19

Fluid Secon Seal Replacement Instrucons

WARNING! Always wear protecve eye wear while servicing the pump. Be sure to follow the Pressure Relief Procedure when shung the unit down for any

purpose, including servicing or adjusng. Aer performing the Pressure Relief Procedure, be sure to unplug the unit before servicing or adjusng. Area must

be free of solvents and paint fumes.

Disassembly of the Fluid Secon

1. Remove the sucon set.

2. Remove the front cover and the four screws that secure it using a T20 Torx head driver.

3. using a T20 Torx head driver.

4. Remove the yoke screw and washer that secures the dowel pin. The dowel pin connects the yoke to the piston.

5. a). For this machine, rotate the pump sha so the piston is in the top dead center posion. This can be done by pushing on the yoke. This is required to

disassemble all the parts.

b). For other models, inspect the yoke assembly and piston. In order to remove all the necessary parts, the piston must not be in the boom dead center po-

sion. If the piston is at the boom of the stroke, install the front cover and screws, turn the pump on briey to index the piston, unplug the unit, and repeat

step 2.

6. Unscrew and remove the inlet valve assembly .

7. Remove the piston assembly by pushing down on the piston near the yoke.

8. Unscrew and remove the top nut using and adjustable wrench.

9. Remove the worn seals using a at head screwdriver or punch. Remove the top seal from the top and the boom seal from the boom by pressing against

the side of the seal and popping it out. Be sure not to scratch the housing where the seals are located.

10. Clean the area where the new seals are to be installed.

Assembly of the Fluid Secon

1. Lubricate the new top seal with Separang Oil or light household oil and by hand place the seal (cup side of seal down) into the top port of the housing.

2. Place a small amount of an-seize on the threads of the top nut. Place the top nut into the top of the housing and ghten with an adjustable wrench. This

will drive the top seal into the correct posion.

3. Turn the pump upside down. Lubricate the seal on the piston/seal assembly similar to the top seal. Place the piston/seal assembly into the boom of the

housing. Insert the plasc inseron tool and thread into posion to properly seat the piston/seal. Thread fully unl ght. Remove the inseron tool.

4. Install the new O-ring on the inlet valve assembly, lubricate with Separang Oil, thread into the boom.(inlet) of the housing, and ghten with an adjustable

wrench. This will drive the boom seal into the correct posion.

5. Align the piston with the yoke. Be careful not to damage the piston.

6. Apply any type of household grease to the piston and yoke area to prolong life. Apply to the holes in the yoke where the dowel is inserted.

7. Install the dowel pin to connect the yoke to the piston. The piston may have to be moved up or down to do this.

8. Install the yoke screw and washer to secure the dowel pin.

9. Turn pump right side up and apply a few drops of Separang Oil or light household oil between the top nut and piston. This will prolong the seal life.

