BGM-SERIES OPERATION & MAINTENANCE MANUAL

3389 ~ 128

th

Avenue Holland, MI 49424 Phone: 616/399-5600 Fax 616/399-3084

Copyright 2015 BRAWN Mixer, Inc. www.BRAWNMIXER.com Page 3 of 9

8/6/2015

INSTALLATION, CONT.

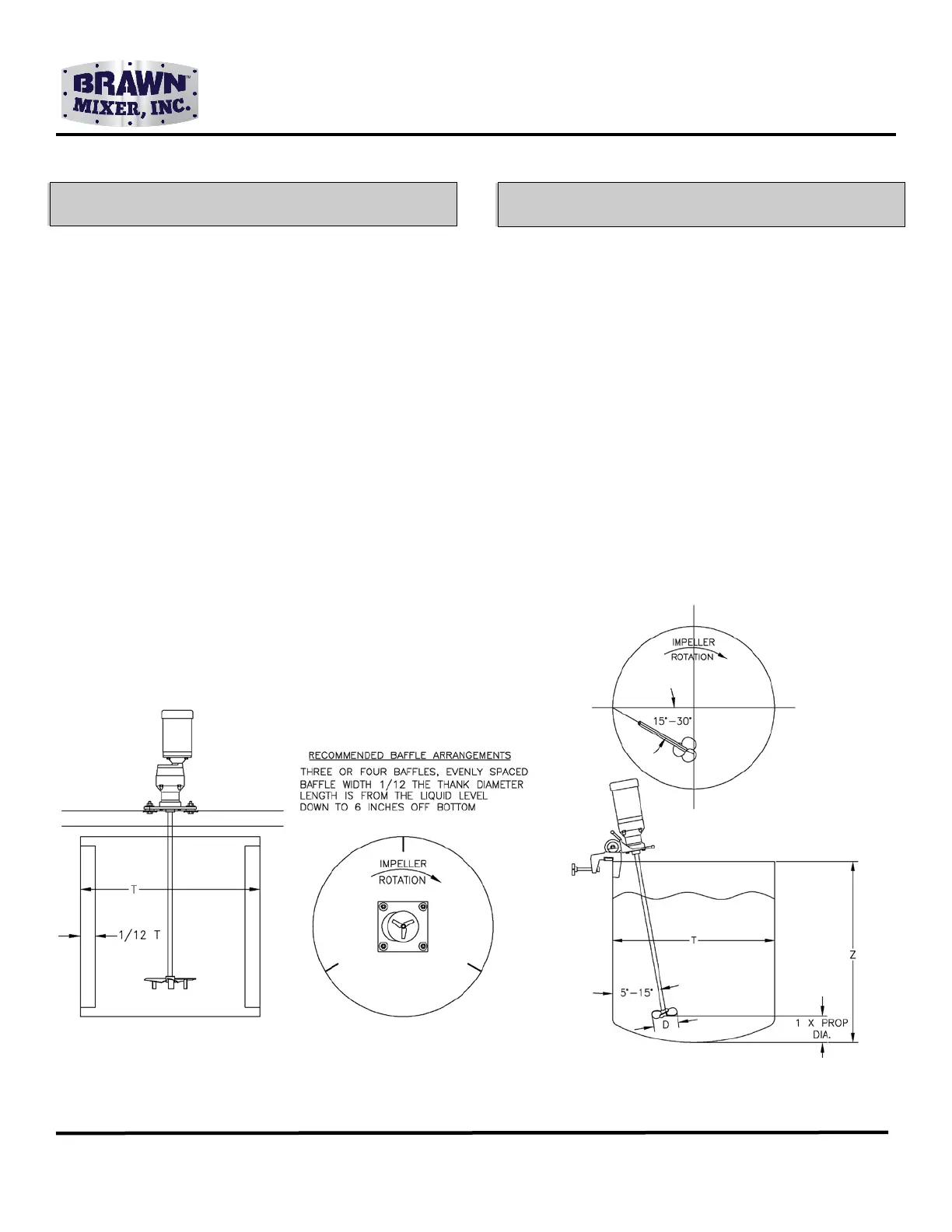

The following guidelines are based on mixing in vertical

cylindrical tanks with flat, dished, or shallow cone

bottoms. Mixer installations may vary with tank shape,

retention times, starting conditions and other

requirements.

1. For liquid levels 0.5 to 1.1 times the tank diameter, a

single impeller is suitable.

2. For liquid levels 1.1 to 1.6 times the tank diameter,

use dual impellers.

3. Impellers may be located from 0.5 to 2.0 impeller

diameters off the tank bottom, with one diameter off

bottom being optimum.

4. When dual impellers are necessary, spacing

between impellers should be approximately two

impeller diameters with gear drives, and four to five

impeller diameters with direct drive mixers.

