Installation

The V600 has been designed to remove and filter fume

containing potentially hazardous particulate and gases

generated during manufacturing processes. Such hazardous

substances are captured within a multistage filtration

system after which the cleaned air is returned to the

workplace.

Fume Capture Methods

The fume is normally captured by 1 of 3 methods.

• Flexible arm/ Nozzle

• Enclosures

• Cabinets

General Guidelines for a successful installation

• Keep duct run length to a minimum

• Avoid sharp bends / turns in the ductwork

• Avoid multiple bends / turns in the ductwork

• Use a larger diameter duct where able

• Position the capture device as close as possible to

the marking point. (if used on high speed lines,

position the capture device slightly downstream)

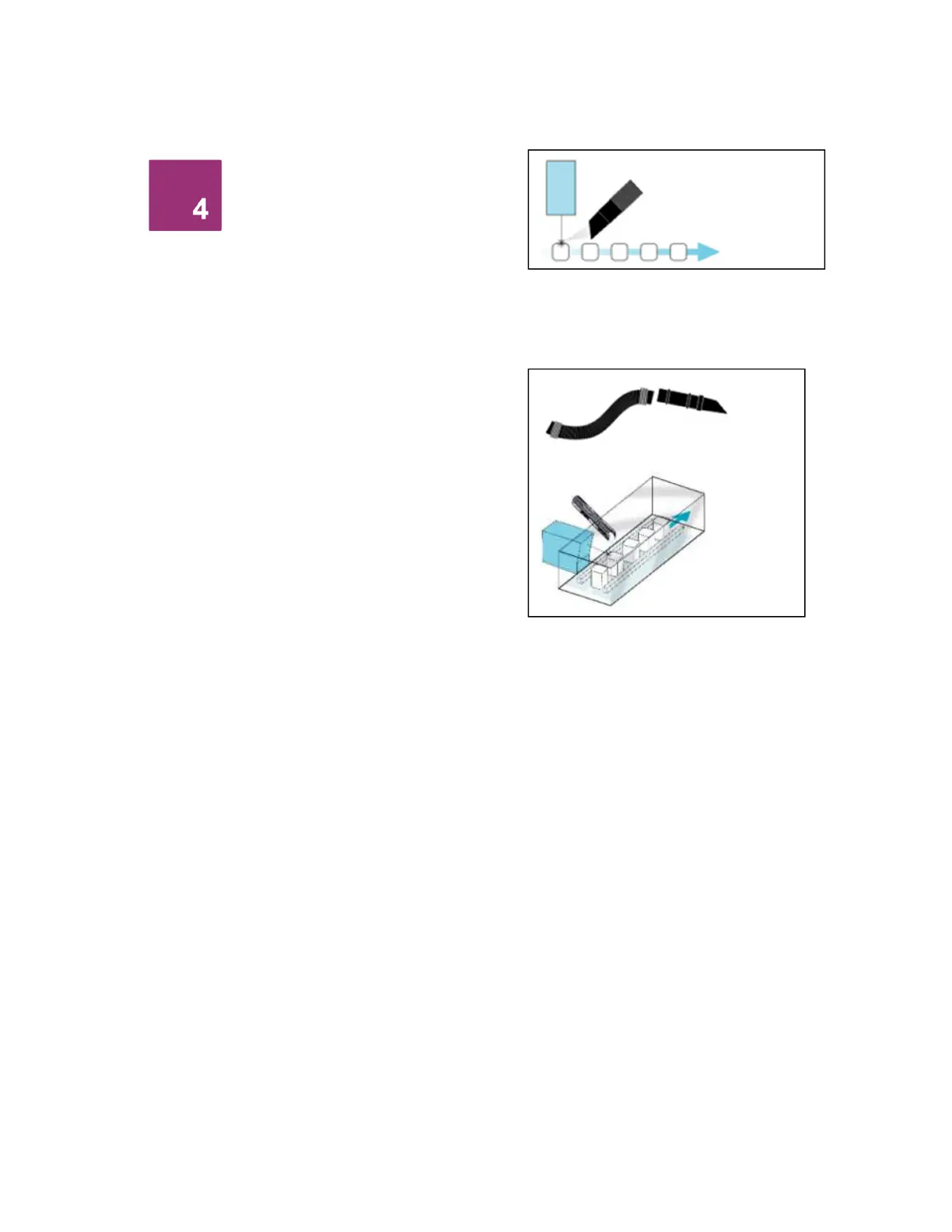

Flexible Arm & Nozzle Extraction

The stay put arm should be mounted as close as possible to

the marking point using the horseshoe clips. Unscrew the

push fit connector from the other side of the flexible hose.

