7

3. Remove the left-side filter by tip-

ping the filter toward the center

and raising it from the V-shaped

channel in which it rests. (See

Fig. 24 and 25.)

4. Lower filter down next to the

blower and remove from furnace.

5. To remove the right-side filter,

lift from V-shaped channel and

remove through left-side the

same way as left-side filter.

6. Inspect the filter. If torn, replace

the filter.

7. Wash the filter (if dirty) in a sink,

bathtub, or outside with a garden

hose. Always use cold tap water. A

mild liquid detergent may be

used if necessary. Spray water

through the filter in opposite

direction of airflow through the

cross-mesh binding (when

present) side. Allow filter

to dry.

8. Reinstall clean filters with the

cross-mesh binding (when

present) side facing furnace

blower.

9. Replace blower access door and

secure with 2 screws. Turn on

electrical supply to the furnace.

(See Fig. 16.)

*Filters are factory provided with the

furnace. Filters may be field modified

by cutting and folding the frame as

indicated on the filter. Alternate

sizes and additional filters may be

ordered from your dealer.

COMBUSTION AREA

AND VENT SYSTEM

Inspect the combustion area and vent

system before each heating season.

An accumulation of dirt, soot, or rust

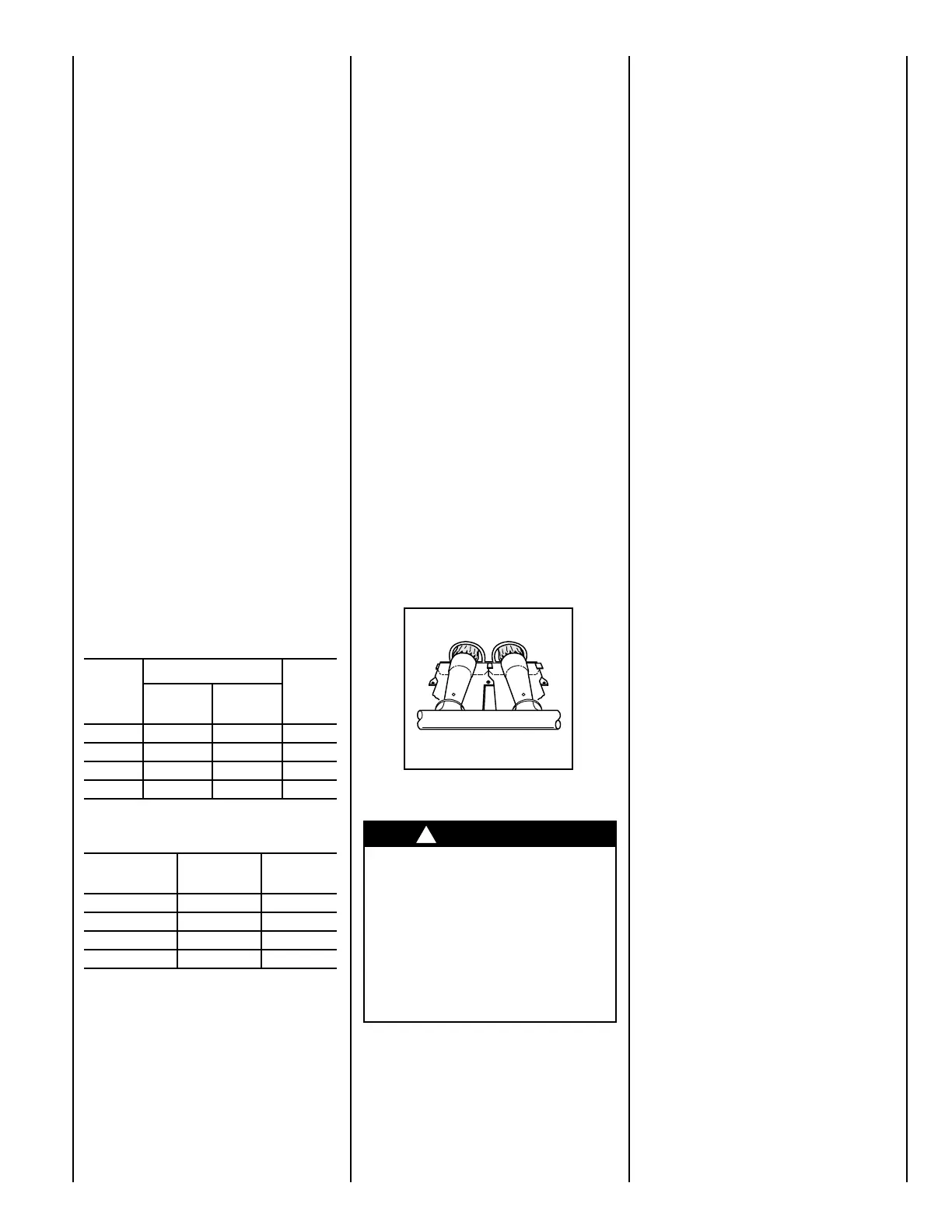

UPFLOW FURNACE

FILTER TABLE (IN.)

FURNACE

CASING

WIDTH

FILTER SIZE

FILTER

TYPESide Return

Bottom

Return

14-3/16 (1) 16 x 25 x 1* (1) 14 x 25 x 1 Cleanable

17-1/2 (1) 16 x 25 x 1* (1) 16 x 25 x 1 Cleanable

21 (1) 16 x 25 x 1 (1) 20 x 25 x 1* Cleanable

24-1/2 (2) 16 x 25 x 1* (2) 12 x 25 x 1 Cleanable

DOWNFLOW/HORIZONTAL

FURNACE FILTER TABLE (IN.)

FURNACE

CASING WIDTH

FILTER

SIZE

FILTER

TYPE

14-3/16 (2) 14 x 20 x 1* Cleanable

17-1/2 (2) 14 x 20 x 1* Cleanable

21 (2) 16 x 20 x 1* Cleanable

24-1/2 (2) 16 x 20 x 1* Cleanable

can mean a loss of efficiency and

improper performance. Buildups on

the main burners can cause faulty fir-

ing. This “delayed ignition’’ is charac-

terized by an alarmingly loud sound. If

your furnace makes a loud noise when

the main burners are ignited, shut

down the furnace and call your

servicing dealer.

Use your flashlight and follow these

steps for inspecting the combustion

area and vent system of your furnace:

1. Turn off the electrical supply to

furnace and remove the access

doors. (See Fig. 9, and 10 or 11.)

