139 S130 Operation & Maintenance Manual

HYDRAULIC / HYDROSTATIC SYSTEM (CONT’D)

Removing And Replacing Hydraulic / Hydrostatic

Filter

For the correct service interval (See SERVICE

SCHEDULE on Page 111.)

Raise the operator cab. (See Raising on Page 120.)

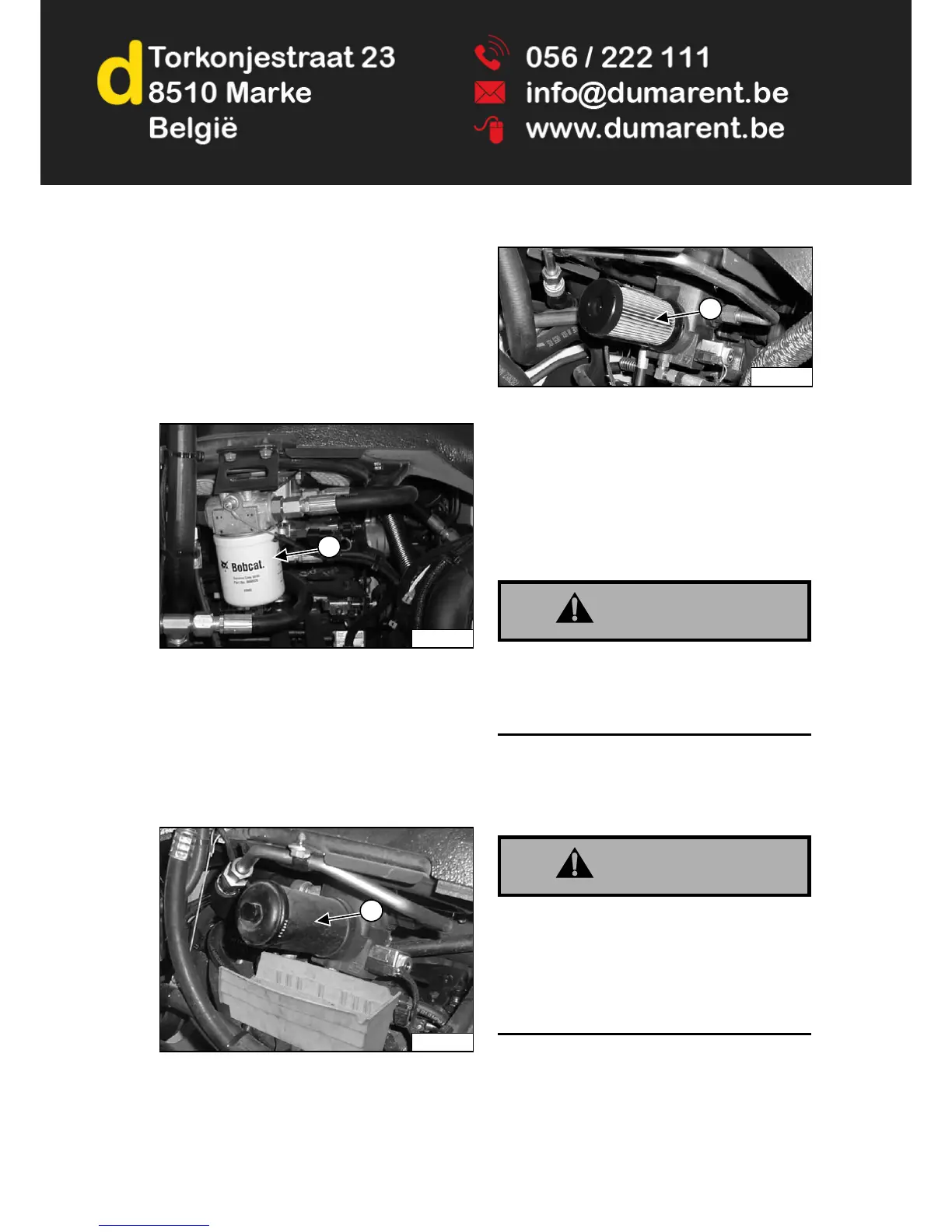

Earlier Models

Figure 203

Remove the filter (Item 1) [Figure 208].

Clean the surface of the filter housing where the filter seal

contacts the housing.

Put clean oil on the seal of the new filter. Install and hand

tighten the new filter.

