DIRECTIONS FOR THE INSTALLATION

− Automatic controls are safety devices and must not be

opened. The manufacturer’s responsibility and

guarantee are invalidated if the control is opened.

− For technical and safety reasons a regulation shutdown

must occur every 24 hours.

− The control can be mounted in any position.

− Live and neutral should be connected correctly; a

mistake could cause a dangerous situation.

− Make sure that the discharge of the ignition transformer

does not hit the detection probe.

− The earth terminal of the control, the metal frame of the

burner, the earth of the ignition transformer and the

earth of the main supply must be well connected.

− The connecting wire of the detection probe must not be

longer than 20 meters.

− Avoid putting the detection cable close to power or

ignition cables.

− Use a heat resistant cable and detection probe, well

insulated to the ground and protected from possible

moisture (or water in general).

− Always check the control before the first start and also

after any replacing or after a long period of non-

operation of the system.

− In particular make sure that:

− The connections are corresponding to the above

scheme.

− The intervention of limiters or dafety devices

causes a safety shutdown according to the

application.

− The level of the flame signal is sufficient.

− A short circuit between detection probe and burner

casing does not cause any flame simulation.

− In running state a detection probe leakage to earth

causes the lockout of the control.

TIMERS

The safety time is obtained by an electronic circuit which

makes the TS vary of not more than 4% with voltage (-15%

+10%) and temperature (-10 +60°C) variations.

The prepurge time is given by a compensated thermic

timer. This timer, combined with the corresponding

electronic circuit, allows a minimum prepurge time of 30

seconds, even in case of voltage variations (-15 +10%),

ambient temperature variations (-10 +60°C), interruption of

the current supply for any time, or frequent and repeated

starts of the unit. A further timer causes a lockout after a

postpurge time of about 5 seconds.

OPERATING CYCLE

When thermostats and gas pressure switch are closed, the

control box supplies the burner motor and the TP timer (in

series with BF and the BRA relay supply module). During

this first period (TP heating) the BF checks its own state

and its supply network; a flame simulation in this phase

causes the interruption of the TP heating and the lockout of

the device within 5 seconds. If it works properly, the TP

heating causes the switching of 2TP (after about 15

seconds) and 1TP (after about 30 seconds) in succession.

The commutation of 1TP stops the supply to TP, BF and

BRA, starting in this way the second stage (TP cooling):

The delay in the deenergization of BRA enables the BRB

relay to be supplied (through 1TP and 1A contacts) and to

restrain through 1B and PA.

If the PA contact is open (air flow failure), the

deenergization of the BRA relay is followed by the

deenergization of the BRB relay, therefore the device does

not continue its cycle, but remains in the prepurge stage. If

it works properly (PA closed), the energization of the BRB

relay is followed by the supply of the BRC relay: this stage,

with the cooling of TP, allows a minimum prepurge of 30

seconds.

The interruption of the electrical supply, or the temporary

opening of the air pressure switch, cause the repetition of

the whole starting cycle. In case of regular operation, the

TP cooling brings 1TP back to the starting position, and

with the BRB and BRC relay contacts in operating state,

the ignition stage begins, with the contemporary supply of

the BF thermal, of the ignition transformer and of the EV1

valve.

The ignition transformer and the EV1 valve are only

supplied during the safety time, which is determined by the

deenergization of BRC, taking place after 2 seconds; if the

burner starts operating within this delay, the BRF flame

relay contacts (1RF and 2RF) are switched, stopping the

supply to the BF lockout thermal and keeping the EV1

valve energized. The operating cycle is completed with the

EV2 valve control, provided after about 30 seconds by 2TP

going back to the starting position.

Flame failure prevents the commutation of 1RF and 2RF,

therefore at the end of the safety time only the BF lockout

thermal is still supplied, causing a lockout after 3 seconds.

If the flame extinguishes in normal running state, the

control closes both valves in less than 1 second and

performs a lockout after a postpurge time of about 5

seconds.

Abnormal operation:

− Air flow at start

The control performs a lockout within 5 seconds.

− Air flow failure at start

If the pressure switch is not commuted within 20

seconds, the prepurge stage continues.

− Air flow failure in running position

If the pressure switch contact opens, the device begins

the prepurge stage, which continues until the pressure

switch contact is open.

− Parasitic flame

The presence of a parasitic signal flame at start, or a

fault in the flame detection circuit leading to the same

condition, cause a lockout within 5 seconds.

