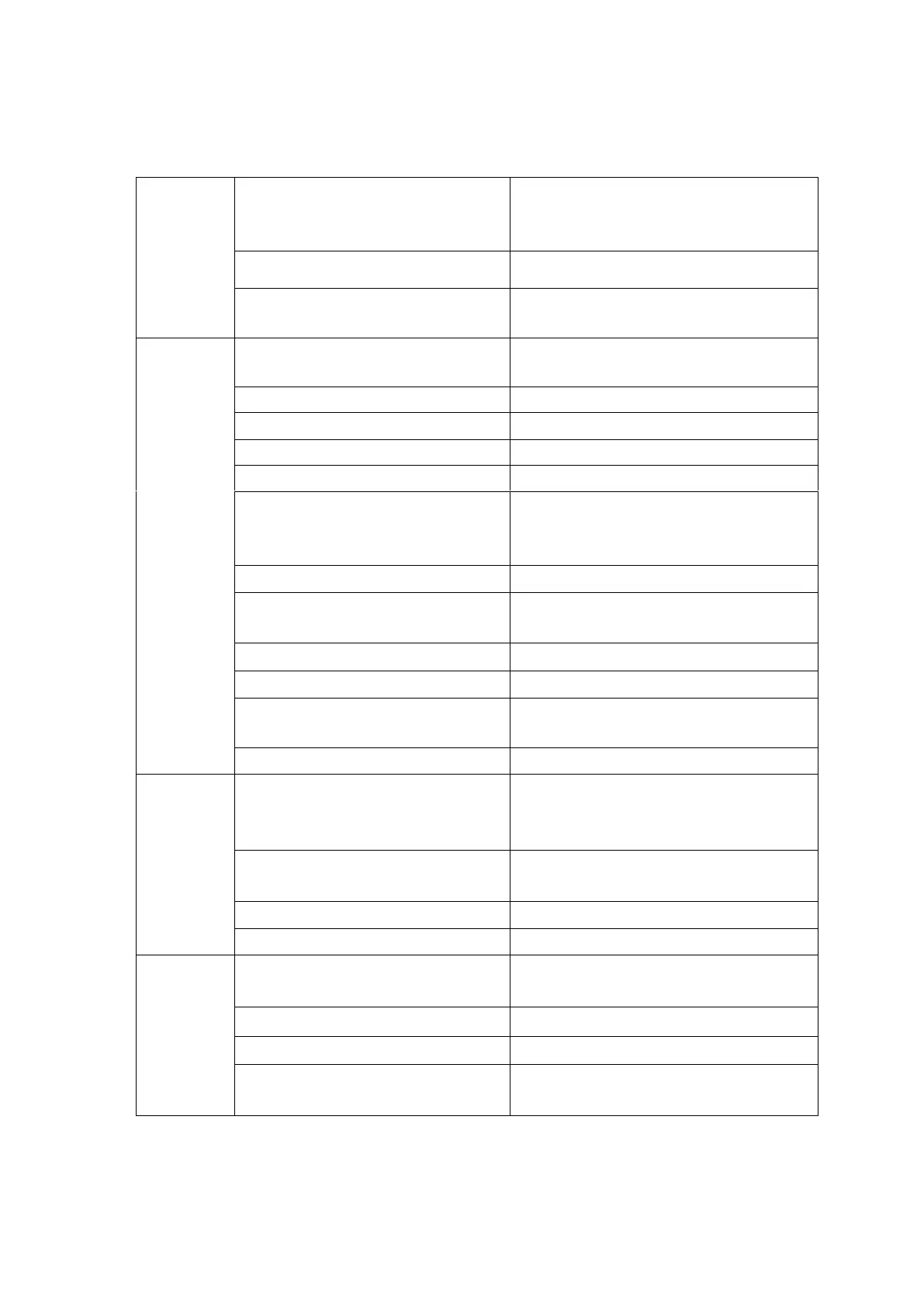

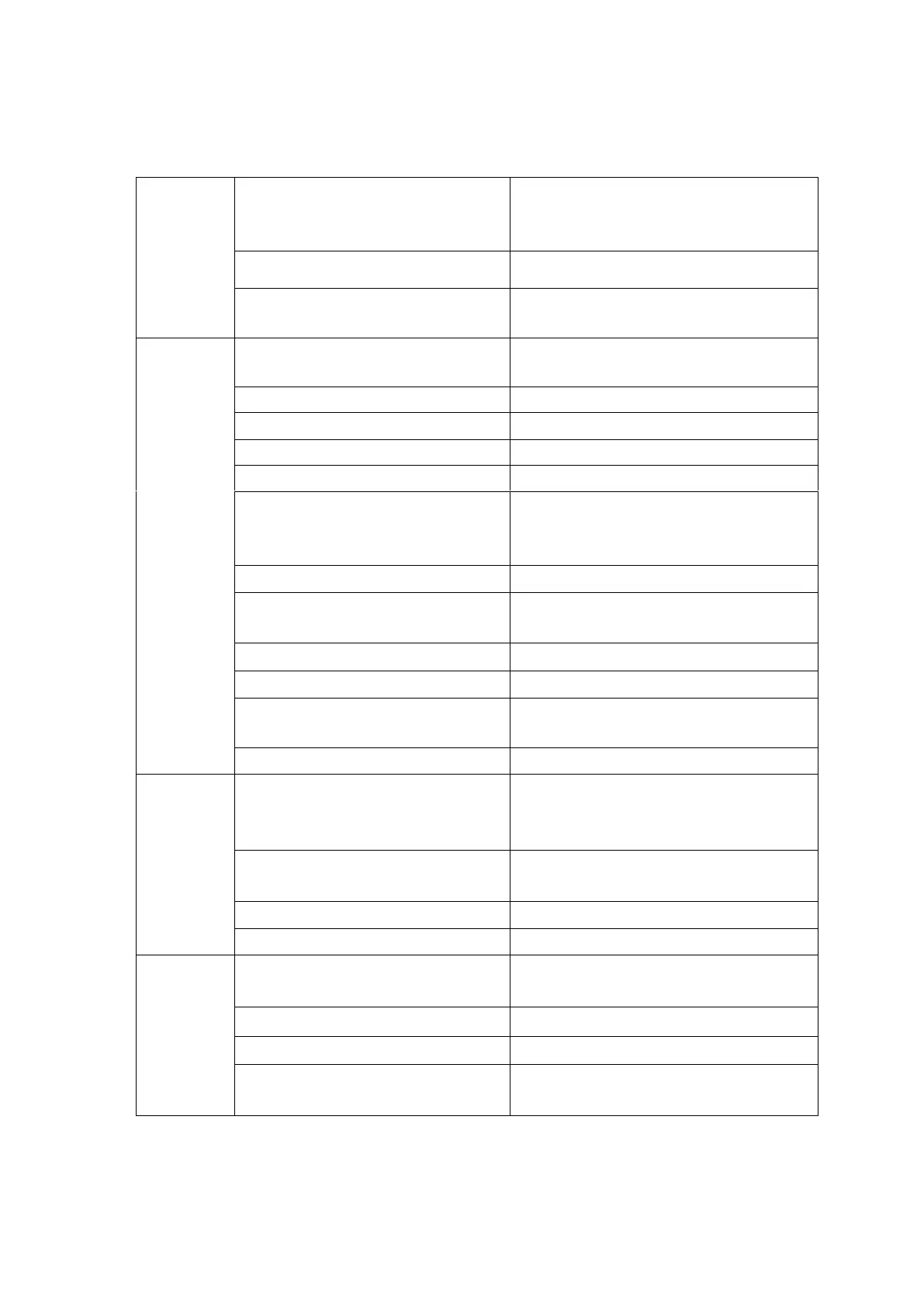

Keeping continuous operation under

high suction pressure

Pump surface temperature reaches 1 00℃on

continuous operation under high suction

pressure, no problem

Oil is under the MIN line of the oil

Add the specified amount of oil

Oil does not circulate, or the oil hole of

the cover is clogged

Overhaul and clean the oil hole

Abnormal

sound is

generated

Oil is not filled. Oil is under the MIN

line of the oil level

Overhaul (repacemer1tofthe cylinder, rotor

and cover)

a) The oil hole of the cover is clogged

b) Oil distributor valve has a trouble

b) Check and repair the oil distributor valve

Check the cooling fan mounting

Rattling sounds on starting or slopping

the pump

It’s a phenomenon caused by vanes that

temporarily make irregular motions, not a

particular problem

Motor rotation direction is reverse

Do the connection again to correct rotation

direction.

Coupling spider is damaged

Replace the coupling spider

Foreign matter has entered the pump

Disassemble and clean the pump to

eliminate foreign matter

Parts inside the pump are damaged

Overhaul(replace the damaged parts)

Lot of oil

splashed out

of the outlet

port

Pump oil excesses the specified

amount

Drain the oil until it gets the specified

amount

Continuous operation is performed at

a high evacuation pressure

install an oil mist trap at the outlet side

Clean or replace the oil mist trap

Exhaust valve plate is damaged

Replace the exhaust valve plate

The oil leak

s outside the

pump

Deterioration of the 0-ring and oil seal

of the case and cover

Check and replace the 0-ring and oil seal

Continuous operation is performed

Please select the heat-resisting

at a high evacuation pressure

The drain port is loose, the gasket is

damaged.

Tighten the drain port, replace the gasket

Note: Please refer to the related content in this manual to operate.

Loading...

Loading...