NO.

IN

CHAPTER

8

FLOWCHART

AND

ERROR

STATUS

#16

The thread cannot

be

cut.

PROBABLE

CAUSES

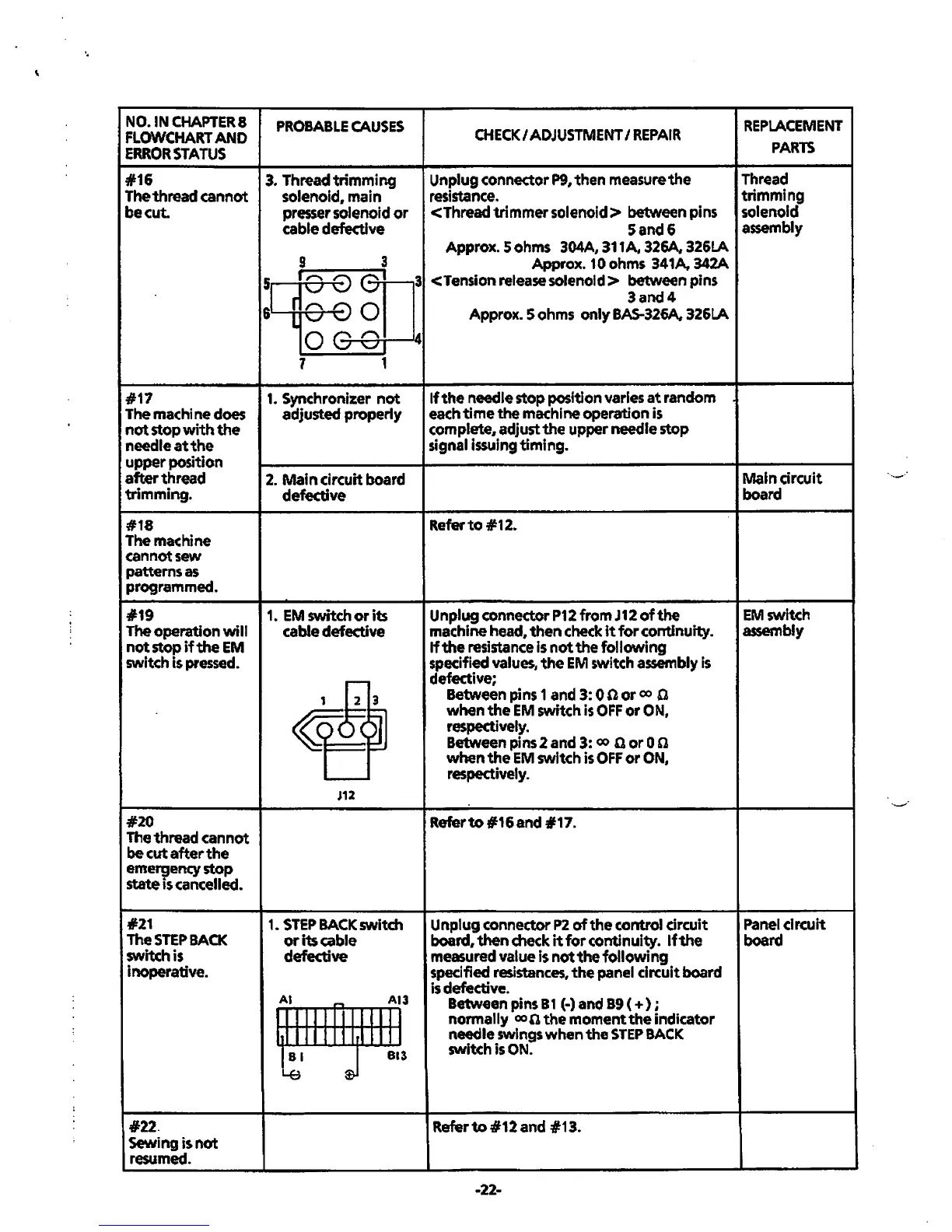

3.

Threadtrimming

solenoid, main

presser solenoid

or

cable defective

CHECK/

ADJUSTMENT

I

REPAIR

Unplug connector

P9,

then

measure

the

resistance.

<Thread trimmer

solenoid>

between pins

Sand&

Approx. Sohms 304A, 311A, 326A. 326LA

9

3 Approx. 10 ohms 341A, 342A

5]

I 0 B

e....;...r.-

1

-----.3

<Tension release

solenoid>

between pins

r

3and4

6 l C 0 Approx. 5 ohms

only

BAS-326A. 326LA

OGC

1 1

#17

1.

Synchronizer

not

The

machine does adjusted properly

not

stop

with

the

needle

at

the

upper position

after

thread

2.

Mal n circuit board

trimming. defective

#18

The machine

cannot sew

patterns as

programmed.

4

If

the

needle stop position varies

at

random

each

time

the ma<hine operation is

complete, adjust

the

upper needle stop

signal issuing timing.

Refer

to

#12.