CAUTION: If for any reason the burner system is not

equipped with air pressure switch, terminals n.4-6 must be

short-circuited instead of n.4-1. If terminals n.4-1 were

short-circuited, the control box would always perform a

lockout because of a stuck-contact simulation.

RESET OF THE CONTROL

To reset the control after a lockout, act on the button after

waiting for the restoration of the lockout thermal, which

normally takes about 20 seconds.

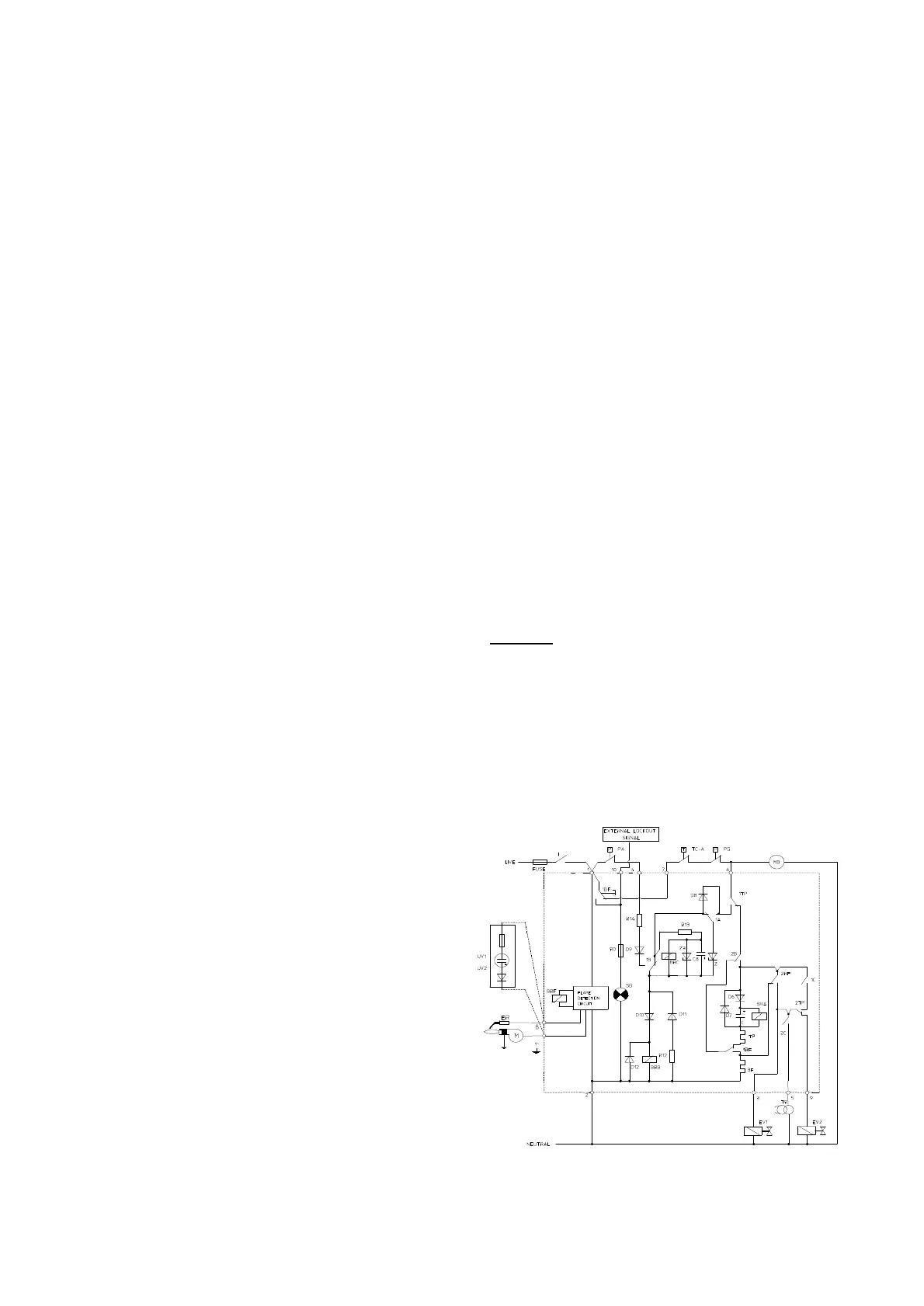

