Why is my Boart Longyear Drill losing front-end cushion?

- JJenna RichardsonJul 25, 2025

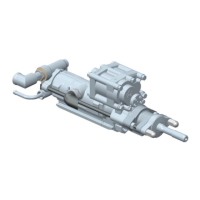

A loss of front-end cushion in your Boart Longyear Drill can occur due to a worn piston or a worn front cylinder washer. Replace the piston and check for outer flange wear. Also, check and replace the front cylinder washer, and then check the cushion.