BGM-SERIES OPERATION & MAINTENANCE MANUAL

3389 ~ 128

th

Avenue Holland, MI 49424 Phone: 616/399-5600 Fax 616/399-3084

Copyright 2015 BRAWN Mixer, Inc. www.BRAWNMIXER.com Page 8 of 9

8/6/2015

LUBRICATION

Although the gear box is considered “lubricated for life”,

the oil level and condition should be checked periodically

for signs of degradation. It is factory filled with an AGMA

#7C gear lubricant, which is suitable for an ambient

temperature range from 30 to 100 degrees F. If the

application calls for outdoor installation in extremely cold

or extremely warm temperatures, or in corrosive

environments, consult the factory.

If it becomes necessary to change the gear lubricant, a

drain plug is conveniently provided on the bottom of the

gear housing under the motor pinion shaft. A fill plug is

located on the top of the housing, above the output gear.

Refill with 14 ounces of the recommended lubricant. With

the mixer positioned vertically, the fluid level should not

exceed the top of the gear. Over filling of the gear box

can cause premature seal failure due to thermal

expansion of the oil and overheating due to excessive

churning.

CAUTION

In the Food and Drug Industry (including animal food),

consult the lubrication supplier for recommendation of

lubricants which are acceptable to the Food and Drug

Administration and/or other authoritative bodies having

jurisdiction. Factory supplied oil is not suitable for these

applications or this industry.

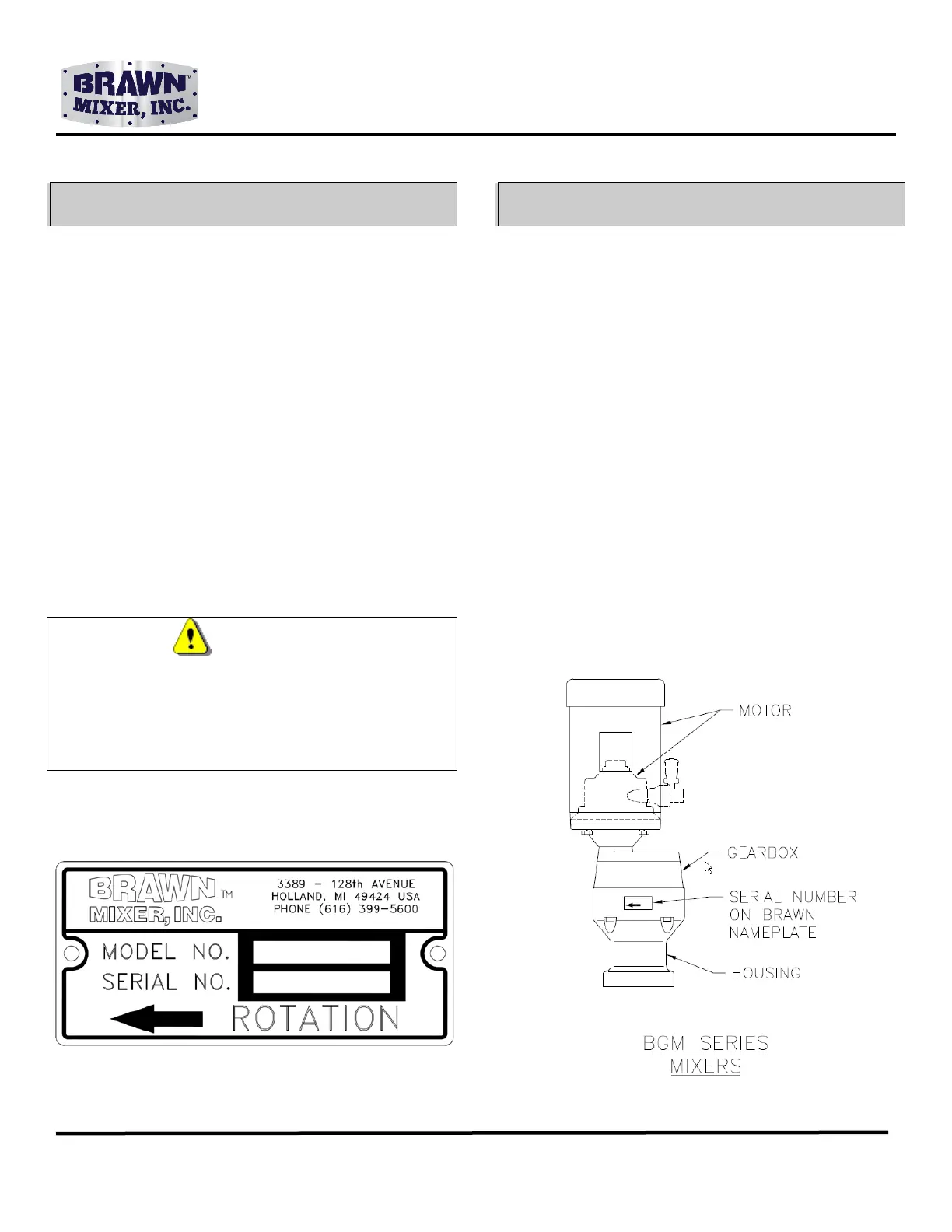

MIXER NAMEPLATE

STORAGE

Units shipped from Brawn Mixer, Inc. are intended to be

used within 30 days after receipt and presumed to be

stored indoors in a heated building. Store mixers as

packaged by the factory. If you intend storing units under

adverse conditions or for a long period of time, special

storage precautions will be necessary.

1. Store in a sheltered area away from chemical vapors or

steam.

2. Cover.

3. Do not store in sunlight or near high heat.

4. Spray light oil on exposed shafts and seals. Remove

oil on start-up.

5. Rotate output shaft 360º every 3-4 weeks.

6. Mixers should not be stored near vibrating machinery

to avoid damage to the bearings.

7. If electric motors have been subjected to humid

conditions, check the insulation resistance between

phase and mass and between the different phases.

The resistance should not be less than 100

megohms. If the resistance is less, please consult

the factory.

Loading...

Loading...