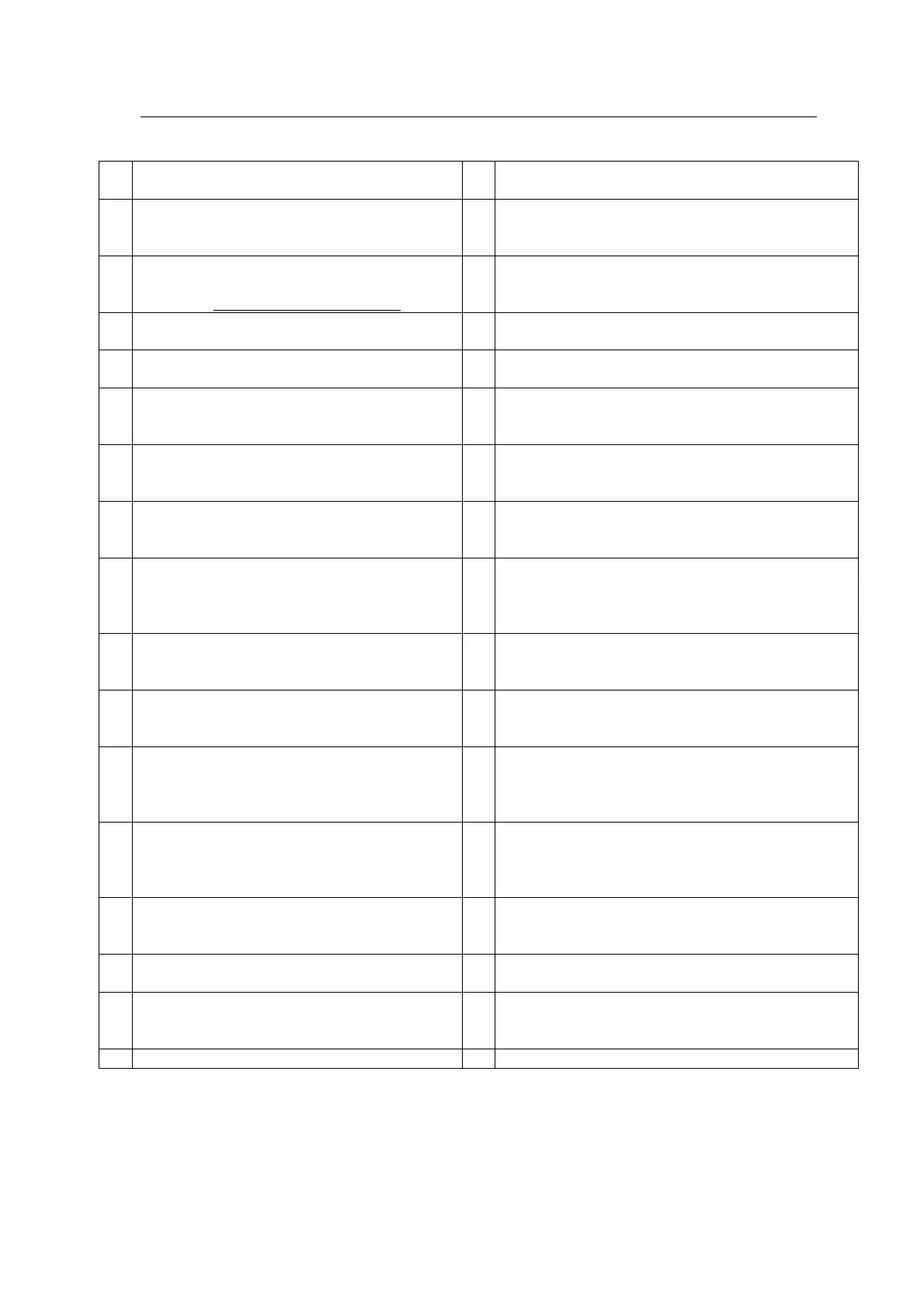

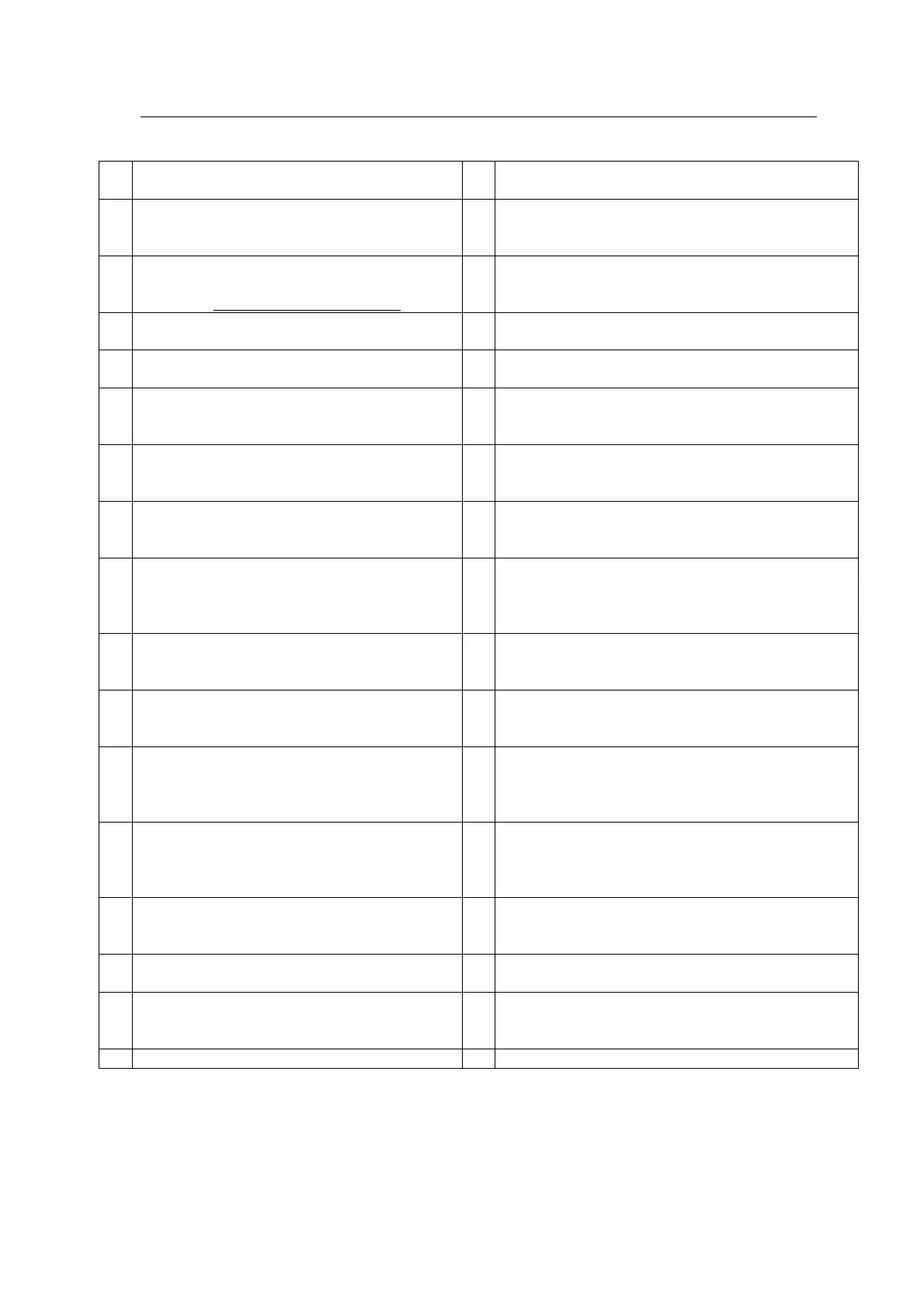

73

P12 /P15 /P18

10. Operating and Monitoring Systems 10.

1 Solvent filling valve:

For filling the machine with solvent.

17 Thermal sensor, distillation condenser:

Monitors the solvent temperature.

2 Sight-glass, still:

For observing the distillation process.

18 Thermal sensor, Slimsorba after carbon:

Monitors several temperatures during

maintenance.

3 Sight-glass, refrigeration unit:

For checking whether the cooling agent is free

of bubbles during the reduction phase.

19 Drying time controller:

Extends the drying time, depending on the type and

amount of garments

4 Sight-glasses, tank 3:

You can read off the liquid level on the scale.

20 Overfill sensor, safety separator: if overfilling,

diagnostic message appears.

5 Sight-glass, distillation:

Visual inspection of the condensate process

21 Sensor, low level: *

Regulates the detergent solution level.

6 Sight-glass, water separator:

Visual inspection of solvent-water-separate

layer.

22 Sensor, high level:

Regulates the detergent solution level.

7 Sight-glass, safety separator: *

For observing the process water and checking

the safety separator.

23 Overfill sensor, distillation: *

Stops the pumping process when the filling amount

has been reached.

8 Cooling water regulator, refrigeration unit:

You can set the condensation pressure in the

refrigeration unit here.

24 Low air pressure switch:

Monitors the compressed air supply. Set to 4 bar

(58 psi)

9 Cooling water regulator, distillation:

Regulates the cooling water flow (setting of

