BRP-Rotax

MAINTENANCE MANUAL LINE

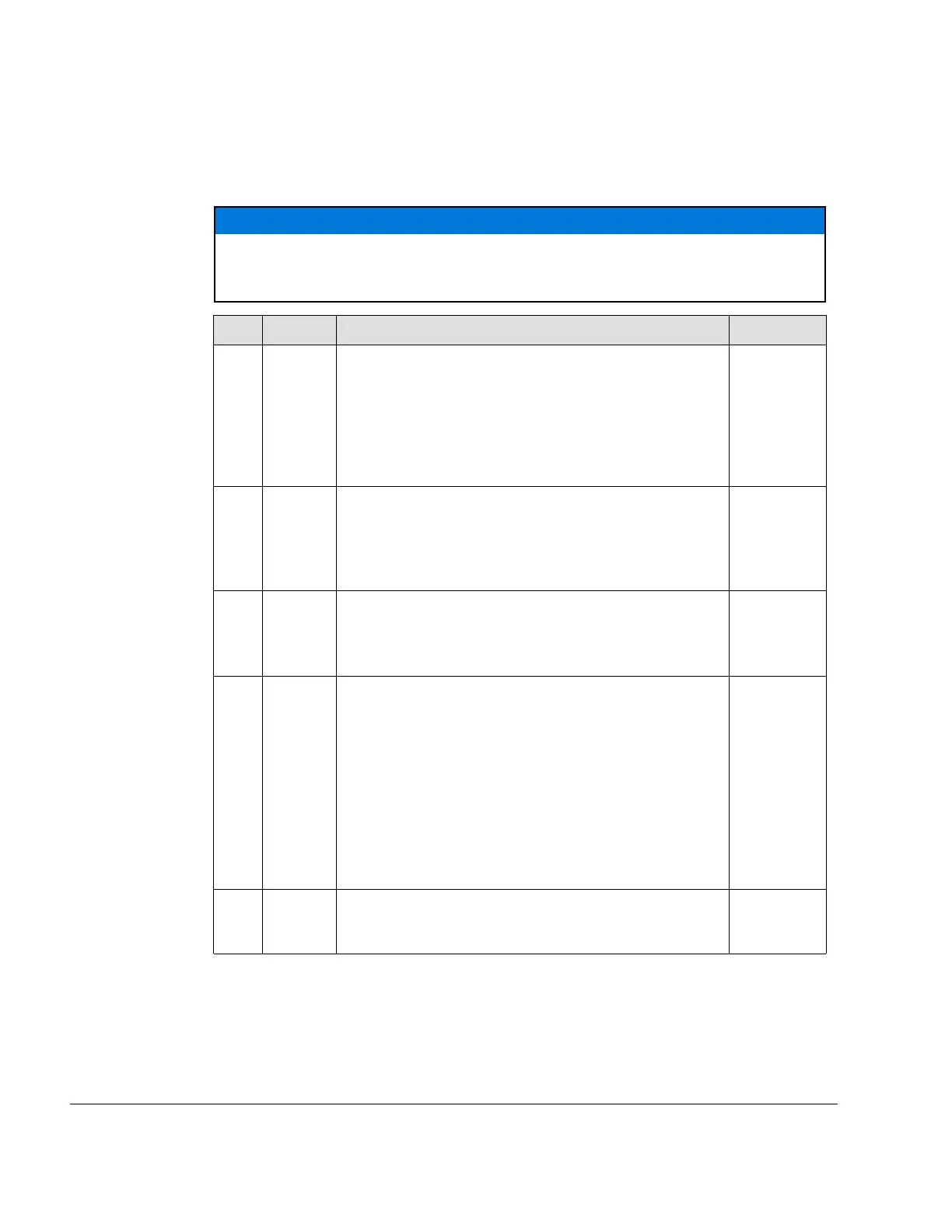

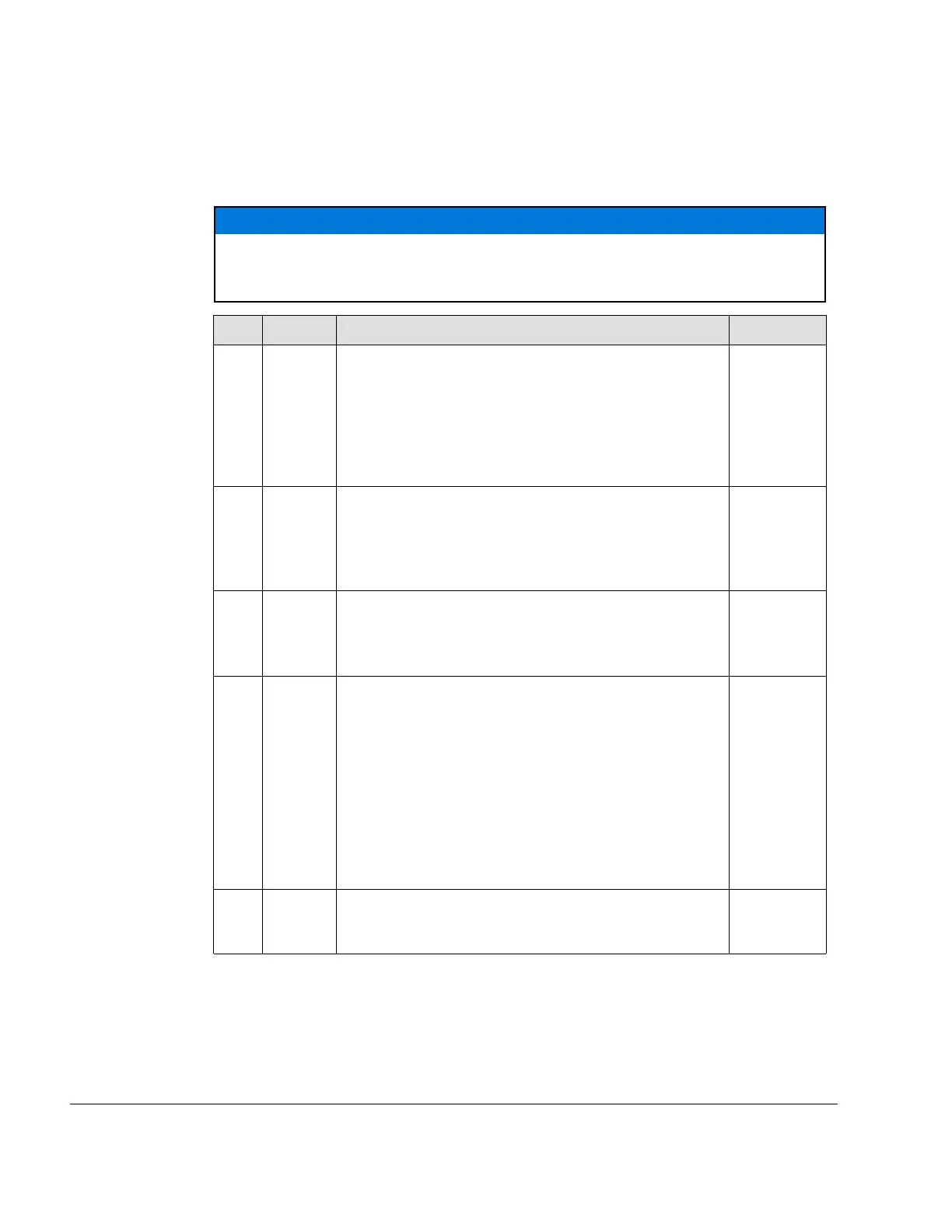

Additional

materials

NOTICE

All metal and synthetic parts should be cleaned with suitable cleaning agents.

Before using new and unknown cleaning agents, check their compatibility with

the materials they are being used on.

No. Part no. Description, application

Qty.

1

n.a.

Cleaning agent/solvent/parts cleaner

Soak combustion chamber, piston and cylinder head

with cleaning agent and remove combustion residues

with a bronze brush. Cleaning agents that are solvent -

cold cleaner, free of halogen, on the basis of selected

fuel fractions and biodegradable are recommended.

Never use caustic or corrosive cleaning agents.

AR

2

n.a.

Multipurpose grease

Generally usable, neutrally colored multipurpose

grease, water resistant and highly adherent. Usable for

temperatures from -35 °C to +120 °C (-31 °F to 248 °F)

and can be subjected to high mechanical loads.

AR

3

n.a.

Preservation oil

This special oil has excellent penetrating capabilities

and reaches even tiny gaps, its highly effective addi-

tives protect against corrosion of metal surfaces.

AR

4

n.a.

Flexible web for surface finishing 3M Scotch-Brite

Multi Flex - very fine or ultra fine (or equivalent)

Is sold by the meter and used for manual removal of

smaller rust spots or oxidation, especially for optimum

ground connections. It is particularly suitable for remov-

ing LOCTITE from surfaces or threads to make them

metallic clean. Before re-applying LOCTITE, clean sur-

faces with nitrothinner or degreasing agent (CASTROL

ZA 30 or OMV - SOFT SOL). When using solvents, ob-

serve the safety regulations for persons and the

environment.

AR

5

n.a.

MS4 / DC4 corning #4 (or equivalent)

Electrical insulation compound for protection of electri-

cal connections.

AR

05–00–00

Page 10

December 01 2023

Effectivity: 916 i A / C24

Edition 0/Rev. 1

Loading...

Loading...