Your VAVD Controller has been designed with the highest quality materials and to the strictest production

tolerances. Unlike common hospital suction regulators, the VAVD controller has precision low suction output

and redundant safety features to limit excess negative pressure and positive pressure. Given the critical nature

of the clinical interventions for which the VAVD Controller is employed, and the inherent risk involved in applying

unregulated suction during these procedures, only factory service and calibration may be performed on this unit.

Factory calibration is recommended - -

• Any time fluid has entered the VAVD Controller.

• Any time there is physical damage noted to VAVD Controller.

• Any time the VAVD Controller fails a pre-use test.

• A minimum of every 24 months.

WAGD Tube Assembly (Model 3947) - -

It is recommended to replace the WAGD Tube Assembly every (3) three months or sooner if it has any sign of

being damaged or visibly contaminated. Additional WAGD Tube Assemblies (Model 3947) are available for

purchase.

Please call Customer Service at 800-642-4945 to obtain an RMA prior to return or to order additional WAGD

Tube Assemblies (Model 3947). Once the unit has been received you will be contacted with an estimate of any

service charges. Units will be serviced within five days of receipt of charge authorization.

After patient use, wipe all exterior surfaces of the VAVD Controller with an appropriate surface

disinfectant. Appropriate disinfectants are:

• 3M Quat®

• Cavacide®

Your VAVD regulator has been designed for years of trouble-free service. Should you experience difficulty that

is not the result of damage to the instrument, the most likely cause is aspiration of dirt and/or fluids into the

Regulator.

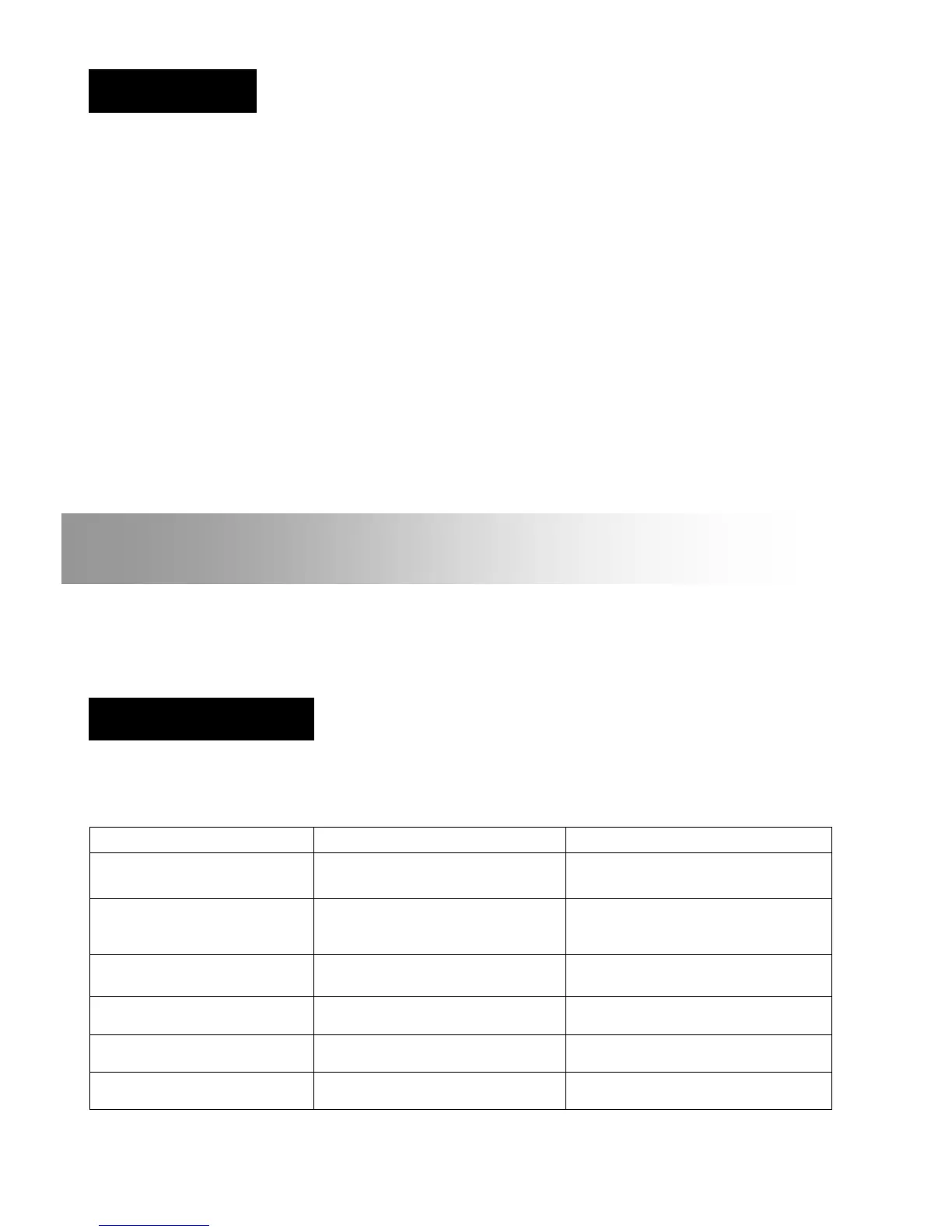

Symptom Probable Cause Solution

Instrument fails to provide suction at

the patient port.

The supply or patient fittings are clogged,

or the incoming suction tubing is collapsed

Replace or clean the fittings. Replace the

incoming suction line.

Gauge doesn't respond to changes in

suction (via control valve or

adjustment knob)

Gauge diaphragm is improperly sealed on

the gauge piston and/or view tube

Reference Boehringer Tech Bulletin

3700.044.

Gauge piston is discolored.

Material has entered the inside of the

device.

Instrument is contaminated. Please return to

the factory for service.

Instrument will not shut off or exhibits

high spike.

Dried fluids may have cut the quad ring

seal.

Please return to the factory for service.

Instrument fails to regulate suction

Piston/Stem surface is binding with foreign

matter

Please return to the factory for service.

Audible sound coming from safety

port on safety interrupter

Material has entered the inside of the

device.

Instrument is contaminated. Please return to

the factory for service.

3930.003 Rev C P/N 34031 8 of 9

Released July 2014 User Manual VAVD Controller

Loading...

Loading...