131 S650 Operation & Maintenance Manual

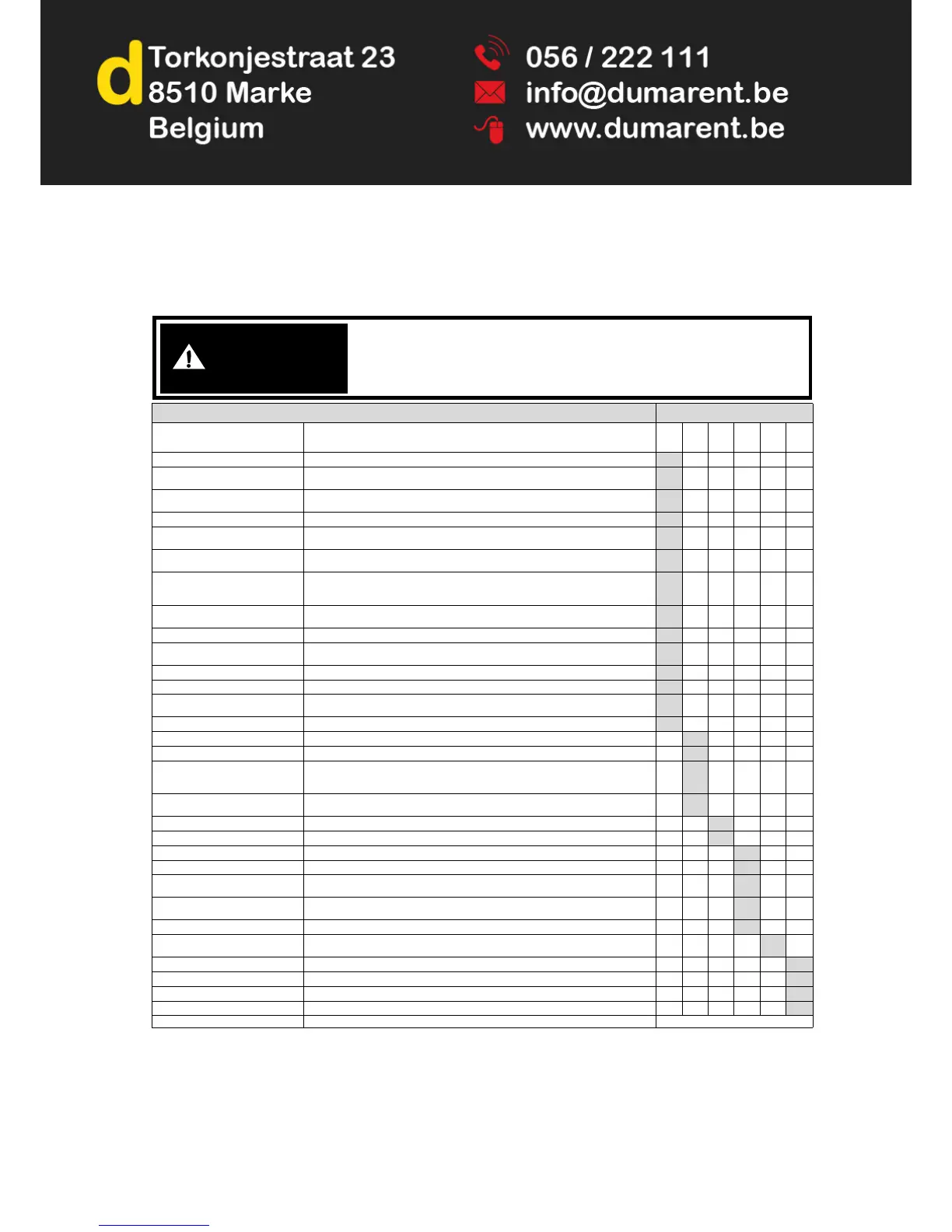

SERVICE SCHEDULE

Chart

Maintenance work must be done at regular intervals. Failure to do so will result in excessive wear and early failures. The

service schedule is a guide for correct maintenance of the Bobcat loader.

