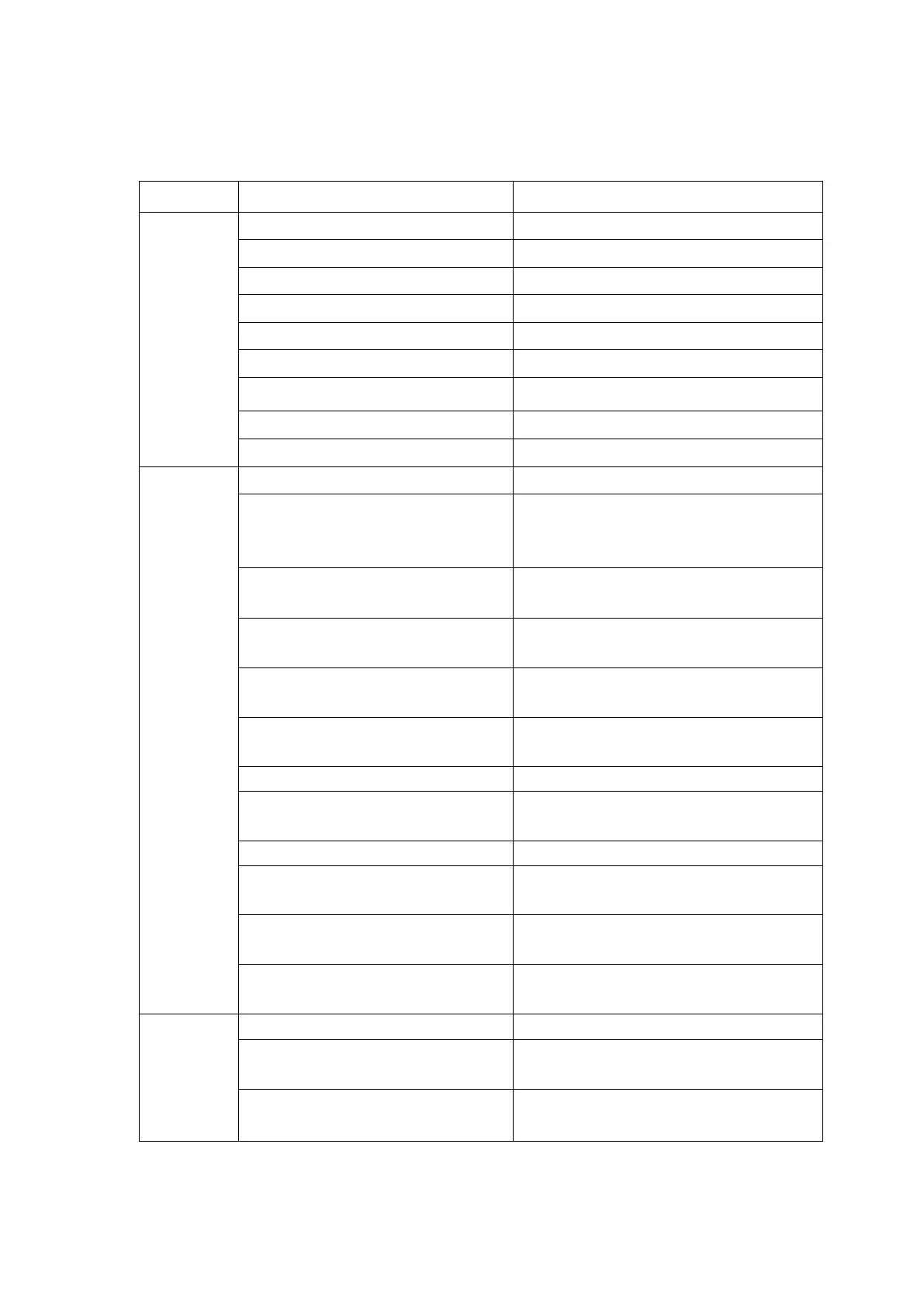

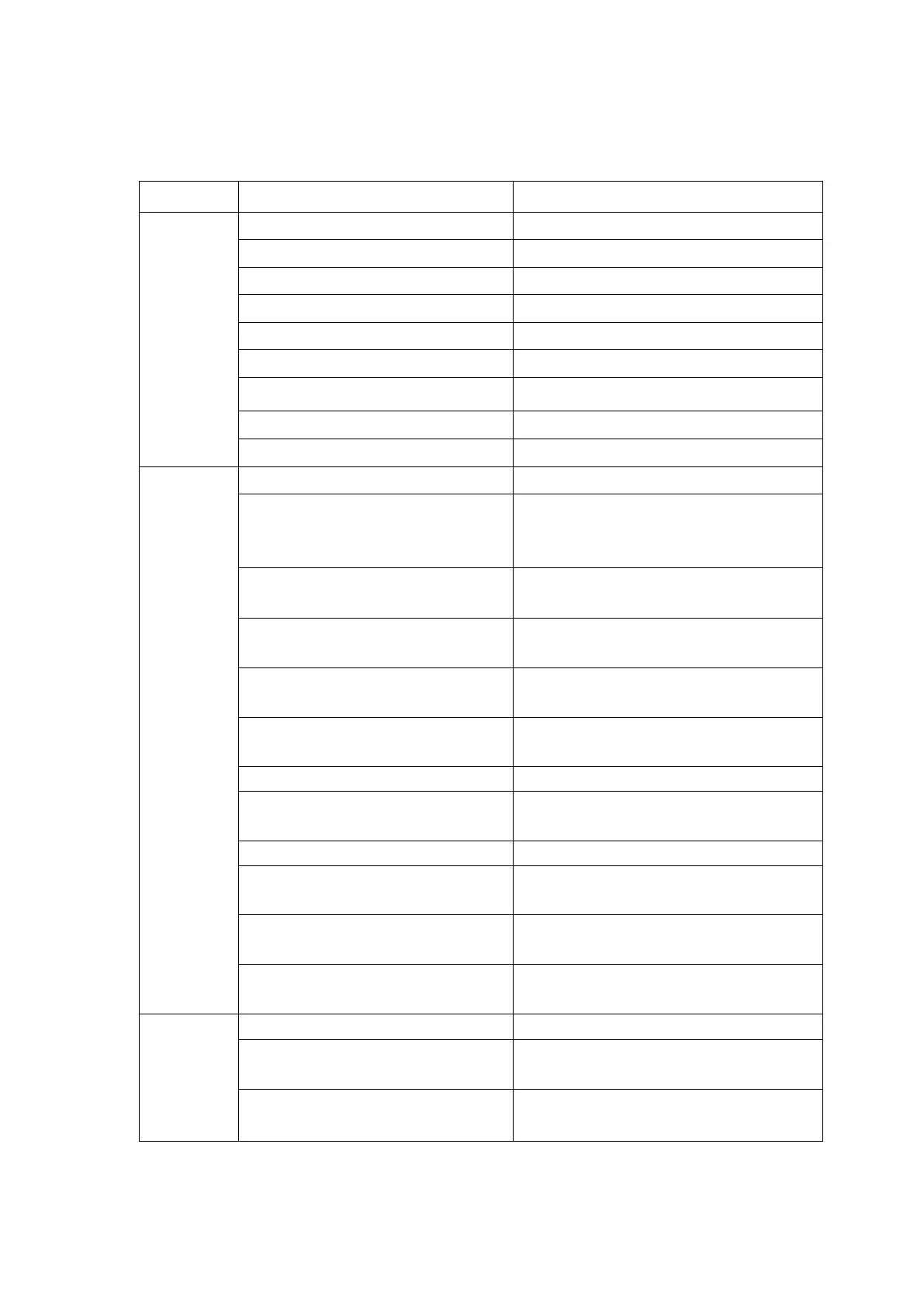

11 Trouble Check List

Table 7 Trouble Check List

Motor connection is wrong

Warm up or replace the pump oil

Exhaust filter or exhaust pipe is clogged

Clean exhaust filter or exhaust pipe

Problem with power supply voltage

Set the power supply voltage to within 10%

Parts inside the pump are damaged

Overhaul(replace the damaged part)

Pressure does

not come

down

Gas ballast valve is open

The pipe connected to the inlet port is

thin or connection distance is long

Connect a pipe wider than inlet diameter and

shorten the distance between the vacuum

chamber

Leakage occurs from the pipe connected

to the pump

Locate the leakage with a leak age detector

and stop the leak age

Metal mesh at the inlet port is clogged

Remove the pipe above the inlet and clean

the mesh

Specified oil is not being used

Overhaul the pump and replace the oil

specified by us

The oil is deteriorated or not supplied to

the specified volume

Replace the oil or add the oil to the specified

volume

a) Oil hole of the cover the like is

clogged

b) Oil distributor valve has a trouble

b) Check and repair the oil distributor valve

Pumping speed is too small to the

volume of the chamber

The pressure measurement method is

not correct

Measure the pressure correctly

The vacuum gauge is not suitable

Measure with a calibrated vacuum gauge

suitable for the pressure range

Pump surface

temperature

is abnormally

high

Area around the pump is enclosed

Make the ventilation available

The temperature of the evacuated gas is

high

Mount cooling equipment such as a gas

cooler at the inlet side

The environment temperature is high

Use pump in environment with air

conditioner

Loading...

Loading...