136 S650 Operation & Maintenance Manual

SEAT BELT

Inspection And Maintenance

WARNING

Failure to properly inspect and maintain the seat belt

can cause lack of operator restraint resulting in

serious injury or death.

W-2466-0703

Check the seat belt daily for correct function.

Inspect the seat belt system thoroughly at least once

each year or more often if the machine is exposed to

severe environmental conditions or applications.

Any seat belt system that shows cuts, fraying, extreme or

unusual wear, significant discolourations due to

ultraviolet UV exposure, dusty / dirty conditions, abrasion

to the seat belt webbing, or damage to the buckle, latch

plate, retractor (if equipped), hardware or any other

obvious problem should be replaced immediately.

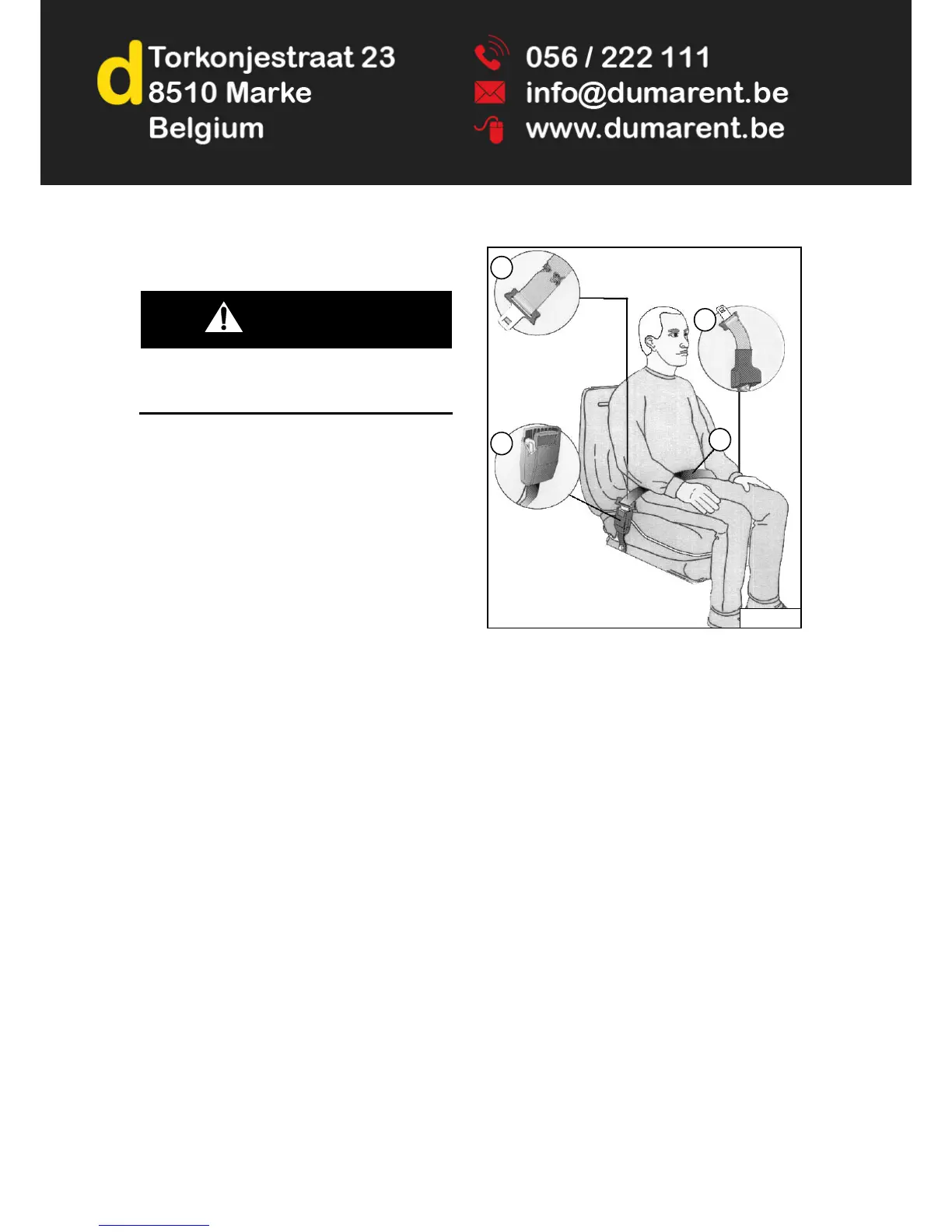

The items below are referenced in [Figure 178].

1. Check the webbing. If the system is equipped with a

retractor, pull the webbing completely out and inspect

the full length of the webbing. Look for cuts, wear,

fraying, dirt and stiffness.

2. Check the buckle and latch for correct operation.

Make sure latch plate is not excessively worn,

deformed or buckle is not damaged or casing broken.

3. Check the retractor web storage device (if equipped)

by extending webbing to determine if it looks correct

and that it spools out and retracts webbing correctly.

4. Check webbing in areas exposed to ultraviolet (UV)

rays from the sun or extreme dust or dirt. If the original

colour of the webbing in these areas is extremely

faded and / or the webbing is packed with dirt, the

webbing strength may have deteriorated.

See your Bobcat dealer for seat belt system replacement

parts for your machine.

Figure 178

B-22283

1

2

3

4

Loading...

Loading...