Cut the flexible hose to suit the distance back to the

extractor connection and push onto the extractor inlet.

Purge air should be kept to a minimum, where possible, to

prevent the fume being blown away from the nozzle.

High speed bottling lines may need bigger scoops or nozzles

both sides of the bottles because of the turbulence caused

by the speed of the bottles.

Moving products

For applications where the product to be marked is moving

past the stationary laser head the capture nozzle should be

positioned as close as possible to the marking area on the

side the product is moving towards.

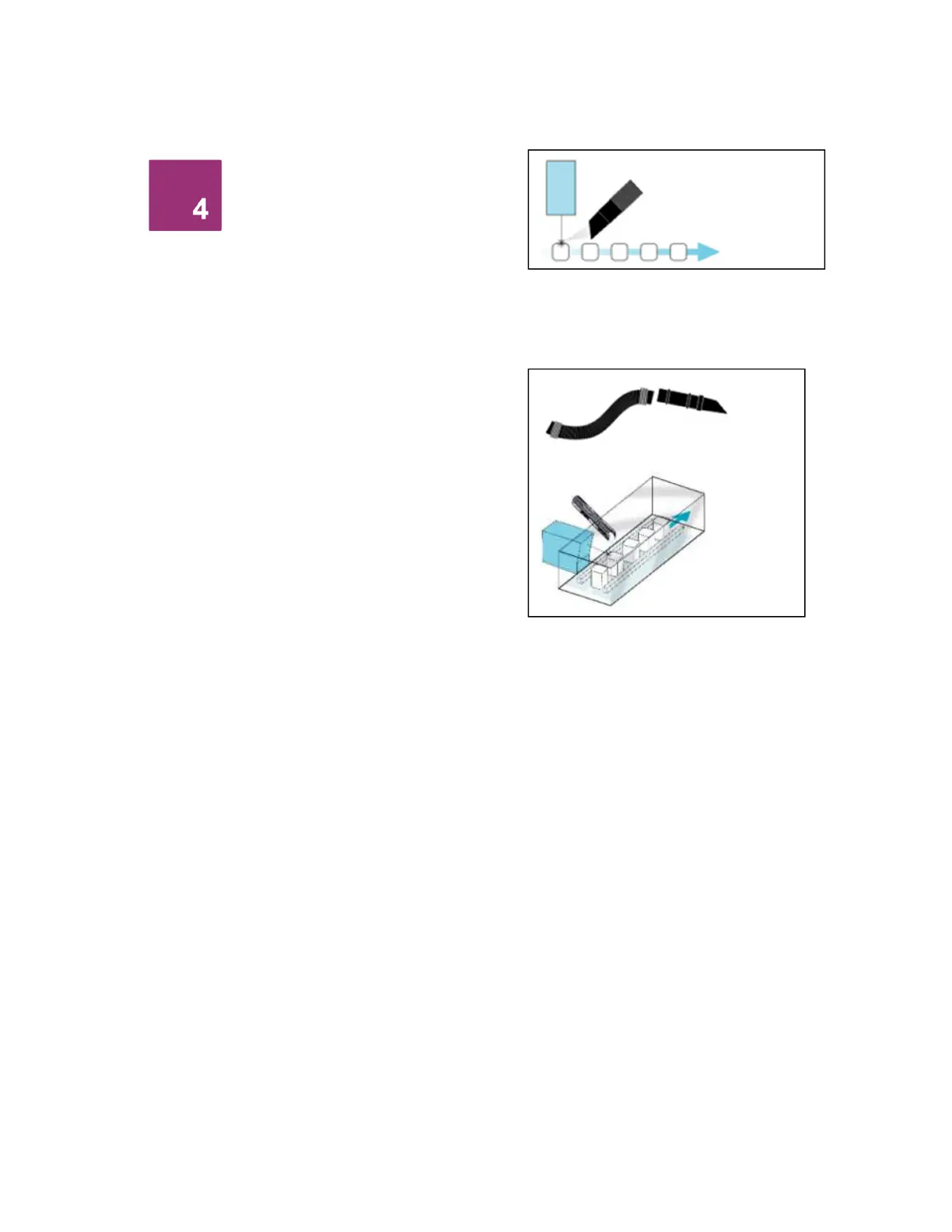

Enclosures

The extraction hose and nozzle can be attached to the

enclosure surrounding the marking zone provided that the

extraction point is within 50-75mm of the marking point.

Loading...

Loading...