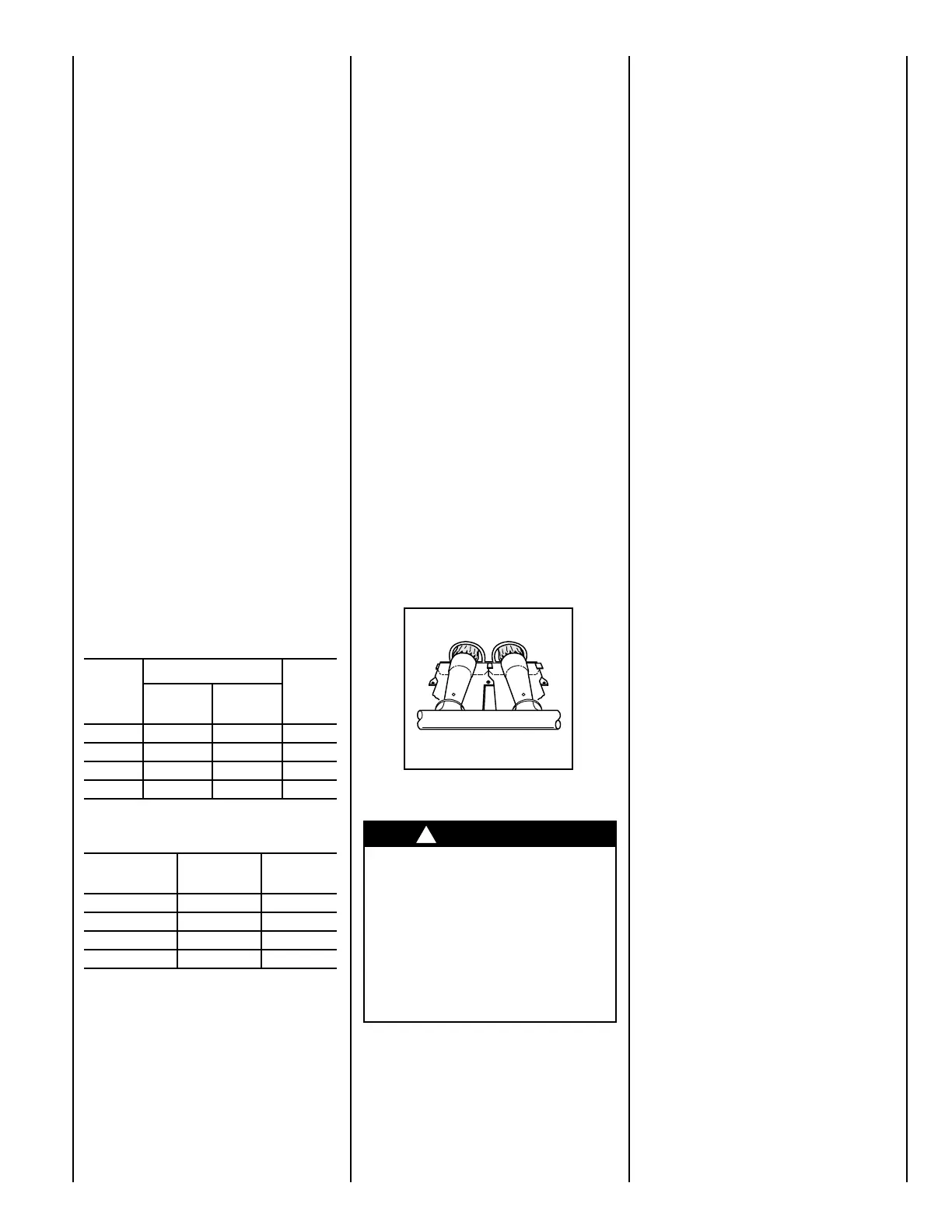

2. Carefully inspect the gas burner

for dirt, rust, or scale. (See Fig.

26.) Inspect the relief box, flue

connection area, and the vent pipe

for rust.

NOTE:

If dirt, rust, soot, or scale accu-

mulations are found, call your servic-

ing dealer. DO NOT OPERATE THE

FURNACE.

3. Inspect the vent pipe for a sag,

holes, or a disconnection. A hori-

zontal vent pipe must slope

upward. If rusty joints or seams,

or signs of water leakages are

found, call your dealer for service.

26

4. Replace the access doors and

restore electrical supply to the

furnace. Be sure bottom door

flange is inside of the furnace cas-

ing. (See Fig. 14 and 15.)

5. Start the furnace and observe its

operation. If possible, watch the

burner flames. Are they burning

WARNING

If holes are found or if the vent

pipe is obstructed or is not

connected, toxic fumes can es-

cape into your home. DO NOT

OPERATE YOUR FURNACE.

Call your dealer for service.

A failure to follow this warning

could result in personal injury

or death.

the air filter for dirt. Check for blocked

return-air or supply-air grilles. Be sure

they are open and unobstructed. If this

direction that the pipe runs (open)? Or is

it at a right angle to the pipe (closed)?

NOTE:

Before proceeding with the

next checks, turn off the electrical

power supply to the furnace. Remove

access doors.

• Is the control knob on the gas

valve turned to the ON position? If

this or the preceding check shows

an interruption in the gas supply,

make sure the gas has not been shut

off for safety reasons. If nothing else

seems to be wrong, follow the startup

procedures found on pages 4 and 5

of this booklet.

• If for some reason the vent is

blocked, the draft safeguard switch will

shut off the furnace. Reset the switch

by pushing the button located on top

of the switch. See page 2 or 3 for switch

location.

If the switch trips a second time, turn

off the furnace and call for service.

•

DOWNFLOW/HORIZONTAL

ONLY

—Check the manual reset aux-

iliary limit switch located on the blower

housing. If the blower motor fails, this

switch will shut off the furnace. Reset it

by pushing the button on the switch. If

it trips again, turn off the furnace and

call for service.

Loading...

Loading...