10. Install front cover and four (4) screws.

11. Replace inlet valve. Install the sucon set.

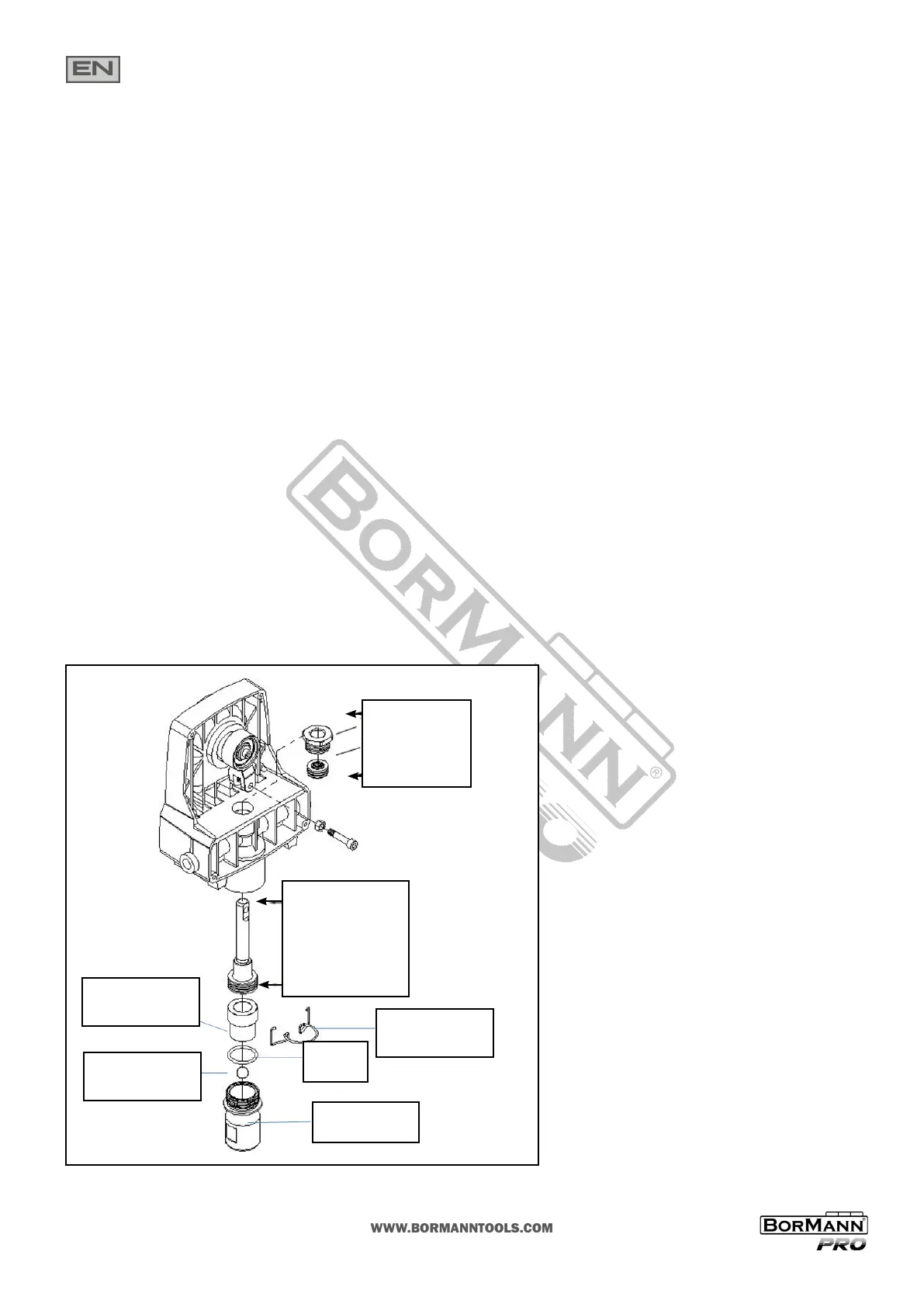

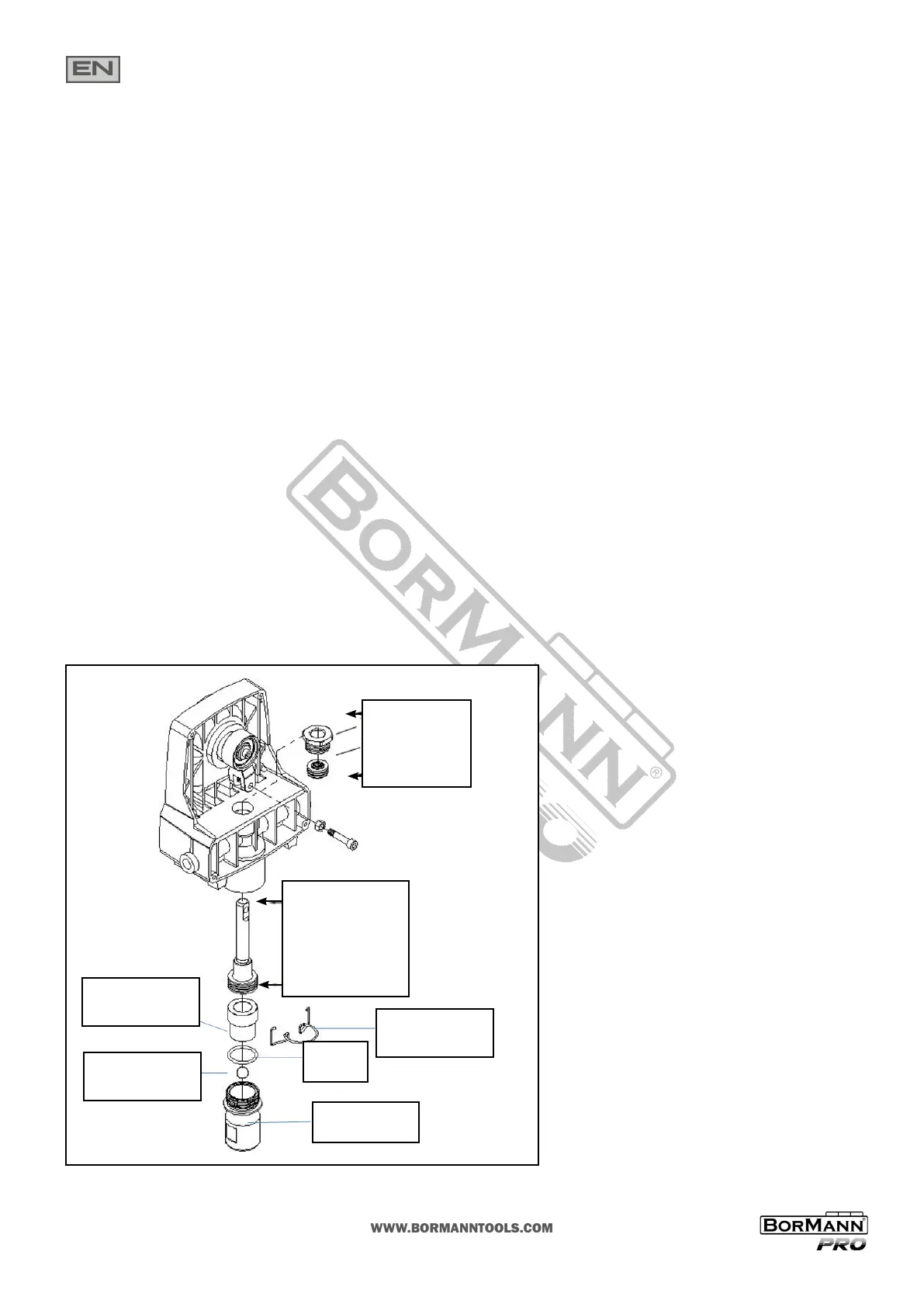

Locang sleeve

Steel ball

Lathe dog

O-ring

Valve body

Piston/seal assembly

NOTE- DO NOT

aempt to remove the

seals from the piston

Top nut

Top seal

(cup down)

Loading...

Loading...