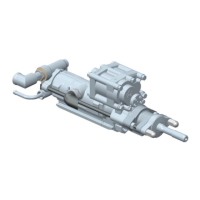

The S36 Rockdrill is a percussive drilling equipment manufactured by Boart Longyear, a company with over 125 years of experience in the design, manufacture, and operation of such equipment. This manual provides detailed information for service technicians to achieve maximum operating performance, including parts lists, maintenance procedures, testing, troubleshooting, and drilling instructions.

Function Description

The S36 Rockdrill is designed for percussive drilling operations. It utilizes a combination of rotation, percussion, and feed mechanisms to drive drill steel into rock. Water flushing is used to clear cuttings from the hole. The drill is intended for professional use in various drilling applications.

Important Technical Specifications

While specific detailed technical specifications like power output or weight are not explicitly listed in the provided excerpts, the manual does mention several key operational and maintenance parameters:

- Air Pressure: A test bench facility with 90 psi (620 kPa) air connection is required for testing. For operation, air lines and valves should maintain a minimum of 90 psi (620 kPa).

- Torque Settings:

- Side rod nuts (Ref. 77) should be tightened to 260 Nm (192 ft-lb).

- Nuts Ref. 43 should be torqued to 110 Nm (81 ft-lb).

- Nuts Ref. 44 should be torqued to 80 Nm (59 ft-lb).

- Side rods, if loose, should be tightened to 200 ft-lb (270 Nm).

- Wear Limits:

- Wear between piston, cylinder, and front cylinder liner should not exceed 0.2 mm (.008").

- Chuck wear should not exceed 2.5 mm (.100") at the worst point.

- Chuck insert wear should not exceed 1 mm (.040") oversize on the diameter.

- Thrust pad wear on the striking bar locating face should not exceed 2 mm (.080").

- Gear teeth wear: Replace if worn 50% or more.

- Piston Refacing: A maximum of 2mm can be removed during piston refacing operations.

- Rotation Speed: Adjustable to give a rotation speed of about 100 ~ 150 rpm, depending on hole size and rock hardness.

Usage Features

The S36 Rockdrill is designed for efficient and controlled drilling.

- Collaring: Requires a gentle, patient approach, gradually engaging rotation, water flushing, centralizer, and percussion. Multiple attempts may be needed for rough or angled surfaces.

- Drilling: Involves full water flushing, counter-clockwise rotation, and adjusting rotation speed for optimal penetration. The percussion lever should be fully forward.

- Feed Control: The amount of movement on the feed lever dictates the force behind the drilling bit. Proper feed adjustment is crucial to prevent overheating of drill string couplings (underfeeding) and hole misalignment (overfeeding).

- Adding Steel: After drilling a full length of steel, levers are moved to neutral, water flushing is turned off, and the centralizer clamps the coupling. The rotation lever is pulled clockwise to unthread, and the feed lever is pulled back to retract the feed, preventing thread binding. A new length of drill steel is then inserted and engaged.

- Rod Pulling: After drilling to the required length, all functions are disengaged. The hole is blown out with air to remove leftover flushing water. Percussion is engaged intermittently with feed movement to loosen drill string joints. The rockdrill and drill string are retracted, and couplings are clamped in the centralizer for unthreading. The rotation lever is used to unthread the drill steel from the coupling, with slight backward feed to prevent binding.

Maintenance Features

Regular maintenance is crucial for the S36 Rockdrill's optimal performance and longevity.

- Routine Servicing: Rockdrills should be serviced every 20 shifts or once a month, whichever is shorter, and a record kept for each machine. This includes external cleaning, stripping down, cleaning parts, inspection, replacement of worn components, rebuilding, and testing.

- Lubrication: Use only genuine rock drill lubricant from reputable suppliers, ensuring the correct grade for the application. The line lubricator bottle should be full at the start of each shift and topped up during extended use, checked and refilled twice per shift. Lubricators should be serviced regularly, cleaned, and feed jets checked for blockages. A fine mist of oil should be visible around the striking bar during operation, indicating adequate lubrication.

- Component Inspection:

- Backhead: Check water tube and seals, air stem and nut for excessive wear.

- Piston: Inspect striking face for flatness and smoothness; reface if dished, ensuring radius on spline end is restored.

- Cylinder and Front Cylinder: Check wear between piston, cylinder, and liner. Replace front cylinder liner if necessary to restore air cushion. Inspect feed nut threads.

- Valve Box Assembly: Clean and check for burrs. Ensure valve moves freely inside the box.

- Chuck and Bushing: Check for excessive wear on chuck, chuck insert, and thrust pad. Replace worn components. New inserts should be pressed, not hammered.

- Rotation Drive: Inspect gear teeth for wear or damage. Check needle roller bearings and shafts for wear and free movement.

- Dismantling and Assembly: Detailed procedures are provided for disassembling and reassembling the rockdrill, including specific instructions for the motor assembly, gear components, and various internal parts. Components should be cleaned and lubricated during assembly, and care taken to avoid jamming.

- Testing: After reassembly, rockdrills must be tested on a bench facility with 90 psi (620 kPa) air connection. This includes applying oil to the air inlet, installing the striking bar, clamping the drill, and slowly turning on air supply. Water testing is also required to check for leaks around the water inlet and into the body of the rockdrill.

- Troubleshooting: A comprehensive guide helps diagnose and resolve common issues such as the drill not starting, erratic operation, lack of power, slow drill speed, drill freezing, bogging, and piston chipping/breaking. Solutions range from checking for blockages and wear to adjusting lubrication and replacing damaged parts.

- Safety: Emphasizes the importance of reading the manual, proper training, using qualified service technicians, wearing personal protective equipment (hearing protection, safety glasses), isolating energy sources, using safe lifting procedures, and complying with health and safety regulations. Unauthorized alterations or use of non-Boart Longyear parts will void the warranty.