BRP-Rotax

MAINTENANCE MANUAL LINE

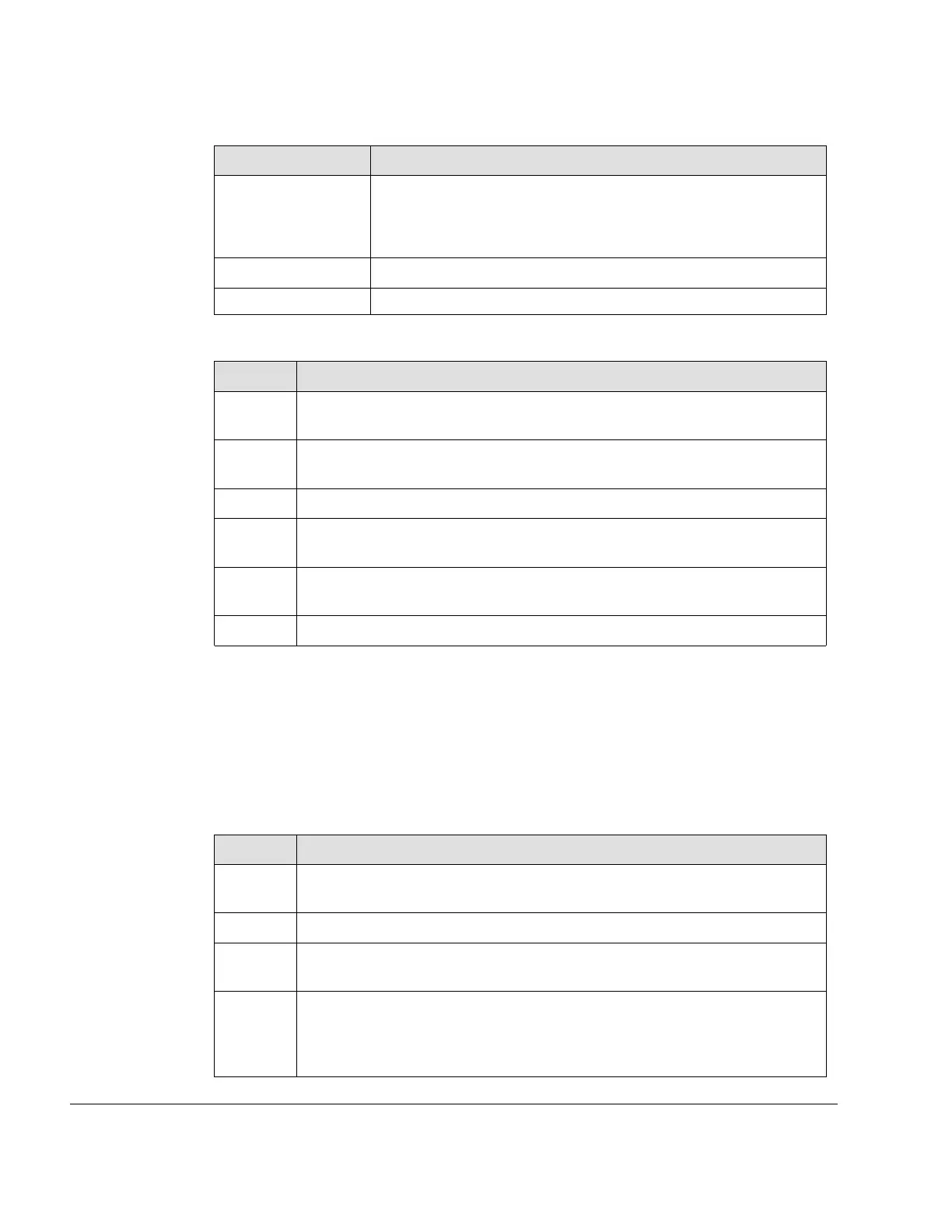

Part number Description

n.a

Orifice jet*, of 1 mm (0.04 in) inner diameter and 3 mm (0.12 in)

length. * or equivalent e.g. orifice diameter 0.040 in., long 0.0250

in., 60° degree approach angle according to AC43.13, latest

issue.

n.a

Adapter to spark plug thread.

n.a

Connect line.

Instruction Testing is carried out using the differential pressure test procedure.

Step

Procedure

1

Operate the engine until the temperatures have stabilized for a period of 5

min. (engine oil temperature between 50 to 70 °C (122 - 160 °F).

2

Remove the upper and lower spark plugs. Prevent dirt or other foreigner

particles from penetrating the engine (A).

3 Starting with cylinder head 1 move piston to TDC position.

4

Screw adaptor (1) into the spark plug thread and connect up the two pres-

sure gauges (2) with the orifice jet (3) between them (B).

5

Now secure the propeller and put constant pressure, between 5.5-6 bar

(80-87 psi) on the line and take readings at pressure gauge (C).

