1.9 BURNERS AND GAS TRAINS - ATMOSPHERIC BOILERS

1.9.1 GAS BURNER ASSEMBLY

The gas burner in theses boilers is an assembly

of burner tubes, along with the necessary fittings,

valves, and safety devices. The gas orifices in the

burners are sized to deliver the proper amount of

gas flow to achieve maximum boiler ratings at the

rated manifold pressure listed on the boiler

nameplate. Table 1.9A has average manifold

readings for the atmospheric boilers. A tapping is

supplied on the manifold for this purpose. A U-

tube manometer is recommended for accurate

setting of the manifold gas pressure. See "Start-

up and Operation", Section 2 of this manual.

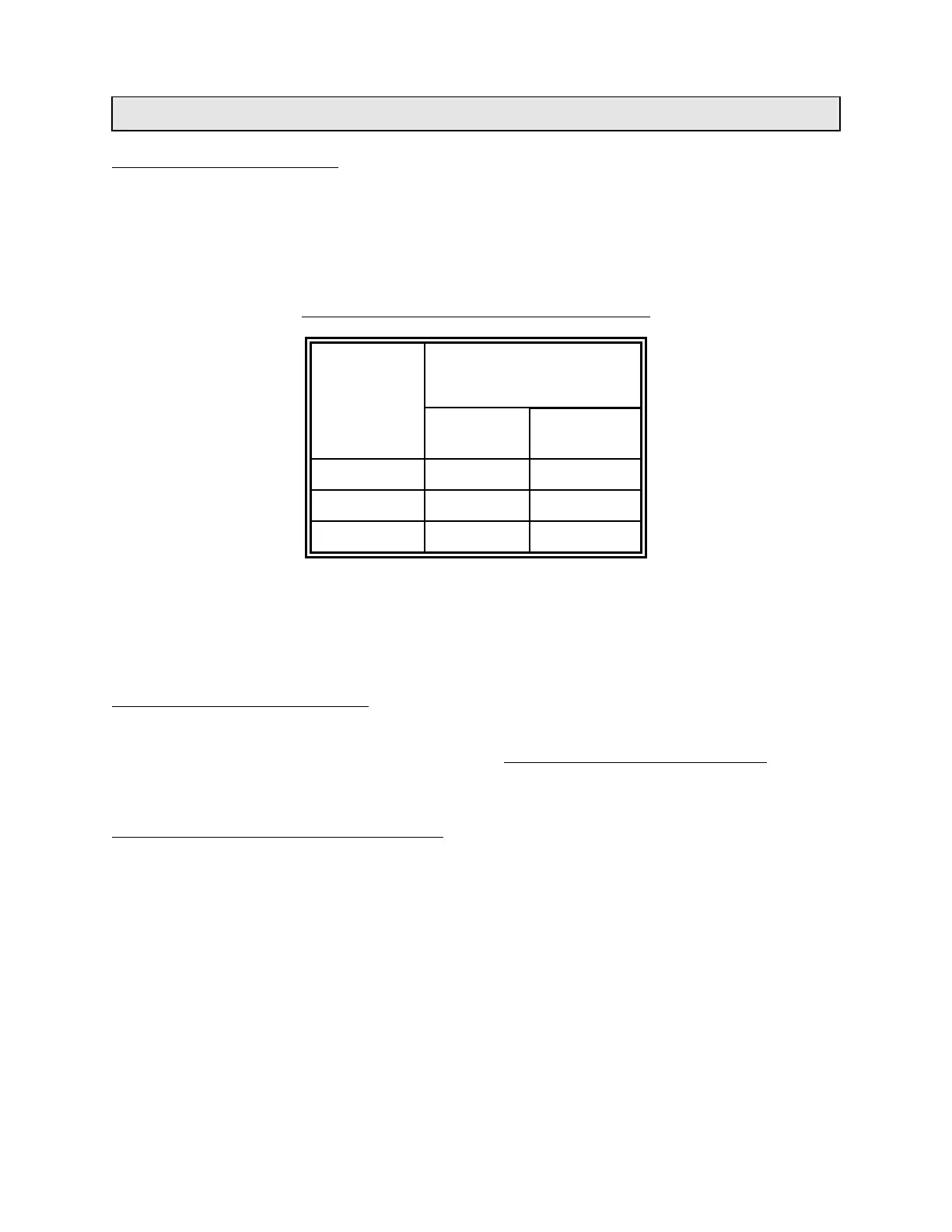

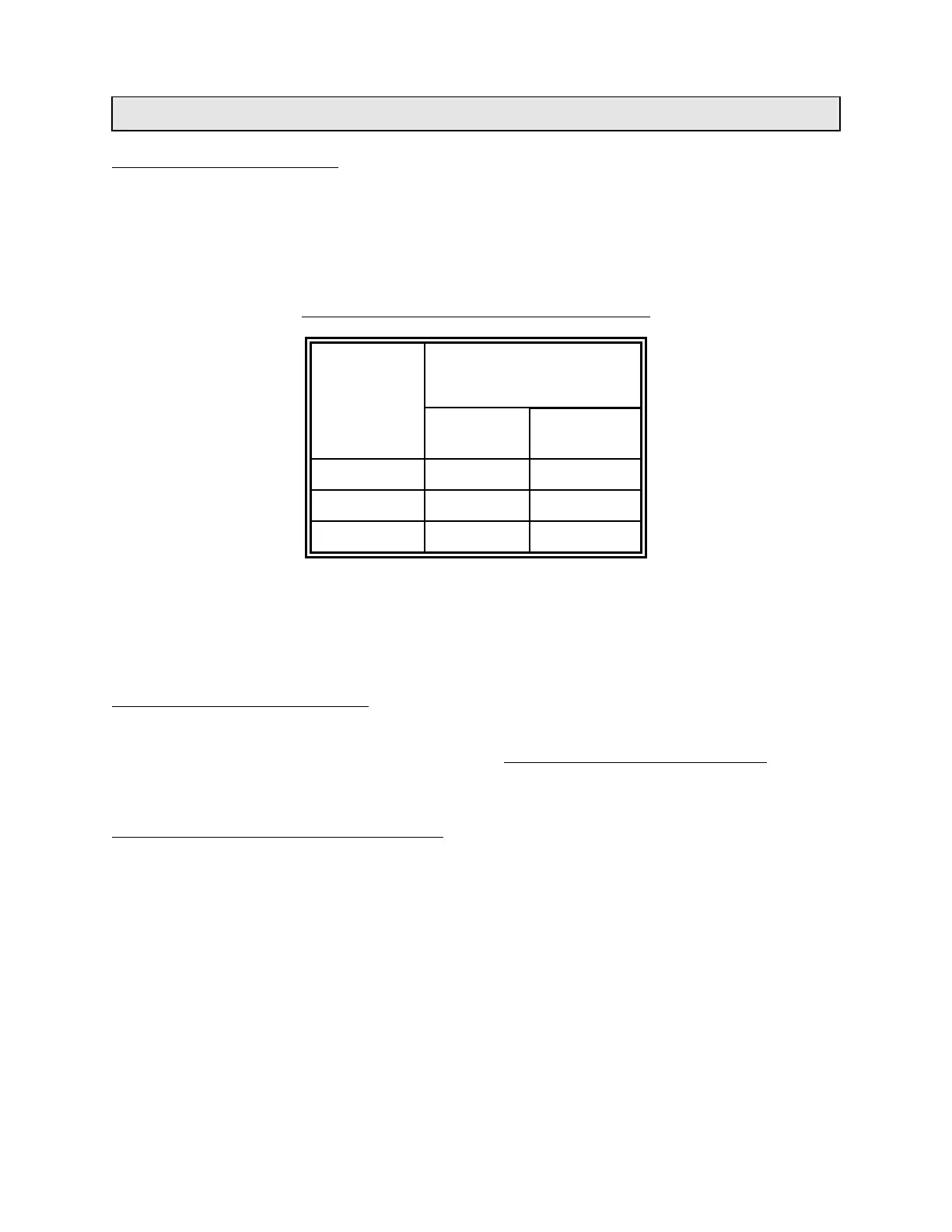

TABLE 1.9A: Approximate Boiler Manifold Pressure

BOILER

MODEL

MANIFOLD PRESSURE

LOW FIRE

(i.w.c.)

HIGH FIRE

(i.w.c)

F 1" 4"

CL 1" 3.5"

K 1" 4"

NOTE 1: Above gas pressures are for natural gas fuel only. For propane, high fire pressure is 11" w.c. and

2.5" w.c. at low fire.

NOTE 2: Reference manifold pressure on boiler nameplate.

NOTE 3: Above gas manifold pressures are approximate values only. Using a gas meter is the best way to

ensure correct input.

BOILER COMPONENTS - GENERAL

The boiler Equipment List in this manual lists the

gas train components. A description of the major

components follows. Refer to Lighting Instructions

and the manufacturer's literature on the

components included in the manual.

