This machine has manual cable feed. The cable must be

fed by hand and does not automatically extend or retract

into the machine.

This machine should not be operated in reverse under

normal operating conditions. Reverse should be used only

for a few seconds at a time to free a stuck cutting tool.

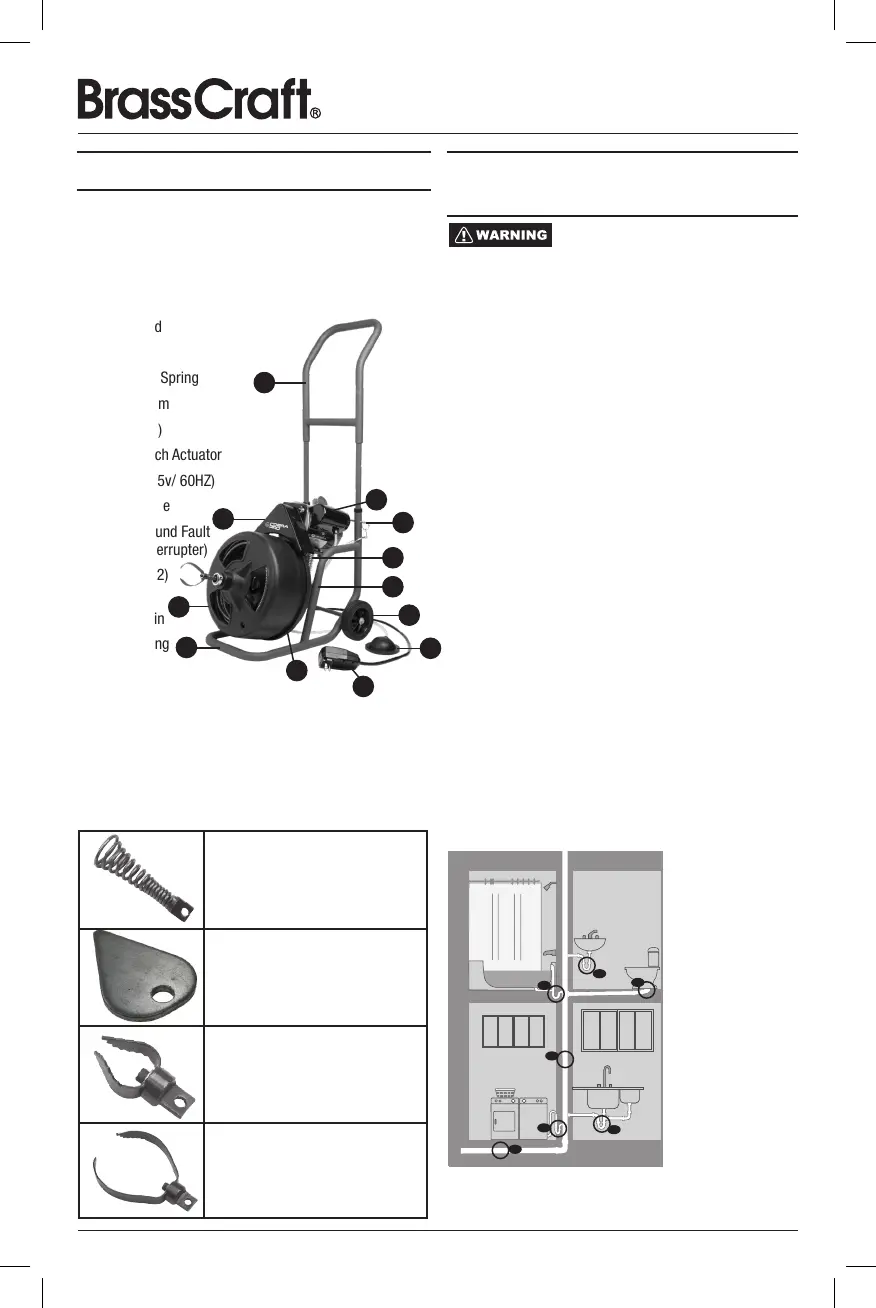

1. Belt Guard

2. Belt

3. Extension Spring

4. Cable Drum

5. Wheels (2)

6. Foot Switch Actuator

7. Motor (115v/ 60HZ)

8. Base Frame

9. GFCI (Ground Fault

Circuit Interrupter)

10. Uprights (2)

11. Frame

release pin

12. Telescoping

Handle

MACHINE DESCRIPTION

Tool Description

Your cable drum machine has four benecial tool

attachments to cope with a wide variety of obstructions.

As a general guideline, it is wise to use a tool that is at

least 1" smaller than the line to be cleared. The nature of

the job and the operator’s judgment should determine the

type of tool.

• ST-96205

• 3/4" x 5"

Straight Boring Head

for initial exploration of clog

• ST-96207

• 1-1/2" x 2"

Slotted Spear Head

for piercing clogs

• ST-96201

• 1-1/4" x 2"

Grease Cutter

for grease blockages

• ST-96208

• 2" x 4"

Side Cutter

for nishing pipe cleaning

PREPARATION

FOR OPERATION

Do not operate a machine that has the belt guard

removed, any absent or broken parts, or that is

incorrectly assembled. If your machine does not meet all

of the conditions in this section, do not operate until the

machine is properly repaired (See Repairing Your Drum

Machine). Failure to properly prepare for operation may

result in shock, re, and/or serious personal injury or death.

