English | 15

Bosch Power Tools 1 609 92A 0BR | (14.10.13)

11 Nozzle

12 Nozzle seal

13 Air hose

14 SDS connector

15 Base unit

16 Control knob for On/Off and air-flow control

17 Set-down port for spray gun

18 Hose connection (base unit)

19 Handle

20 Accessory compartment

21 Air filter cover

22 Measuring cup

*Accessories shown or described are not part of the standard de-

livery scope of the product. A complete overview of accessories

can be found in our accessories program.

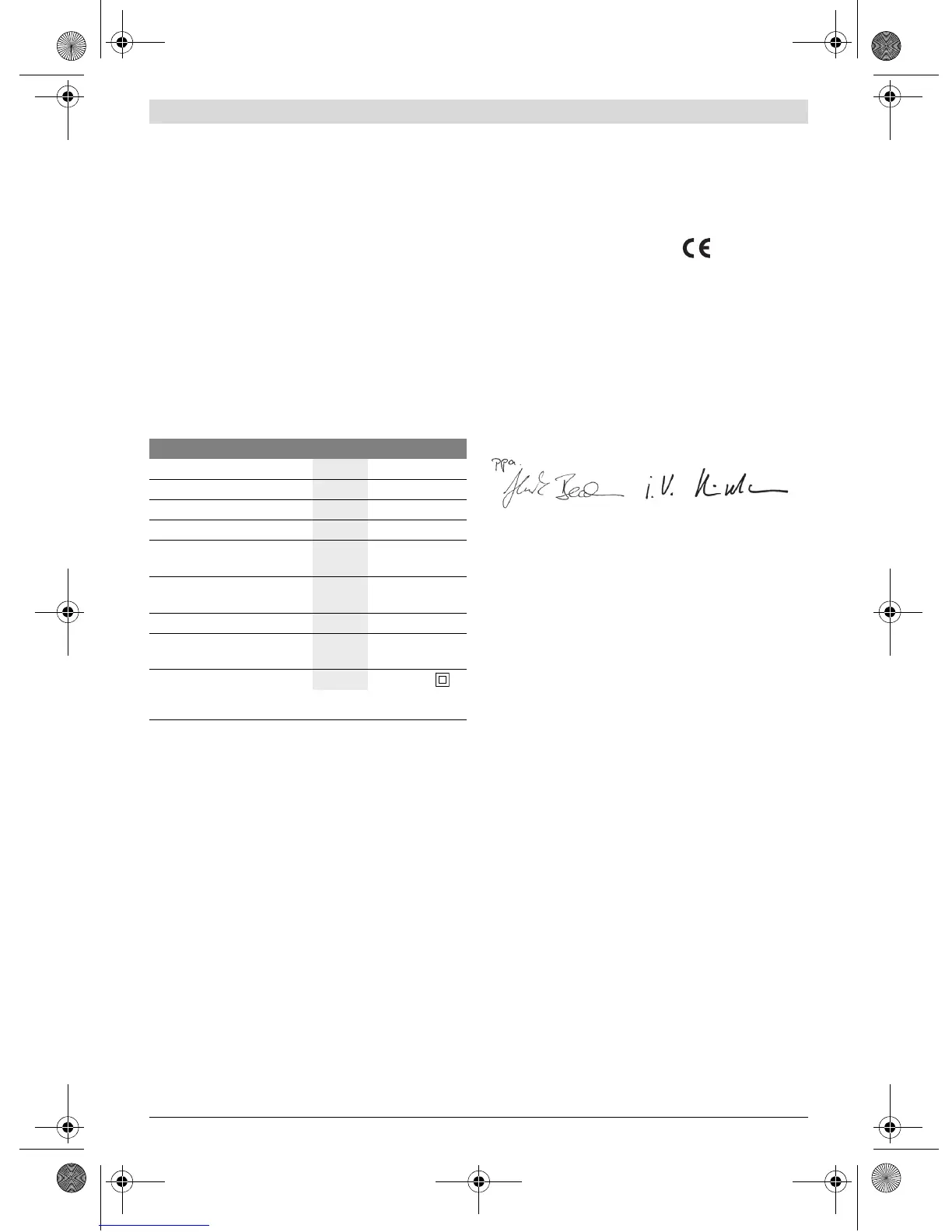

Technical Data

Noise/Vibration Information

Measured sound values determined according to EN 60745

and EN 50580.

Typically the A-weighted sound pressure level of the product

is 74 dB(A). Uncertainty K=3 dB.

The noise level when working can exceed 80 dB(A).

Wear hearing protection!

Vibration total values a

h

(triax vector sum) and uncertainty K

determined according to EN 60745:

a

h

< 2,5m/s

2

, K= 1,5 m/s

2

.

The vibration level given in this information sheet has been

measured in accordance with a standardised test given in

EN 60745 and may be used to compare one tool with another.

It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main ap-

plications of the tool. However if the tool is used for different

applications, with different accessories or insertion tools or is

poorly maintained, the vibration emission may differ. This may

significantly increase the exposure level over the total working

period.

An estimation of the level of exposure to vibration should also

take into account the times when the tool is switched off or

when it is running but not actually doing the job. This may signif-

icantly reduce the exposure level over the total working period.

Identify additional safety measures to protect the operator

from the effects of vibration such as: maintain the tool and the

accessories, keep the hands warm, organisation of work pat-

terns.

Declaration of Conformity

We declare under our sole responsibility that the product de-

scribed under “Technical data” is in conformity with the fol-

lowing standards or standardization documents: EN 60335

and the directives 2011/65/EU, 2006/42/EC,

2004/108/EC including their amendments.

Technical file (2006/42/EC) at:

Robert Bosch GmbH, PT/ETM9,

D-70745 Leinfelden-Echterdingen

Robert Bosch GmbH, Power Tools Division

D-70745 Leinfelden-Echterdingen

Leinfelden, 18.10.2013

Assembly

Before any work on the machine itself, pull the mains

plug.

Connecting the Air Hose (see figures A1 – A2)

– Take the air hose 13 out of the accessory compartment 20.

– Remove the protective caps from both ends of the air hose.

Connecting to the spray gun:

– Firmly insert an SDS connector 14 of the air hose in align-

ment with the arrow mark into the hose port of the spray

gun 6.

– Turn the SDS connector until the lock engages.

Connecting the base unit:

– Firmly insert the second SDS connector of the air hose in

alignment with the arrow mark into the port of the base

unit 18.

– Turn the SDS connector until the lock engages.

Note: After use, reattach the protective hose caps to the hose

ends.

Operation

Preparing for Operation

Spraying on the sides of water bodies (lakes, rivers,

etc.) or neighbouring surfaces in the direct catchment

area is not permitted.

When purchasing paint, varnish and spray material, pay at-

tention to their environmental compatibility.

Fine-spray System PFS 105 E

Article number

3 603 B06 2..

Rated power input

W 350

Spraying capacity

g/min 150

Atomising output

W 0 –105

Required time for application

of paint on 5 m

2

min 6

Container capacity for spray

material

ml 800

Length of air hose

m3,4

Weight according to

EPTA-Procedure 01/2003 kg 4,9

Protection class

/II

The values given are valid for a nominal voltage [U] of 230 V. For differ-

ent voltages and models for specific countries, these values can vary.

Henk Becker

Executive Vice President

Engineering

Helmut Heinzelmann

Head of Product Certification

PT/ETM9

OBJ_BUCH-420-003.book Page 15 Monday, October 14, 2013 2:59 PM

Loading...

Loading...