Example:

Also check that high temperatures are not being generated at the gearbox bearings.

Limit temperature exceeded Limit temperature NOT exceeded

For installations in zones 21 and 22, the user must schedule and implement a regular cleaning

programme for all surfaces and recesses to avoid dust build-ups of more than 5 mm in depth.

Every 100 hours of operation or every 2 weeks:

• Measure the surface temperature at the coupling between the gearbox and motor, and at the points most

shielded from the forced ventilation provided by the motor’s fan. Maximum surface temperature measured

at these points must not exceed ambient temperature by more than 75 K (ΔT) (90 K in the case of the

W 110 gearbox), and this temperature differential must not have been exceeded in service. Check the

condition of the heat sensor installed previously.

Every 1000 hours of operation or every 6 months:

• Check the oil level according to the tables provided in the “LUBRICATION” section of this manual and

according to the gure below.

• Check that there are no signs of lubricant leaks near the gearbox.

• If any anomalies are found, identify their cause, make the necessary repairs, and top up the

lubricant level before putting the gearbox back into service.

Every 3000 hours of operation:

• On gearboxes with reaction arms, check that the polymer bushes are not aged or damaged. If the bushes

show any sign of fatigue or damage, replace them with original spare parts.

Every 5000 hours of operation:

• Change the synthetic oil and bearing grease if the gearbox is not lubricated for life.

• Replace all externally accessible seal rings unless this has already been done as a result of problems

occurring before the scheduled maintenance was due.

Every 5000 hours of operation at rated torque

(The minimum overhaul interval specied here may increase considerably, depending on actual service

cycles. See the table below).

• General overhaul of the gearbox, if not performed earlier as a result of malfunctioning (Overhaul consists

of the replacement of all bearings and/or other mechanical components showing signs of wear that might

compromise the functioning of the gearbox).

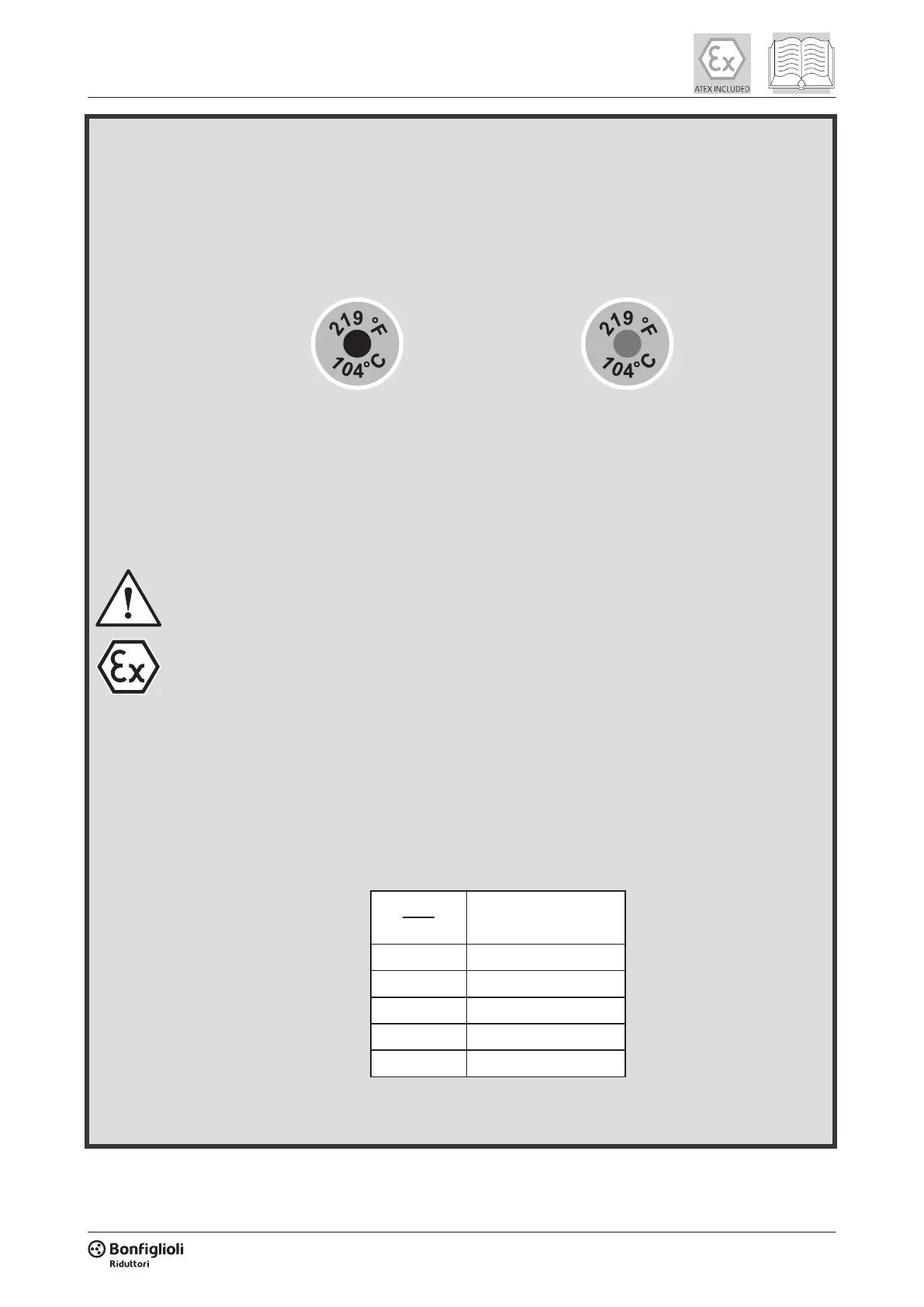

M

n2

= Rated torque at output shaft

M

n2

= Required torque at output shaft

(tab 9)

M

n2

Interval (hours)

M

r2

1.0 5000

1.25 10000

1.5 17000

1.75 27000

2.0 40000

57 / 64

IOM Manual VF-W_ATEXgb - Translation of original instructions in Italian - Rev 03_0 - 30/09/16

Loading...

Loading...