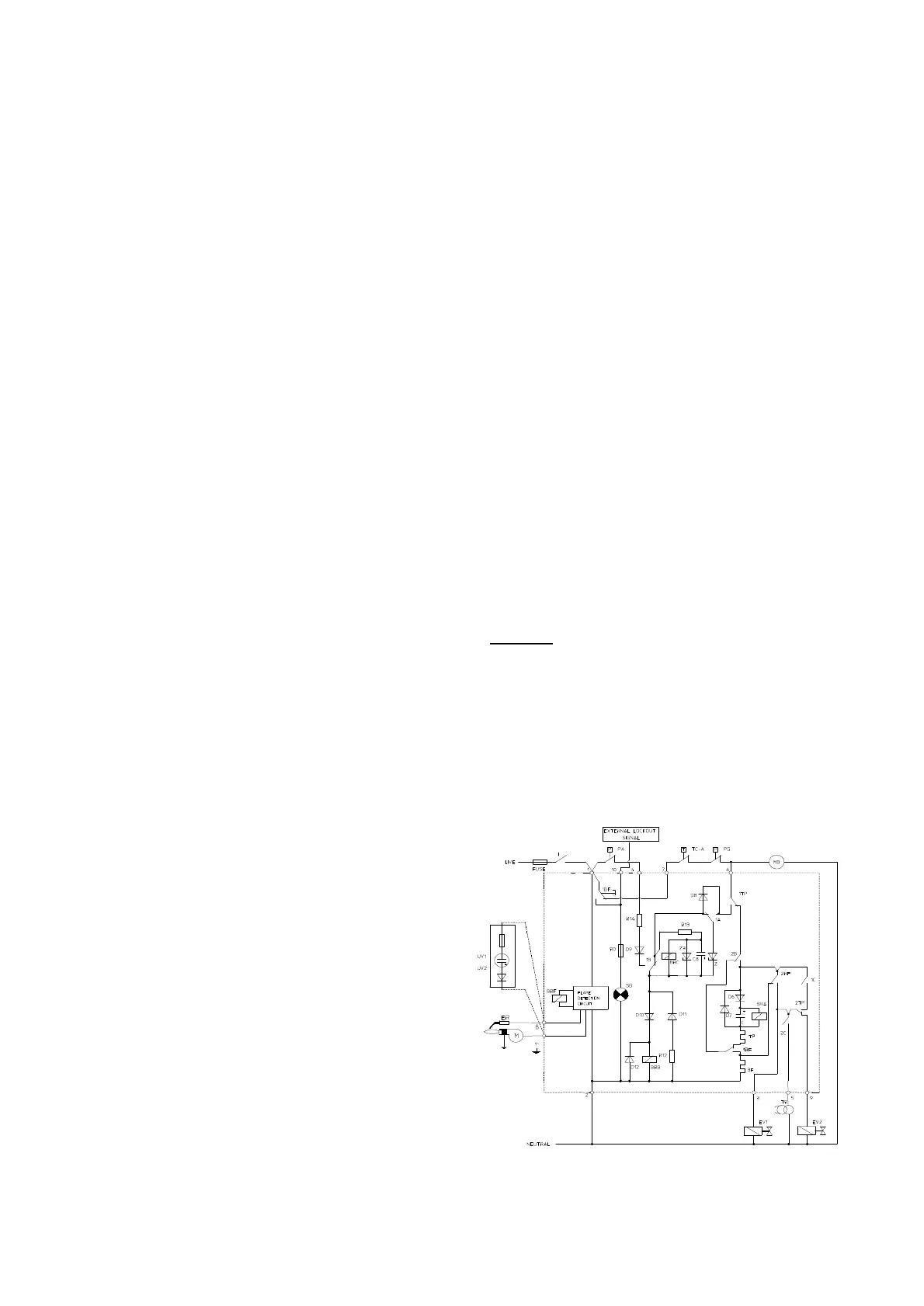

ELECTRICAL SCHEME

BF: Lockout and postpurge thermal M: Burner casing

BRA: Granted prepurge relay MB: Burner motor

BRB: Operation relay PA: Air pressure switch

BRC: Safety time relay PG: Gas pressure switch

BRF: Flame detection relay SB: Lockout signal

ER: Detection probe TP: Thermal programmer

EV1: First gas valve TC-A: Thermostats

EV2: Second gas valve UV1 UV2: Phototube

4015_r00 3/4

Loading...

Loading...