Table 1 — Indoor-Air Filter Data*

UNIT TYPE OF FILTER QUANTITY...SIZE (in.)

581A

Fiberglass

Throwaway

4...20 x 20 x 2

4...16 x 20 x 2

579F†

Fiberglass

Throwaway

4...20 x 20 x 2

4...16 x 20 x 2

*When replacing filters, always use the same type and size originally

supplied.

†The 579F300 unit requires 2-in. industrial grade filters capable of hand-

ling face velocities of up to 625 ft/min (such as American Air Filter

no. 5700 or equivalent).

II. HEAT EXCHANGER

To ensure dependable and efficient heating operation, the heat

exchanger should be checked by a qualified maintenance per-

son before each heating season, and cleaned when necessary.

This checkout should not be attempted by anyone not having

the required expertise and equipment to do the job properly.

Checking and/or cleaning the heat exchanger involves remov-

ing the gas controls assembly and the flue collector box cover

and, when completed, reinstalling the gas controls assembly

for proper operation. Also, the flue collector box cover must

be replaced correctly so that a proper seal is maintained. Con-

tact your dealer for the required periodic maintenance.

III. EVAPORATOR-FAN MOTOR, CONDENSER-FAN MO-

TOR, FAN SHAFT BEARINGS, AND COMBUSTION FAN

MOTOR

Periodically check the condition of fan wheels and housings,

belt tension, and fan motor shaft bearings. No lubrication of

condenser or evaporator fan bearings or motors is required

or recommended for at least 5 years of normal operation.

After 5 years, motor life can be extended by having the mo-

tors serviced at an authorized motor service shop.

IV. COMPRESSOR

All compressors are factory shipped with a normal charge of

the correct type refrigeration grade oil in them and should

rarely require additional oil. The service technician must be

certain the proper oil level is maintained in the compressor

when it is installed and running.

V. EVAPORATOR AND CONDENSER COILS

Cleaning of the coils should only be done by qualified serv-

ice personnel. Contact your dealer for the required annual

maintenance.

VI. CONDENSATE DRAIN

The drain pan and condensate drain line should be checked

and cleaned at the same time the cooling coils are checked by

your dealer.

VII. CONDENSER FAN

WARNING:

Do not poke sticks, screwdrivers, or any

other object into revolving fan blades. Severe bodily in-

jury may result.

The fan must be kept free of all obstructions to ensure proper

cooling. Contact your dealer for any required service.

VIII. ELECTRICAL CONTROLS AND WIRING

Electrical controls are difficult to check without proper in-

strumentation; therefore, if there are any discrepancies in the

operating cycle, contact your dealer and request service.