the cooling water temperature at drain

approximately +45 °C/113 °F)

25

26

Limit switches:

All maintenance openings are protected with limit

switches.

10 Low cooling water level switch

Monitors the cooling water supply.

Set to 1 bar (14.5 psi).

27 Pressure gauge, compressed air:

You can read off the required operating pressure (6

bar/87 psi) on the pressure gauge

11 High pressure control (refrigerating):

switches the system to the malfunction state if

there is overpressure

28 Manual valve, distillation steam:

For steam reduction.

12 Low pressure control (refrigerating):

switches the system to the malfunction state if

there is not enough cooling agent

29 Pressure relief valve, machine

(0.3 bar/4.4 psi):

Opens when the permissible operating pressure is

exceeded.

13 Thermal sensor, aftercooler:

Monitors the aftercooler temperature and

switches the machine off when the

temperature exceeds 40° C (104 ° F)

30 Pressure gauge steam generator Slimsorba (elec):

for visual inspection of the steam working pressure

and tightness (shows a negative value when cooled

off)

14 Thermal sensor, cage housing outlet:

Monitors the temperature at the air outlet.

31 Pressure control switch steam generator

Slimsorba (elec):

Controls the heater

15 Thermal sensor, solvent:

Monitors the solvent temperature.

32 Safety valve steam generator Slimsorba (elec):

Opens when the permissible pressure is exceeded

16 Thermal sensor, distillation:

Cuts off the distillation heater.

33 Aeration valve steam generator Slimsorba (elec):

Aeration when filling the heating chamber with

water

* Option

Loading...

Loading...