Check Your Personal Protective Equipment

Be sure your personal protective equipment (See

Personal Protection Equipment Section) is in good

condition. Before use, ensure gloves are not damaged.

Prepare the Work Area

• Make sure the work area has satisfactory lighting.

• Do not work in areas that have combustible liquids,

dust or vapors that may ignite. The drain machine is

not explosion resistant and can create sparks.

• Do not work in any area until all the amable

soruces have been identied and corrected.

• Never place the machine in water. If necessary

remove the water from the work area prior to use.

• Be sure the electrical outlet is properly grounded.

If unsure, have the outlet inspected by a licensed

electrician.

• Make sure the path for the power machine

transportation and power cord are clear of

obtsructions. Any potential sources of damage to the

power cord or machine should be relocated prior to use.

• Keep bystanders and childred away from the work area.

• Drain cleaning can be messy. If necessary, use

protective covers.

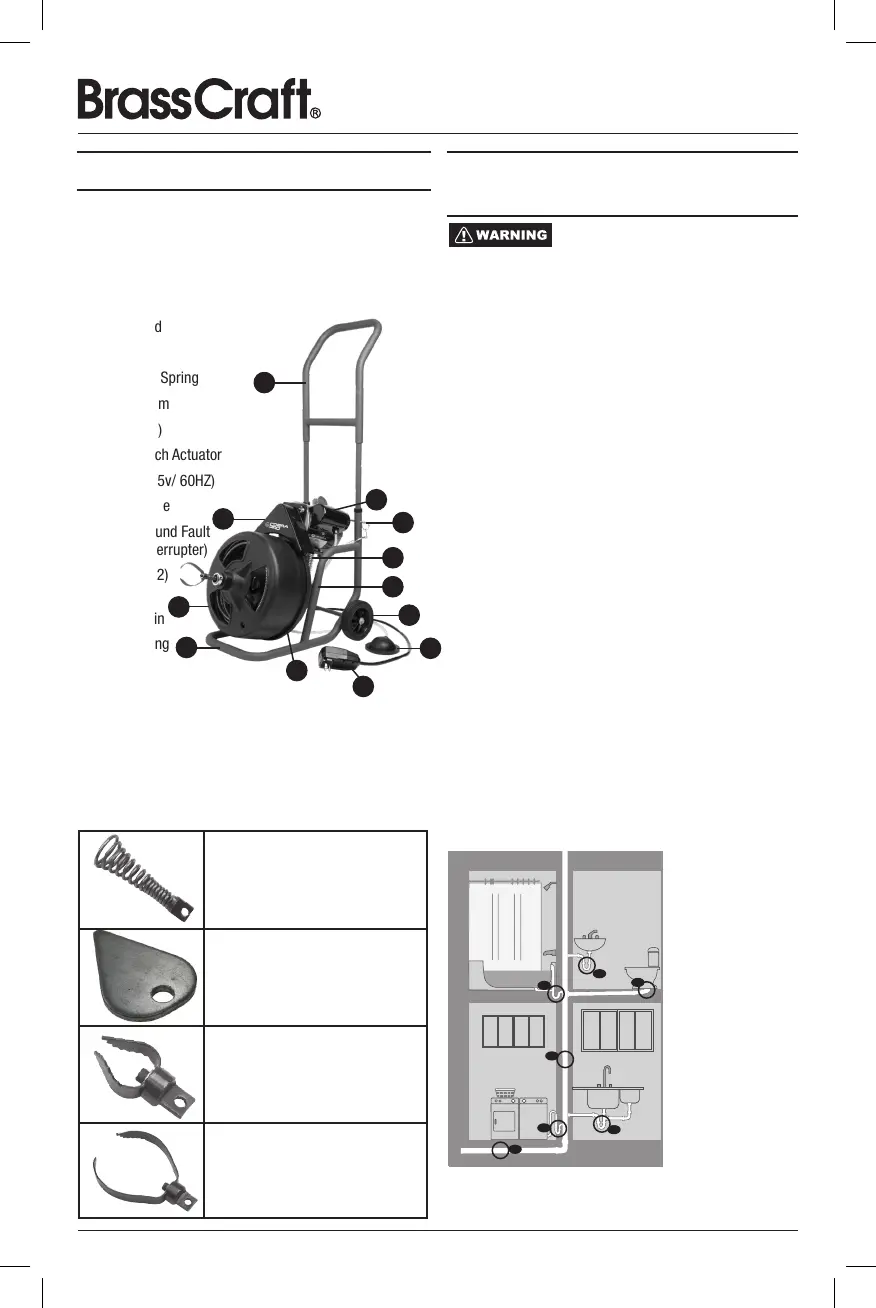

Inspect and Prepare the Drain

1

2

1

1

4

3

1

• Determine if

cleaning chemicals

have been used in

the drain. If

chemicals are

present, contact the

chemical

manufacture to

understand the

safety measures that

are necessary to

work around those

substances.

• Properly

inspect the drain.

Determine the best

access point to the

drain and the size of

the drain. If possible,

determine the distance to the blockage or the nature

of the clog. If necessary, remove the xture (toilet, sink,

etc.) to allow access to the drain.

4

7

5

3

1

6

8

2

10

12

11

9

Loading...

Loading...