REPLACEMENT

PARTS

Thread

trimming

solenoid

assembly

Main

circuit

board

Unplug connector

P12

from

J12

of

the

EM

switch

machine head, then

check

it

for

continuity. assembly

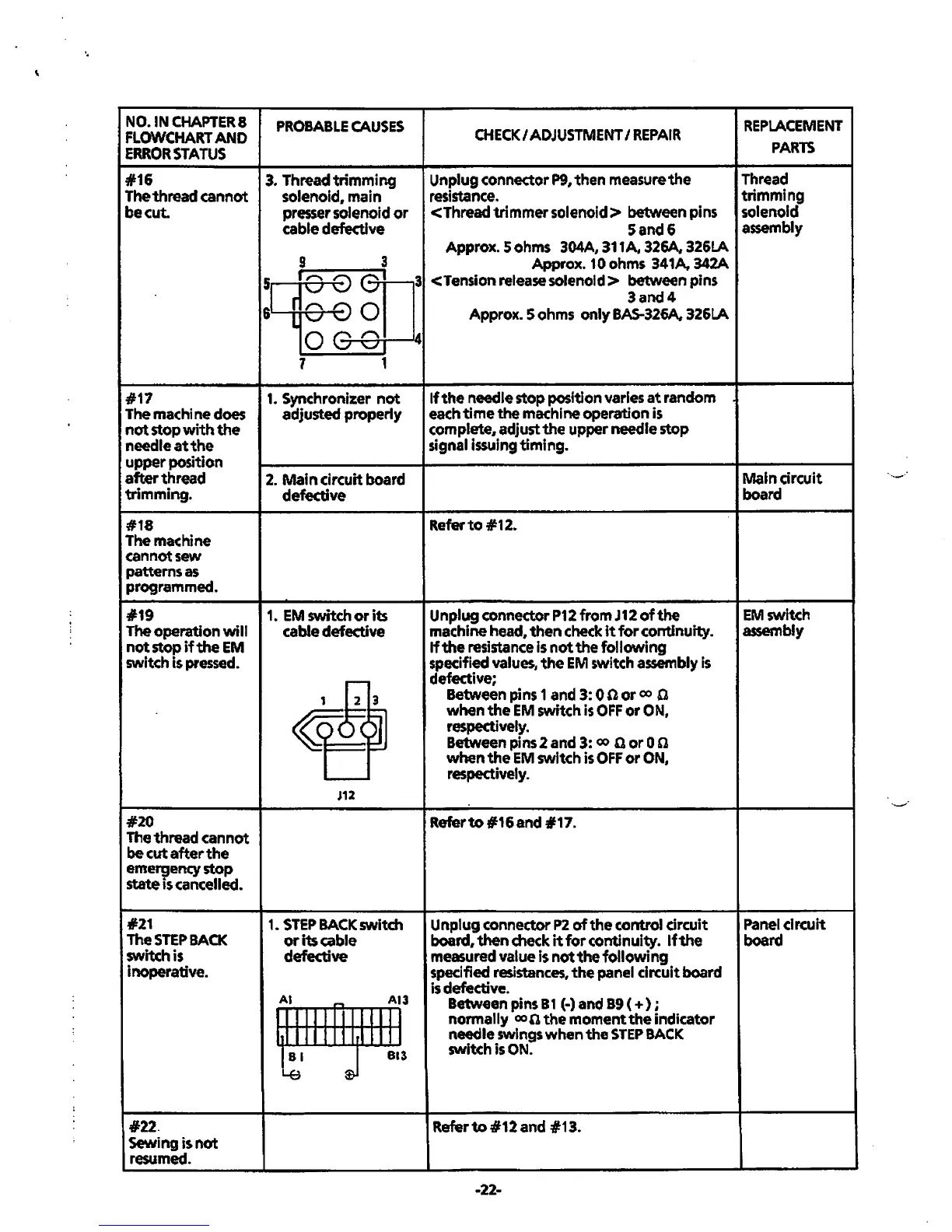

#19

1.

EM

switch

or

its

The operation

will

cable defective

not

stop if

the

EM

switch is pressed.

#20

The thread cannot

be

cut

after

the

emergency stop

state

is

cancelled.

#21

The

STEP

BACK

switch is

inoperative.

#22.

Sewing is

not

resumed.

J12

1.

STEP

BACK

switch

or

its cable

defective

Al

r-.

Al3

II

IIIIIIIIIJJ

I

hllllllllrlllll

~I

J Bl3

If

the

resistance is

not

the

following

specified values,

the

EM

switch assembly

is

defective;

Between pins 1 and 3:

0

nor

co 0

when

the

EM

switch

is

OFF

or

ON,

respectively.

Between pins 2 and 3: co Q

oro

n

when

the

EM

switch

is

OFF

or

ON,

respectively.

Referto#16and

#17.

Unplug connector

P2

of

the

control

drcuit

board,

then

check

it

for

continuity.

If

the

measured value is

not

the

following

specified resistances,

the

panel circuit board

is

defective.

Between pins B 1

(·) and

B9

(

+)

;

normally co 0

the

moment

the

indicator

needle

swings

when

the

STEP

BACK

switch is

ON.

Referto#12and

#13.

-22-

Panel circuit

board

..._·

Loading...

Loading...