[1] Check every 8 - 10 hours for the first 24 hours, then at 50 hour intervals.

[2] Perform at first 50 hours, then as scheduled.

[3] Change oil and filter every 100 hours when operating under severe conditions.

[4] Perform at first 500 hours, then as scheduled.

[5] Or every 12 months.

NOTE: The Inspection Checkbook can be ordered for you by your local dealer. Part number 4420300.

SERVICE SCHEDULE HOURS

ITEM SERVICE REQUIRED

8-10 50 100

[5]

250

[5]

500

[5]

1000

Engine Oil Check the oil level and add as needed. Do not overfill.

Engine Air Filter and Air System Check display panel. Service only when required. Check for leaks and

damaged components.

Engine Cooling System Clean debris from oil cooler, radiator and grille. Check coolant level COLD and

add premixed coolant as needed.

Fuel Filter Remove the trapped water.

Lift Arms, Lift Links, Cylinders,

Bob-Tach, Pivot Pins, Wedges

Lubricate with multipurpose lithium based grease.

Tyres Check for damaged tyres and correct air pressure. Inflate to MAXIMUM

pressure shown on the sidewall of the tyre.

Seat Bar, Control Interlocks, Seat

Belt, Seat Belt Retractors

Check the condition of seat belt. Clean or replace seat belt retractors as

needed. Check the seat bar and control interlocks for correct operation. Clean

dirt and debris from moving parts.

Bobcat Interlock Control Systems

(BICS™)

Check for correct function. Lift and Tilt functions MUST NOT operate with seat

bar raised. See details in this Manual.

Front Horn Check for proper function.

Safety Signs and Safety Treads Check for damaged signs (decals) and safety treads. Replace any signs or

safety treads that are damaged or worn.

Operator Cab Check the fastening bolts, washers and nuts. Check the condition of the cab.

Indicators and Lights Check for correct operation of all indicators and lights.

Heater and A/C Filters

(If Equipped)

Clean or replace filters as needed.

Hydraulic Fluid Check fluid level and add as needed.

Hydraulic Hoses and Tubelines Check for damage and leaks. Repair or replace as needed.

Final Drive Trans. (Chaincase), Check fluid level and add as needed.

Parking Brake, Foot Pedals,

Hand Controls and Steering

Levers or Joysticks

Check for correct operation. Repair or adjust as needed.

Wheel Nuts Check for loose wheel nuts and tighten to correct torque. (See TYRE

MAINTENANCE in this manual.)

[1]

Spark Arrester Muffler Clean the spark chamber.

Battery Check cables, connections and electrolyte level. Add distilled water as needed.

Fuel Filter Replace filter element.

Engine / Hydro. Drive Belt Check for wear or damage. Check idler arm stop.

[2]

Drive Belts (Alternator, air

conditioning, water pump)

Check condition. Replace as needed.

Bobcat Interlock Control System

(BICS™)

Check the function of the lift arm bypass control.

Engine Oil and Filter Replace oil and filter.

[2] [3]

Hydraulic Charge Filter,

Hydraulic Reservoir Breather

Replace the charge filter and the reservoir breather.

Hydraulic / Hydrostatic Filter Replace the hydraulic / hydrostatic filter.

Final Drive Trans. (Chaincase) Replace the fluid.

Hydraulic Reservoir Replace the fluid.

Engine Valves Adjust the engine valves.

[4]

Coolant Replace the coolant Every 2 years

WARNING

Instructions are necessary before operating or servicing machine. Read and

understand the Operation & Maintenance Manual, Operator’s Handbook and

signs (decals) on machine. Follow warnings and instructions in the manuals

when making repairs, adjustments or servicing. Check for correct function

after adjustments, repairs or service. Untrained operators and failure to follow

instructions can cause injury or death.

W-2003-0807

Loading...

Loading...