MAIN GAS COCK (MANUAL SHUTOFF VALVE)

The main shutoff cock is located in the gas line

ahead of the main gas pressure regulator. This

manual valve must be CLOSED during servicing

of the burners. DO NOT OPEN THIS VALVE IF

THE AUTOMATIC GAS VALVES ARE OPEN.

Refer to Section 2 of this manual and to Lighting

Instructions for proper use of this valve. A second

shutoff cock is sometimes supplied between the

burners and the automatic gas valves.

On some boilers utilizing combination gas valves,

such as the VR800 series, the main gas cock is

built into the combination gas valve body. The

VR800 combination gas valve series is included

in models VR800A, VR850A, VR844M, and

VR852M.

MAIN GAS PRESSURE REGULATOR

The main gas pressure regulator is located in the

gas train, downstream from the main gas cock.

This regulator maintains the proper constant gas

pressure to the burners. It may be adjusted to the

correct pressure by removing the cap on top and

adjusting the slotted screw CLOCKWISE to

INCREASE the pressure or COUNTER-

CLOCKWISE to DECREASE the pressure for

separate regulators. On combination gas valves,

such as the VR800 series, this adjustment is

exactly opposite. Pressure adjustments should be

made with a U-tube manometer attached to the

burner manifold test port to ensure accuracy.

On boilers utilizing combination gas valves, such

as the VR800 series, the main gas pressure

regulator is built into the gas valve body.

Loading...

Loading...