6 Operation

31 K-425 / K-436 Operation Manual, Version B

*

C

L

I

C

K

*

5

6

To Scrubber or

water jet pump

Example with two glass

caps installed!

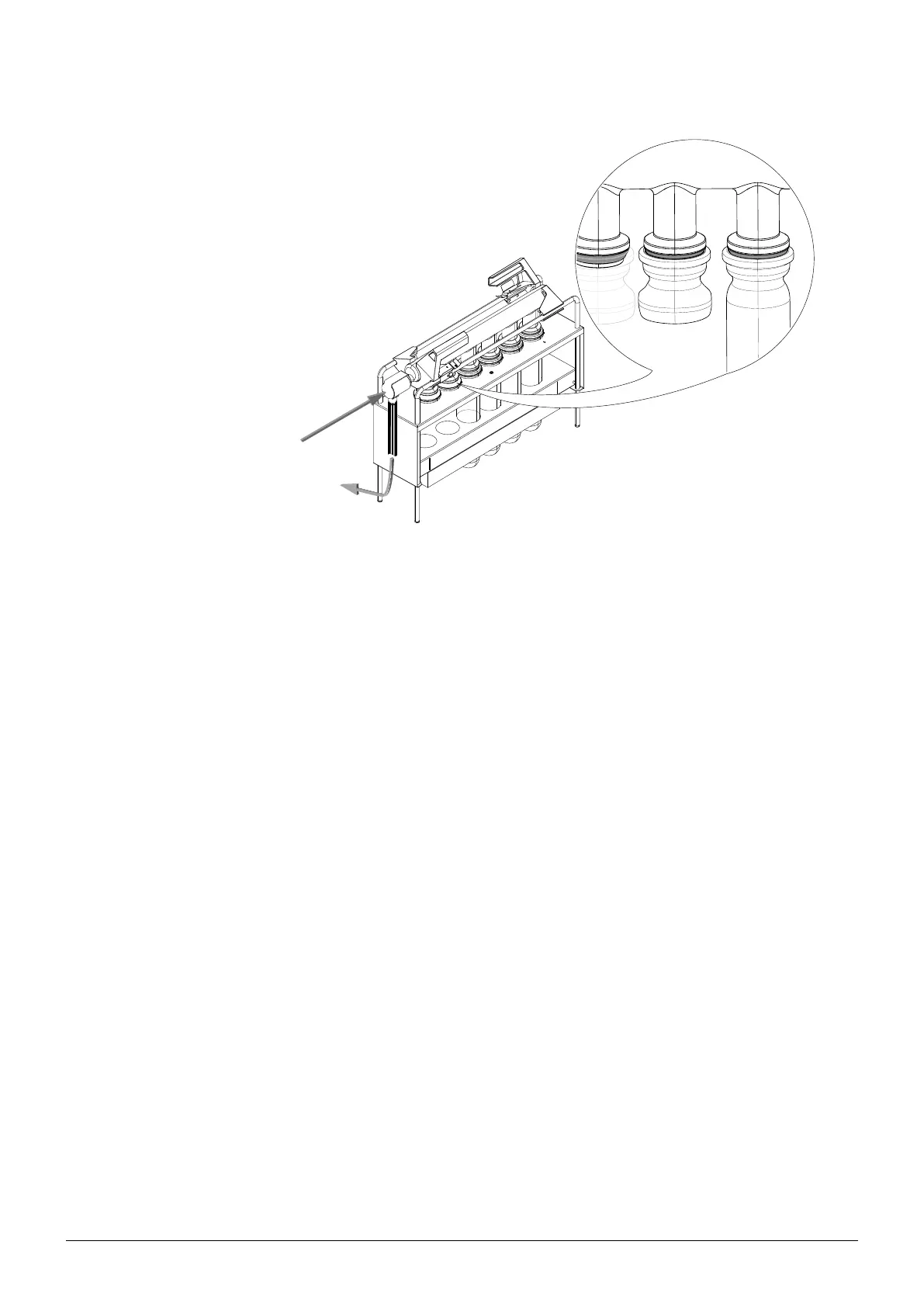

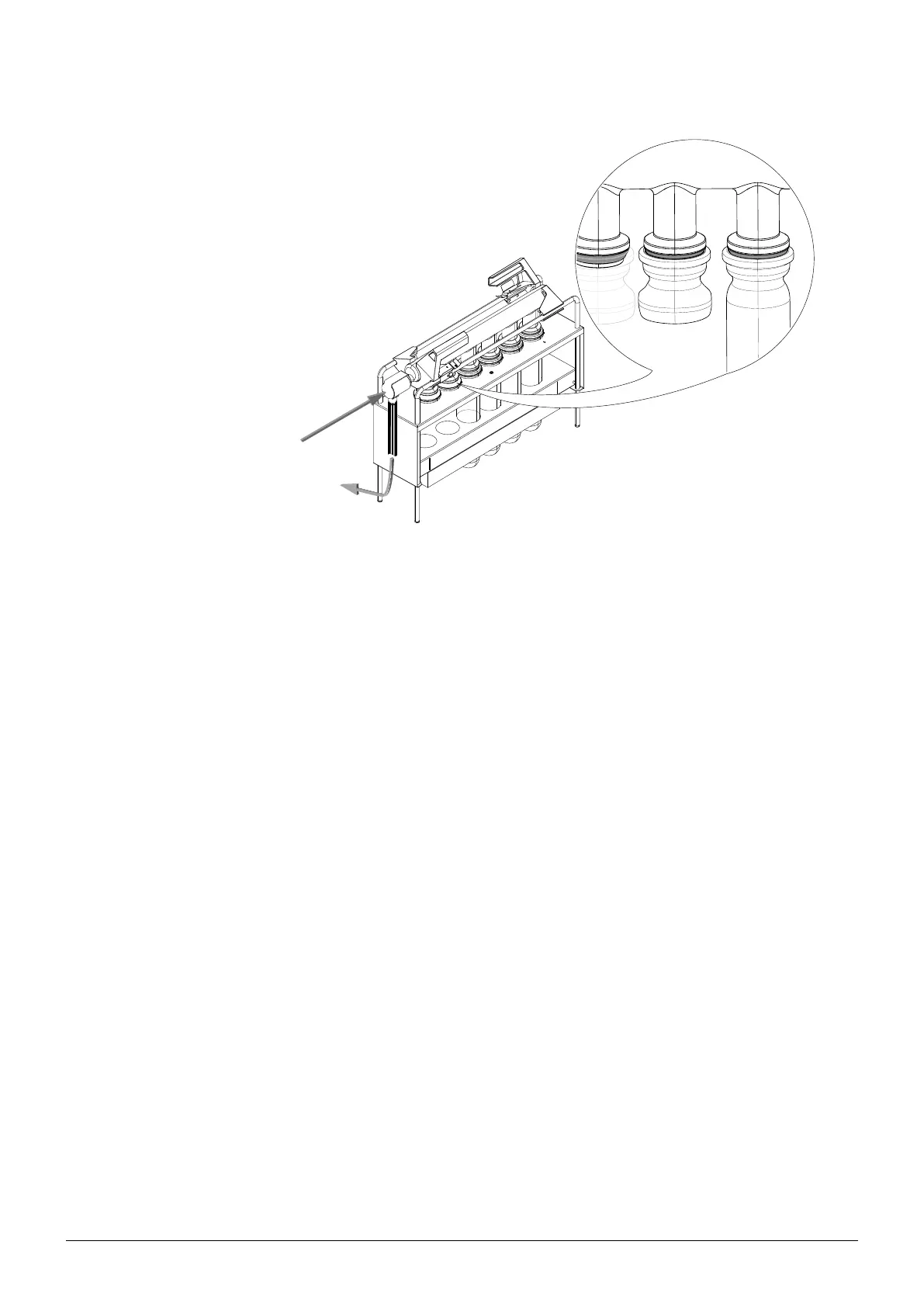

• Check for proper and tight seating of each rubber sealing 5.

➥ If necessary unlock the handles again and readjust the suction module!

• Plug the suction hose with plug onto the suction module 6.

➥ The plug catches with a noticable *click* sound.

• If applicable, follow the previous steps to install a suction module on a second rack.

• Switch on the Scrubber or water jet pump and activate the fume hood ventilation.

➡The rack(s) can now safely be processed in the SpeedDigester.

Note

• Clean all glass parts before mounting to avoid cross contamination.

• When a water jet pump is used, hazardous vapours can escape into the environmental air if the

suction is inadequate.

• If a Scrubber without condensation step is used, the condensate that accrues must be absorbed

by means of a Woulff bottle between the SpeedDigester K-425 / K-436 and the Scrubber.

• When operating with 3rd party sample tubes no insulation caps and glass caps are available. In

this case, all positions must be equipped with samples!

Loading...

Loading...