-8-

Operating Instructions

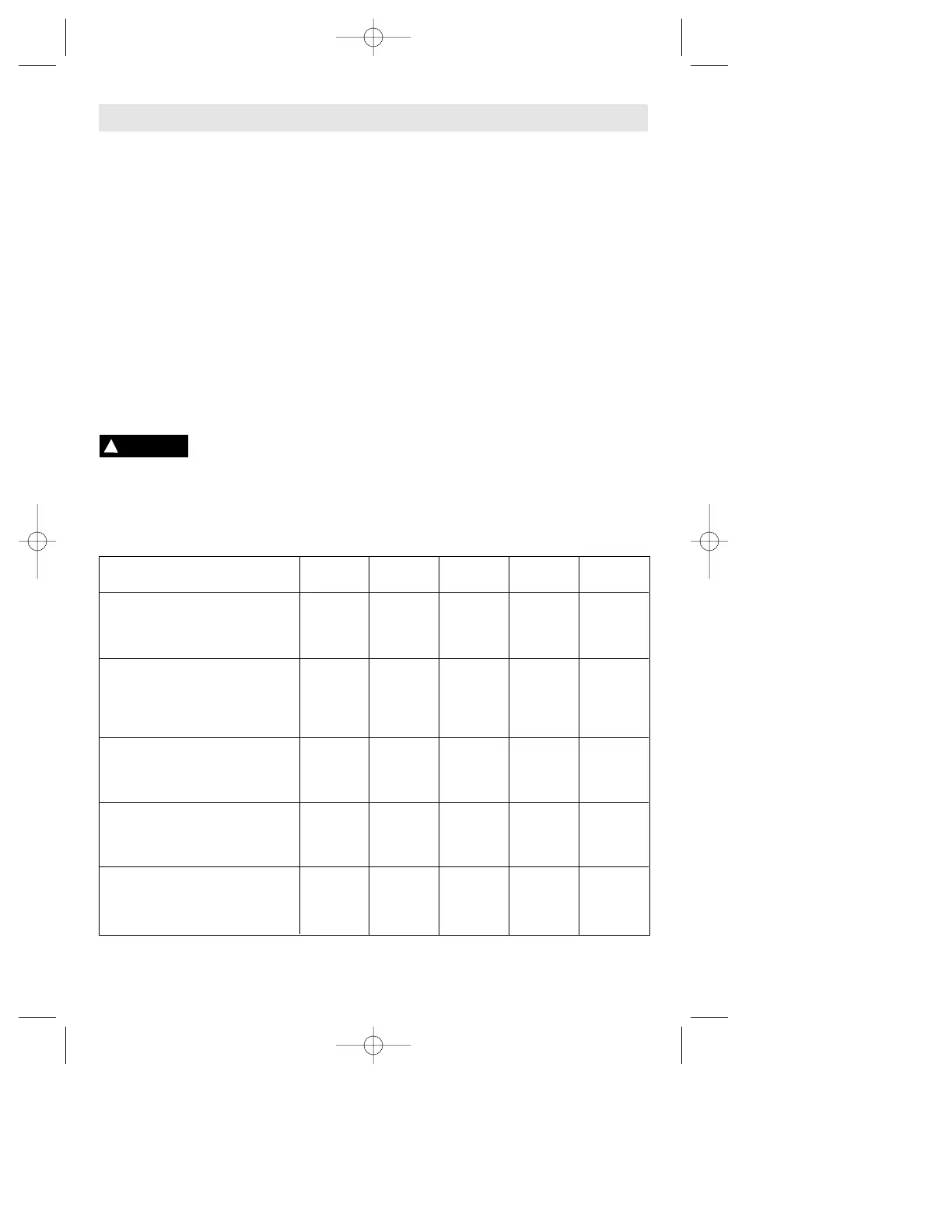

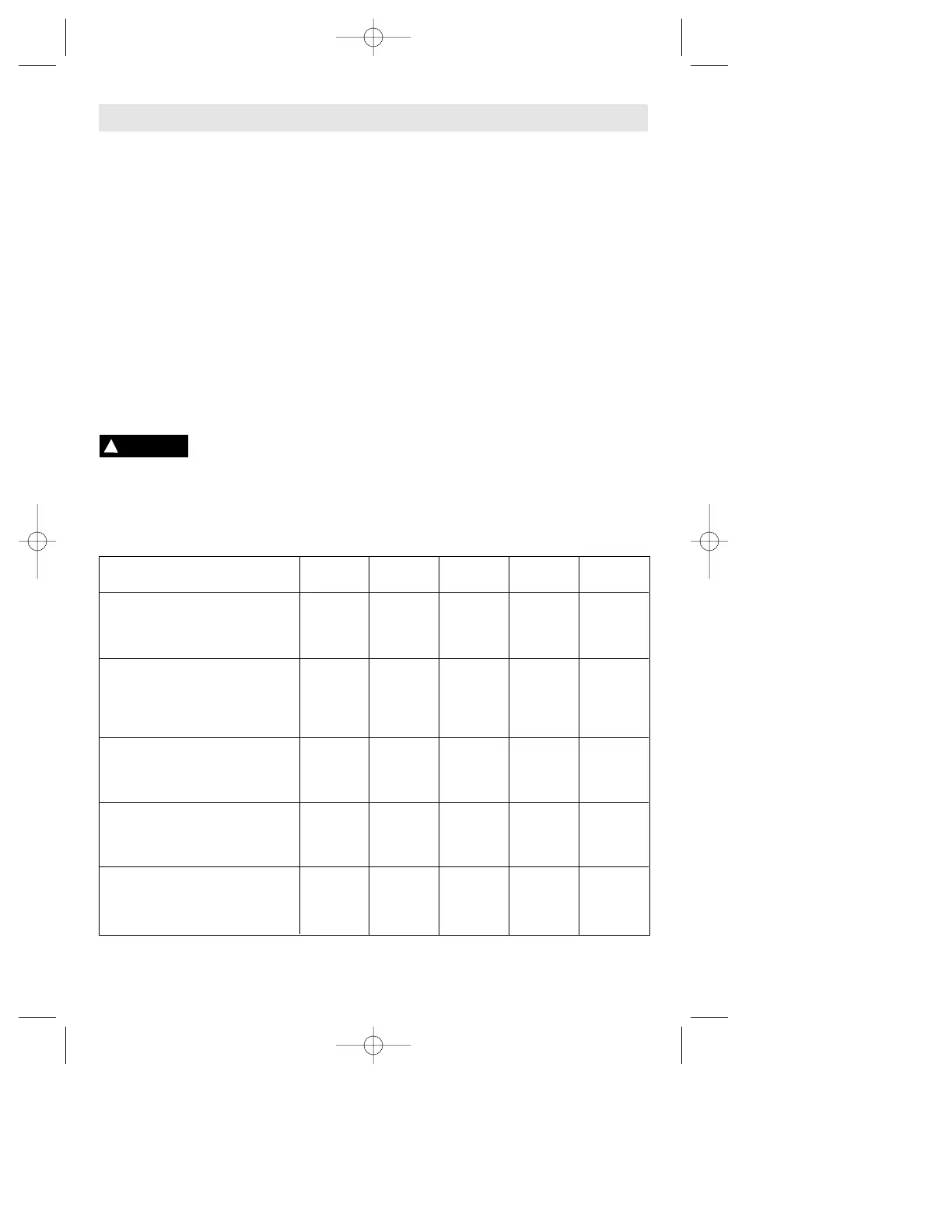

Rough Fine Drive Switch Backing

Material sanding sanding position setting pad

Woods: Grit size Grit size

Softwoods 60 240 b 1-4 soft

Hardwoods 60 180/240 a/b 3 / 6 med

Veneers 240 400 b 1-2 soft

Metals:

Steel 80/180 600 a 3-6 med/hard

Stainless 120 240 a 4-6 med

Aluminum 80 240/400 a/b 1-3 med

Rust spots 24 120 a 4-6 soft

Synthetic paint:

Sanding 180 400 b 3 med

Scratches 120 220 a/b 3-4 hard

Stripping 24/40 80/120 a 5-6 med

Acrylic paint:

Sanding 180 400/1200 b 3-4 med

Scratches 120 224 a/b 2-4 hard

Stripping 60 80/120 a 3-6 med

Plastics

PC/polystyrene 120 240 a/b 1-3 soft/med

Thermoplastics 60 180 a/b 1-2 med

Glass fiber reinforsed plastics 80/120 20/320 a 1-3 med/hard

SLIDE ON-OFF SWITCH WITH LOCK

The tool is switched “ON” by the switch

button located at the side of the motor

housing. The switch can be locked in the

“ON” position, a convenience for long

grinding operations.

TO TURN THE TOOL “ON” without locking

it, slide the switch button forward by

applying pressure ONLY at the REAR portion

of the button. When pressure is released the

switch button will snap to “OFF” position.

TO LOCK THE SWITCH “ON”, slide the

switch button forward and press “IN” the

FRONT portion.

TO UNLOCK THE SWITCH, simply press

and release the REAR portion of the button.

Switch is spring loaded and will snap back

automatically.

Hold the tool with both

hands while starting the tool,

since torque from the motor can cause the

tool to twist.

Start the tool before applying to work and let

the tool come to full speed before contacting

the workpiece. Lift the tool from the work

before releasing the switch. DO NOT turn the

switch “ON” and “OFF” while the tool is

under load; this will greatly decrease the

switch life.

ELECTRONIC FEEDBACK CIRCUITRY (EFC)

The internal electronic feedback system

provides a "soft start", which will reduce the

stresses that occur from a high torque start.

The system also helps to keep the no load

speed virtually constant between no-load

and load conditions.

VARIABLE SPEED WITH DIAL SETTING

Your sander is also equipped with a variable

speed dial. The sander's orbital pad speed

can be preset from zero to maximum

nameplate OPM by rotating the dial in the

housing. The dial may be set on or between

any of six positions (1=low through 6=high).

The following table may be used as a general

guide for abrasive and backing pad selection,

but the best results will be obtained by

sanding a test sample of the workpiece first.

!

WARNING

Loading...

Loading...