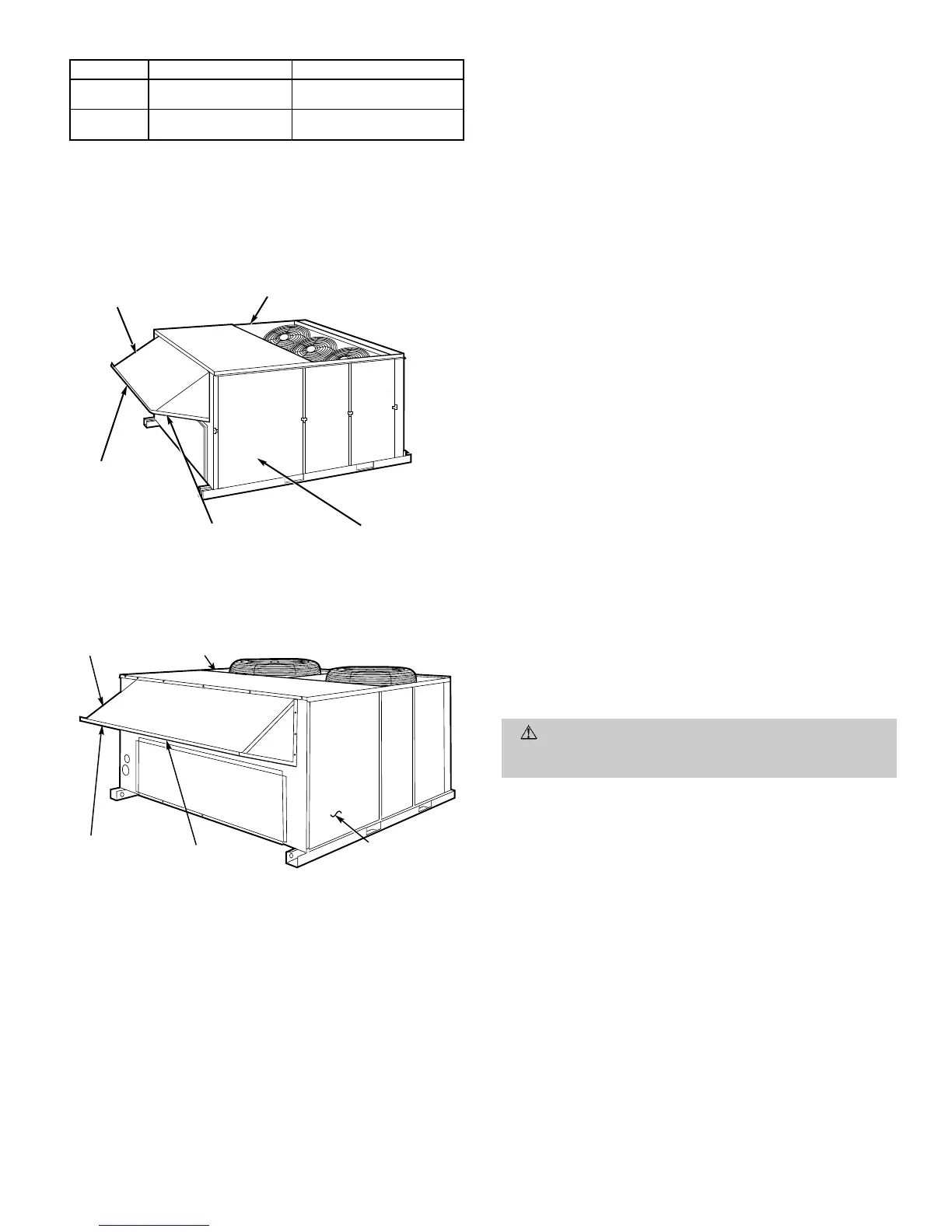

BURNER ACCESS

PANEL (HIDDEN)

HOOD

(OPTION)

OUTDOOR-AIR

FILTER

RETAINER

OUTDOOR-AIR

FILTERS

MOTORS AND FILTER

ACCESS PANEL

579F180,216 AND 581A155,180

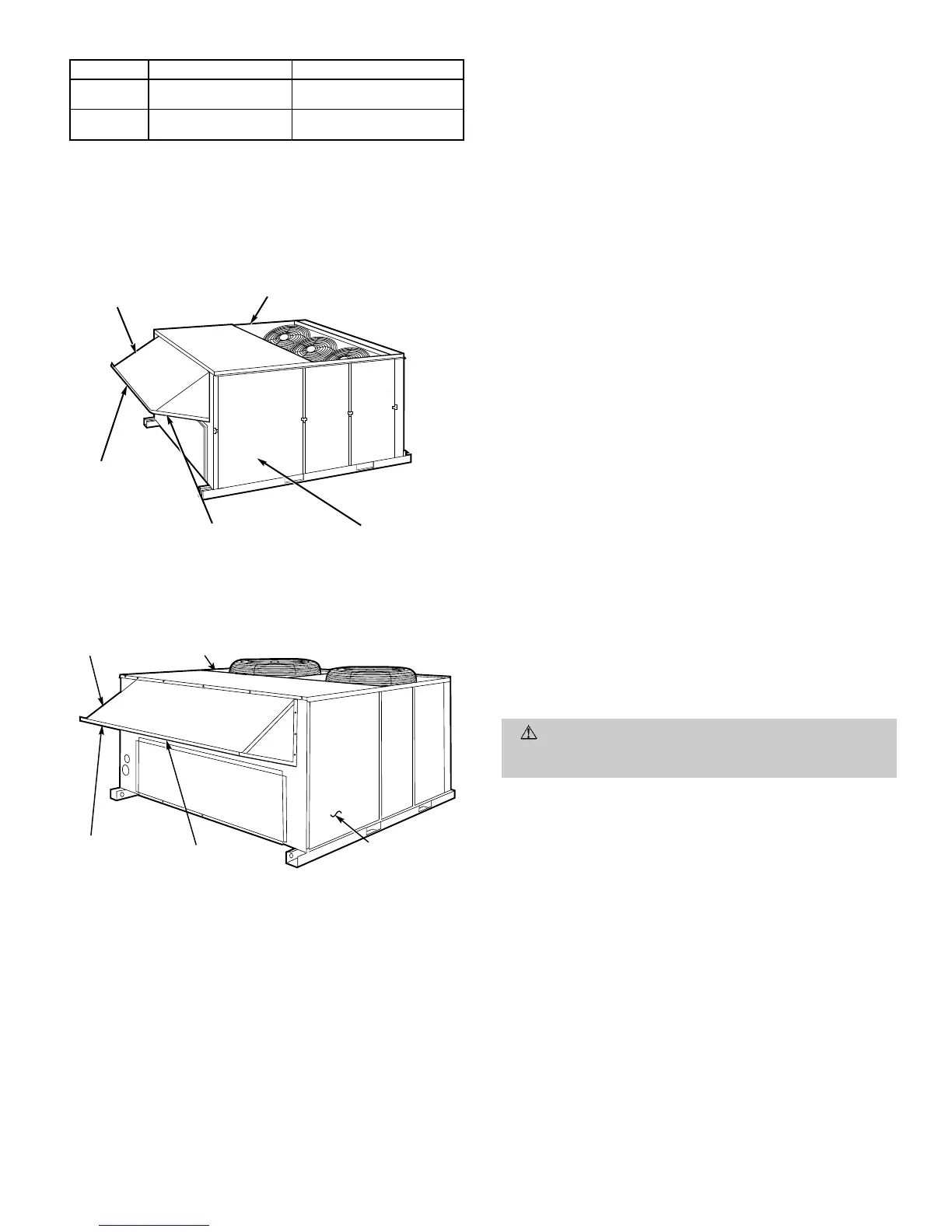

MOTOR AND

FILTER

ACCESS PANEL

HOOD

(OPTION)

BURNER ACCESS

PANEL (HIDDEN)

OUTDOOR-

AIR FILTERS

OUTDOOR-

AIR FILTER

RETAINER

579F240,300 AND 581A240

Fig. 4 — Filter Access Locations

—5—

Loading...

Loading...