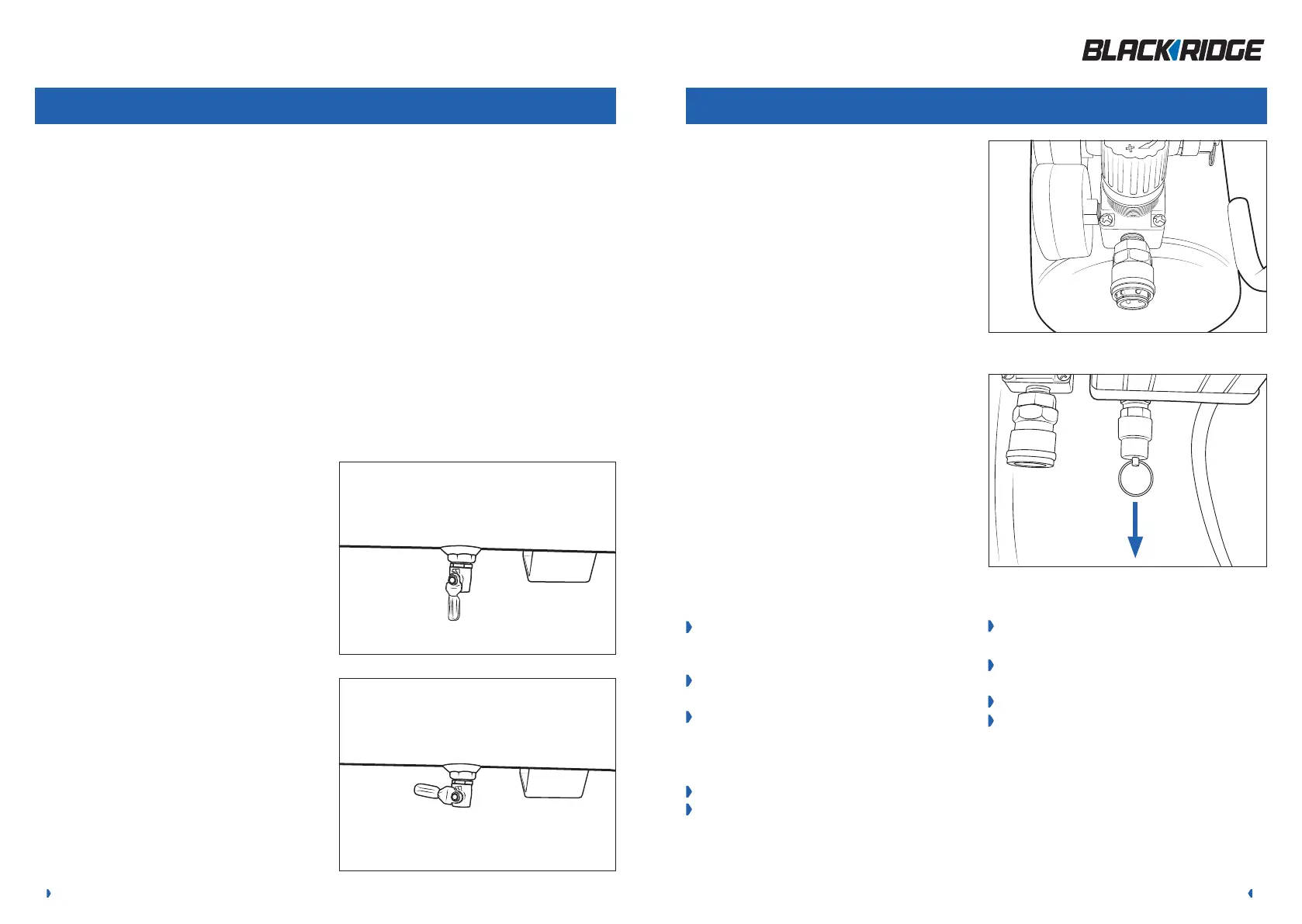

Safety valve

NOTE: When checking the safety valve ALWAYS wear safety

glasses.

To check the operation of the safety valve the air tank will need

to be full. Gently pull the ring outwards. This should release air

under pressure. Release the ring and this should stop the air

out flow immediately, once pressure decreases, Pic. 15.

If the safety valve does NOT work in this manner, STOP the air

compressor immediately and have the air compressor checked

/ serviced by an authorised service facility.

PIC. 14PIC. 14

PIC. 15PIC. 15

PIC. 14

PIC. 15

TROUBLESHOOTING

If your air compressor does not start

Check that you have plugged the power lead into a

standard 240V 10Amp power point and turned the

switch ON.

Check that you have turned on the air compressor

by lifting the ON/OFF button UP.

The air tank may be full. Use your air tool and the

air compressor should start when the pressure

decreases to 85PSI.

If your air compressor does not build up pressure

Check that the tank drain tap is sealed.

Air filter could dirty or blocked, replace air filter.

If these tips do not work please have your unit

checked by an authorised service centre.

Call SMART MARKETING GROUP PTY. LTD.

for your closest centre:

AUSTRALIA: 1300 660 457

NEW ZEALAND: 0800 474 876

If your air compressor smells like burnt oil

Check the oil level as it may be low.

If your air compressor does not hold pressure

Check your hose and tool for leaks and

fix as appropriate.

Check that drain valve is sealed.

Check Nitto style fitting with soapy water mix and if

bubbles then call Smart Marketing Group for options.

OPEN

CLOSED

PULL TO CHECK

Loading...

Loading...