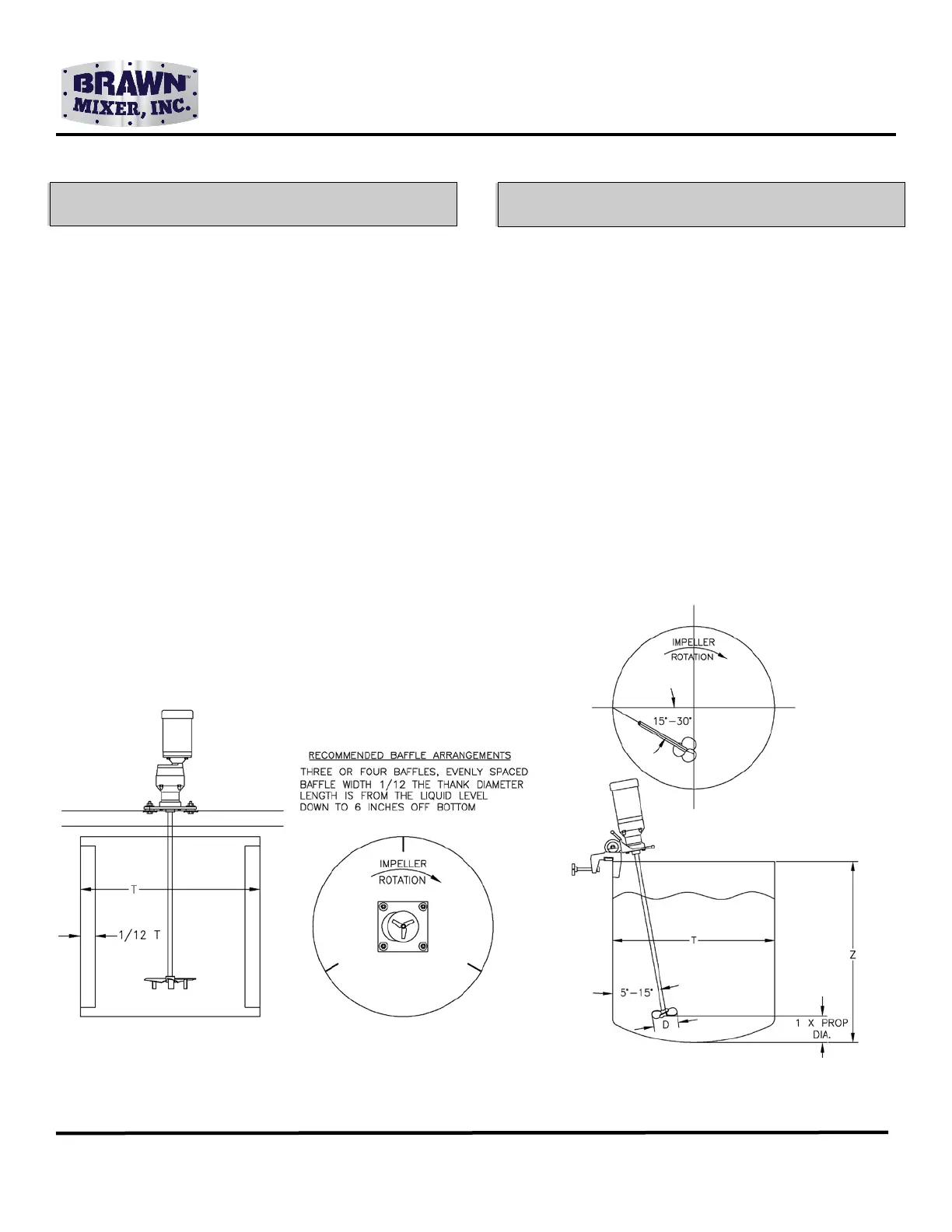

5. Mixer position in tank should be as shown in

FIGURE A or B [below] for maximum turnover of

liquid.

FIGURE A

START UP

1. All units are lubricated before shipment. The

lubricant level should be checked with the unit

positioned vertically. Lubricant should only be

added if the level is below the top of the gear. Do

not fill beyond the top of the gear.

2. Connect the motor in accordance with the motor

nameplate. The motor starter should incorporate

overload protection. Before operating the mixer, jog

the motor and observe mixer shaft rotation. Proper

rotation is clockwise, as viewed from the top, unless

otherwise noted.

3. Check all bolts and fasteners for tightness. It is

good maintenance practice to recheck all bolts after

two weeks of operation and periodically thereafter.

Refer to TABLE 1 for recommended torque values.

4. Do not attempt to start mixer with impellers buried

in solids or solidified liquids

FIGURE B

Loading...

Loading...