18

6. Cleaning and maintenance

6.1 Cleaning

Do not clean the device with compressed air!

Only clean from the outside using a lightly dampened cloth with the mains plug unplugged. Ensure that elec-

tronic parts do not come into contact with moisture. Do not use any cleaning products containing solvents!

6.2 Maintenance

Clean the holder for the mixing cup at the unit, the holder of the cup and the seal as well as the prefilter accor-

ding to the level of contamination. The prefilter is located in the mixing/suction connections (6). Switch the

device off and remove the mains plug before changing the prefilter. The prefilter is unfastened by turning it in

an anti-clockwise direction with the help of a size 15 fork wrench and is then cleaned in an ultrasonic bath.

It is then screwed tight again by turning it in a clockwise direction. We recommend changing the prefilter every

1 to 2 years. The prefilter should not just be cleaned once the vacuum takes longer to build up, but at regular

intervals, depending on how much the device is used.

CAUTION

Never operate the device without a prefilter.

The O-ring on the mixing/suction connections (6) and on the mixing spiral should be kept clean in order to

guarantee an optimum vacuum. The vacuum pump does not require maintenance.

7. Troubleshooting

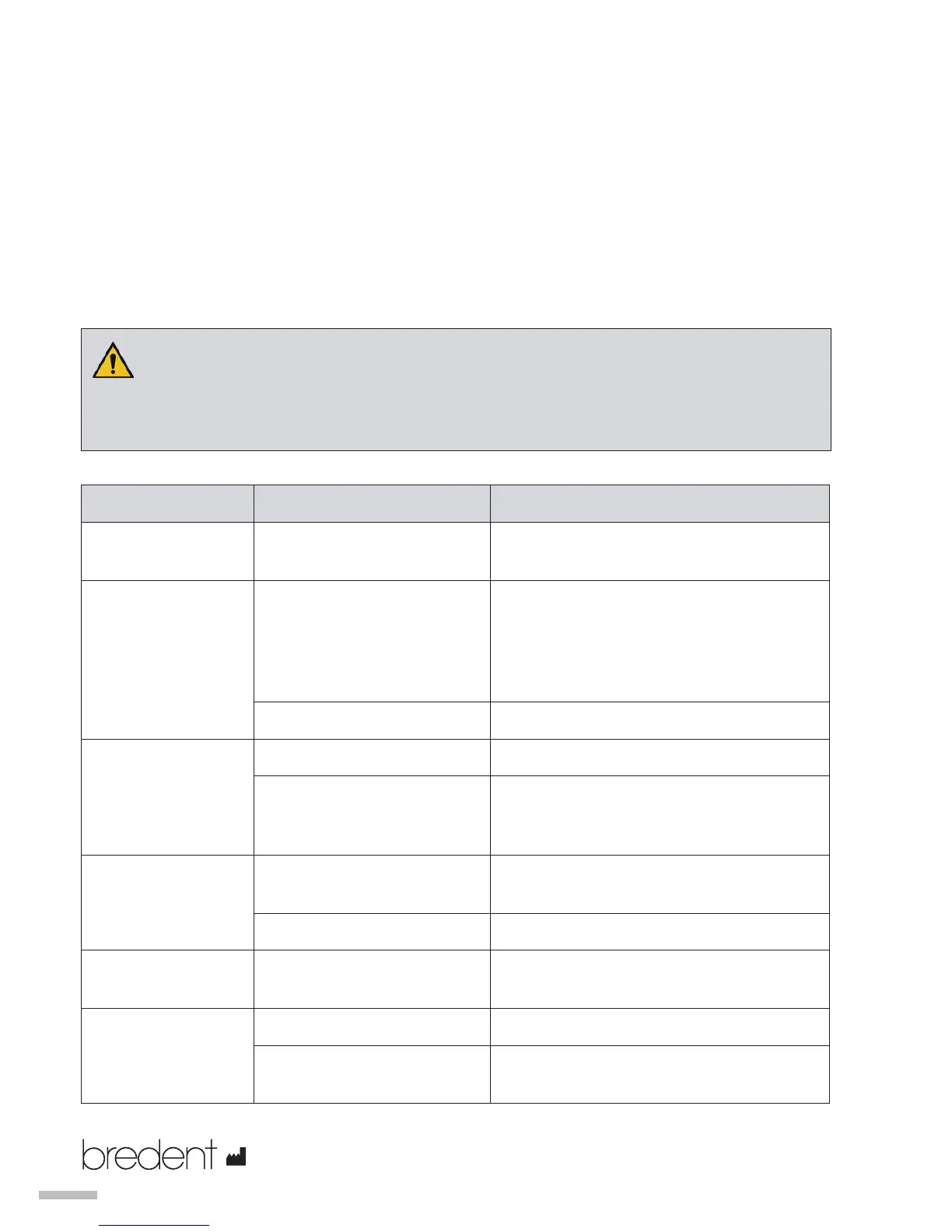

Fault Cause Troubleshooting

Device switches off! Motor is overloaded Restart!

Turn device „off“ and „on“ again.

Device does not start/

work!

LED display does not

illuminate!

Network data and/or

connections, parameters do

not match

- Compare data with type-plate

- Insert mains plug

- Switch mains switch (5) to „on“

- Set knob (3) to the recommended mixing

time (> 0 s)

Microfuse faulty Replace microfuse T 2.0 [A]

No vacuum build up

Vacuum pump defective Contact bredent and send device in if necessary

Seals are contaminated or

porous

- Keep seals on the mixing spiral and mixing/

suction connections clean

- Exchange porous seals

Vacuum builds up

but mixing cup does

not stay in place

Drilled hole in the lid of the

mixing spiral is blocked

Clean the plastic insert

Prefilter blocked Disassemble and clean prefilter

Device is too loud Sound absorber is broken or

missing entirely

Remove sound absorber residues/install

missing sound absorber

Mixing spiral is jerky

or mixing results are

not correct!

Electronic control Contact bredent and send device in if necessary

Mixing spiral is bent or

contaminated

Clean or replace!

bredent GmbH & Co.KG · Weissenhorner Str. 2 · 89250 Senden · Germany · Tel. +49 7309 872-22 · Fax +49 7309 872-24

www.bredent.com · e-mail info@bredent.com

Loading...

Loading...