6 Repeat this proceeding at all 4 cylinder heads.

Value The maximum permissible pressure drop is 25 %.

Procedure if maximum permissible pressure drop is out of range:

Recheck the readings after operating the engine in a test run for at least 3 minutes. This

will allow the piston rings to be wetted with oil. Measure the pressure drop again as de-

scribed in the differential pressure test procedure. If the pressure loss is still out of range,

valve seat debris removal procedure must be carried out.

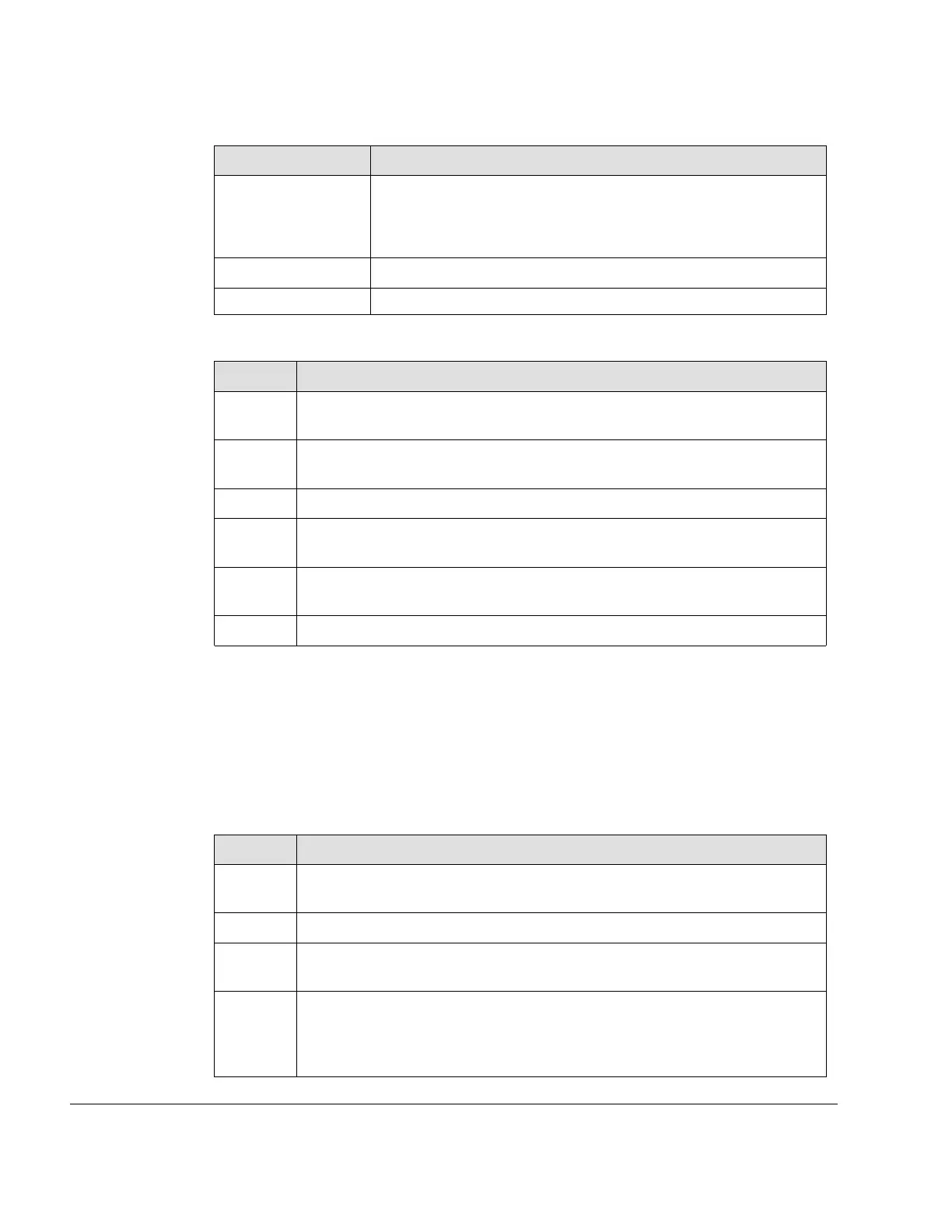

Valve seat debris removal procedure

Step

Procedure

1 Remove the valve cover according to the latest Maintenance Manual Heavy

(MMH).

2

Turn the crankshaft into the position, so that the intake valve is closed.

3

Place a plastic drift (2) on the rocker arm (1) (directly over the inlet valve

stem). See following figure.

4 During this step the cylinder must be pressurized by using the setup used

for the differential pressure check to allow carrying away debris from the

valve seat. Use a hammer to give a slight blow onto the fibre drift to dis-

lodge any foreign material between the intake valve face and seat.

12–20–00

Page 10

December 01 2023

Effectivity: 916 i A / C24

Edition 0/Rev. 1

Loading...

Loading...