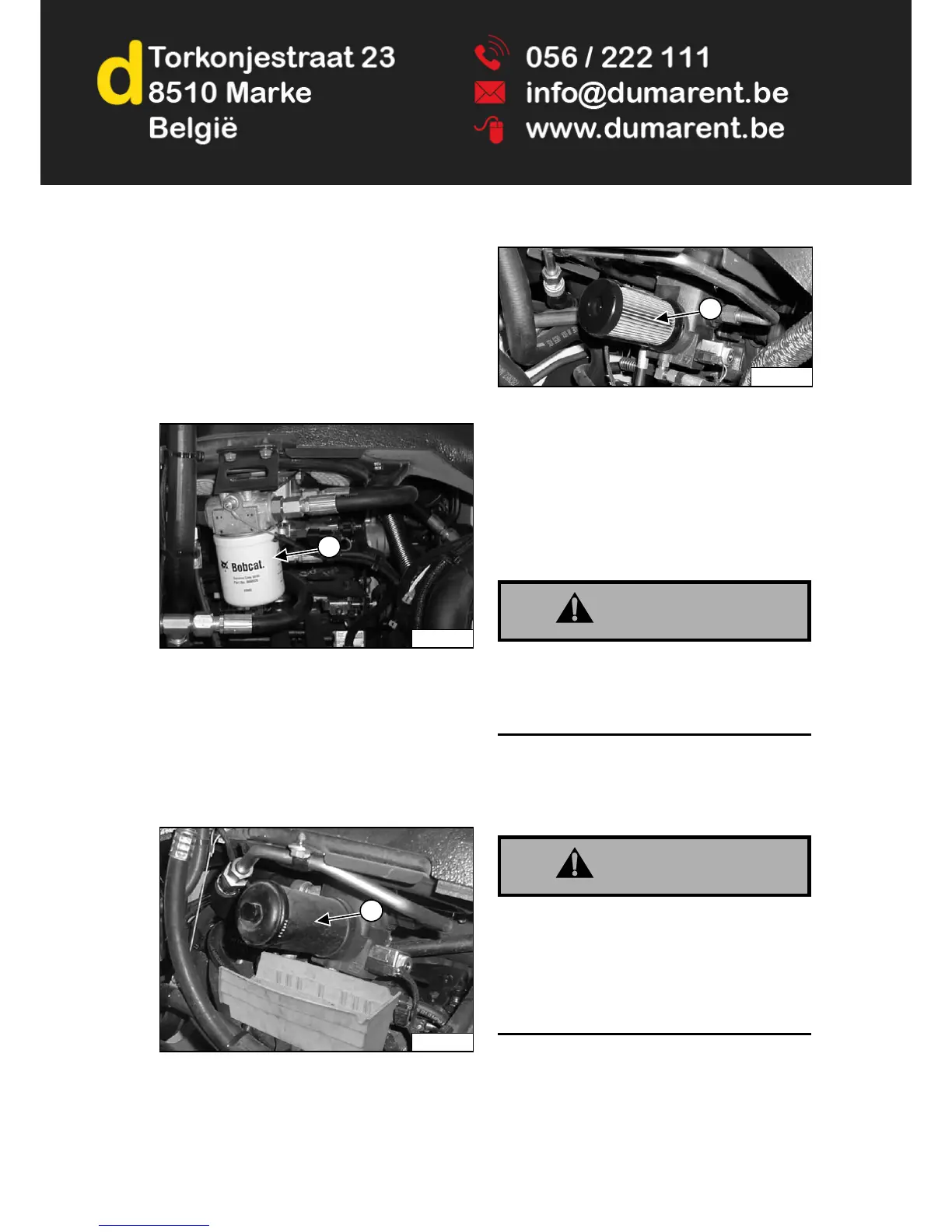

Later Models

Figure 204

Place a suitable container below the filter housing and

remove the filter housing (Item 1) [Figure 204].

Recycle or dispose of used fluid in an environmentally

safe manner.

Figure 205

Remove and discard the filter element (Item 1) [Figure

205].

Clean the surface of the filter housing and the filter base

where they contact the filter element seal.

Put clean oil on the seal of the new filter element. Install

the element on the filter base. Install and hand tighten the

filter housing to 47 - 54 N•m (35 - 40 ft-lb) torque.

All Models

AVOID INJURY OR DEATH

Always clean up spilled fuel or oil. Keep heat, flames,

sparks or lighted tobacco away from fuel and oil.

Failure to use care around combustibles can cause

explosion or fire.

W-2103-0508

Lower the operator cab. (See Lowering on Page 121.)

Start the engine and operate the loader hydraulic

controls.

AVOID INJURY OR DEATH

Diesel fuel or hydraulic fluid under pressure can

penetrate skin or eyes, causing serious injury or

death. Fluid leaks under pressure may not be visible.

Use a piece of cardboard or wood to find leaks. Do

not use your bare hand. Wear safety goggles. If fluid

enters skin or eyes, get immediate medical attention

from a doctor familiar with this injury.

W-2072-EN-0909

Stop the engine and check for leaks at the filter.

Check the fluid level in the reservoir and add as needed.

(See Checking And Adding Fluid on Page 137.)

Loading...

Loading...