5 - 3

SERVICE section 5

Drawing 7

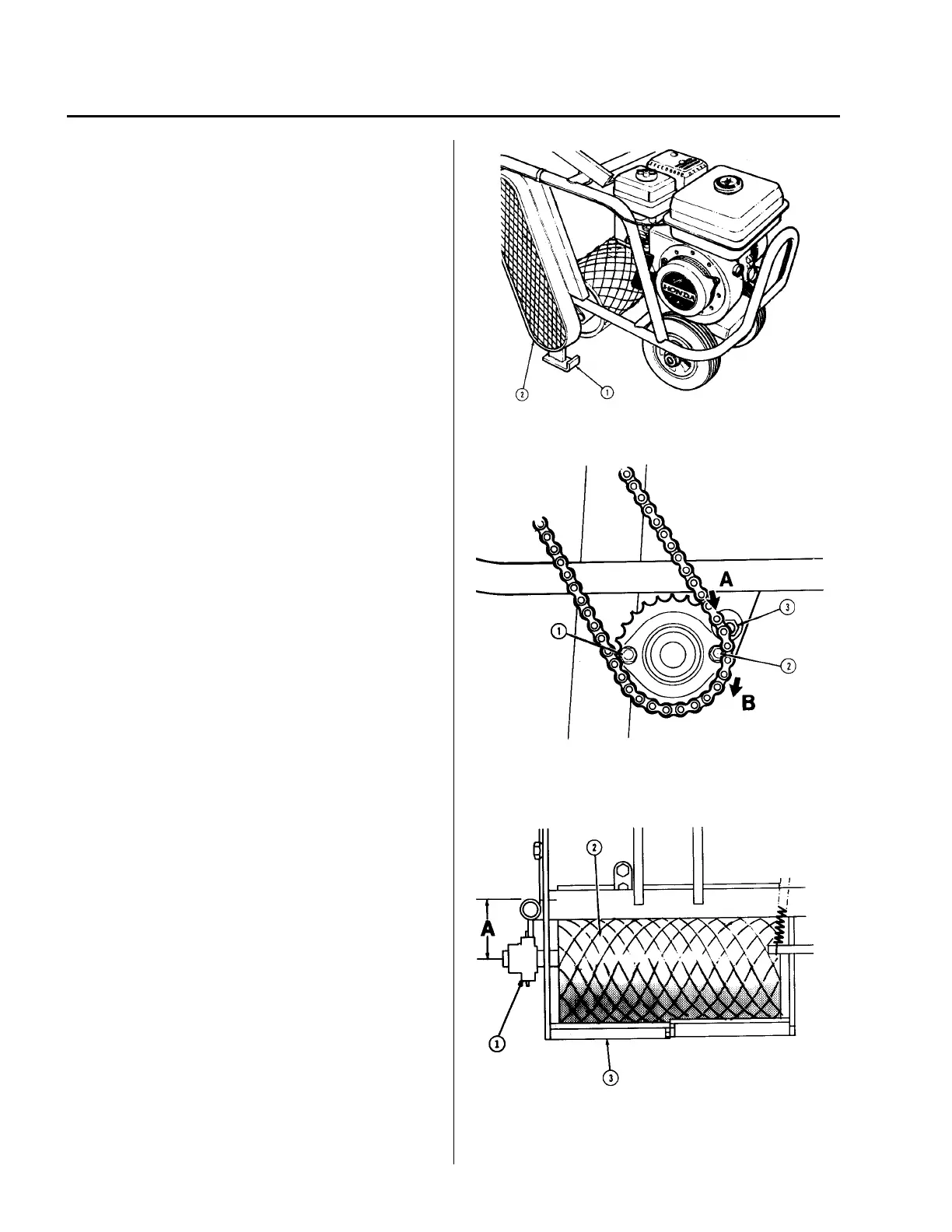

Drive Chain Adjustment/Replacement

See Drawing 7. Place machine on it's kickstand (1).

Remove the chain guard (2).

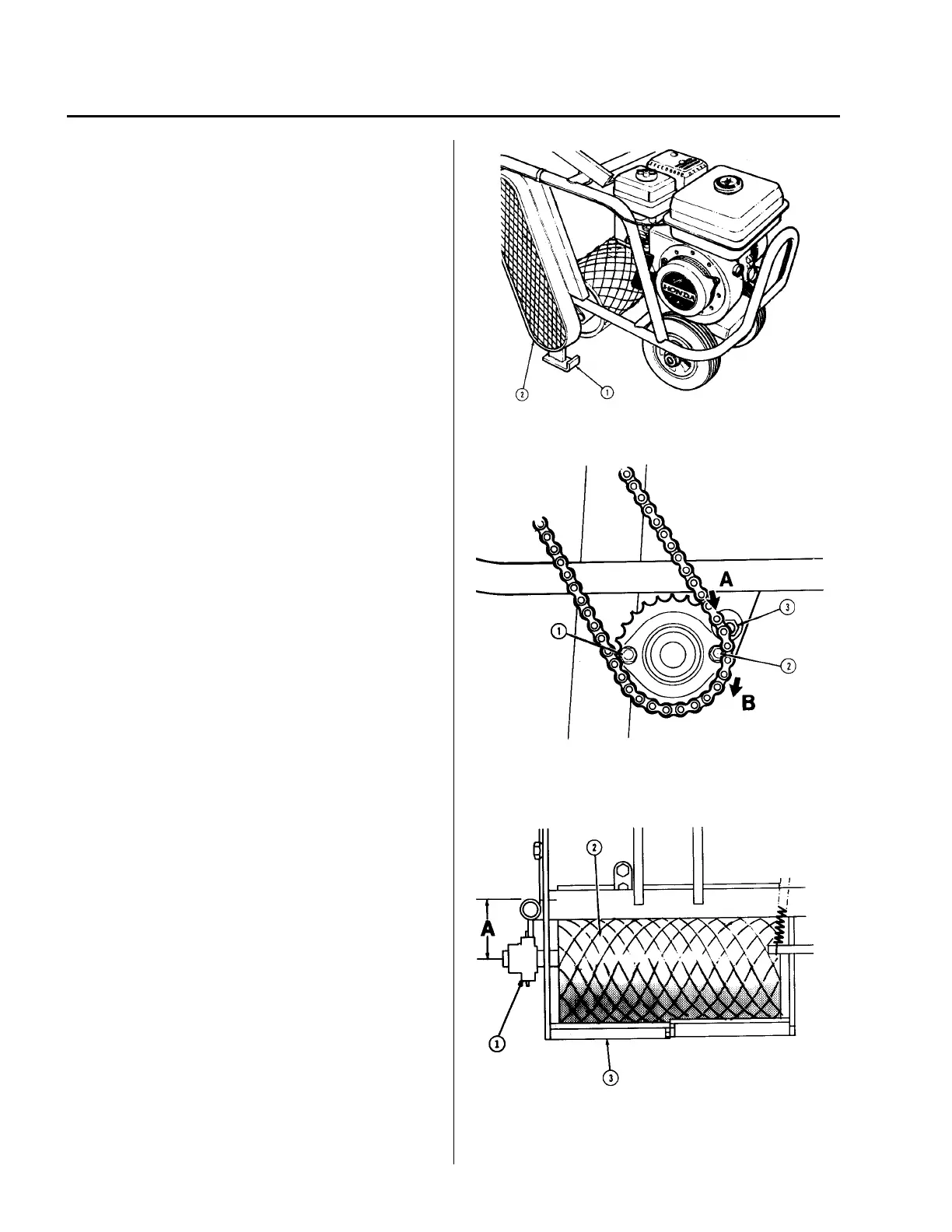

See Drawing 8. Slacken off the roller support

bearing housing bolts (1) & (2) and the eccentric

washer retaining bolts (3), on both sides of the

machine. Tap the bearing flange at point “A” to pivot

the bearing in the direction of arrow “B” and so

tightening the chain. Adjust the chain until there is

1/4 inch deflection between sprocket centers.

Re-tighten the bolts (1) & (2). Turn the eccentric

washers until they are hard against the bearing

flange and tighten the bolt (3).

See Drawing 9. NOTE: When adjusting the roller

bearings (1), it is important that the roller (2) remains

parallel to the cutting blades (3). check that

dimension “A” is equal on both sides of the machine.

Failure to do so may result in uneven thickness of

cut and premature chain wear or breakage.

Drawing 8

Drawing 9

Loading...

Loading...