15

DP12VL

OPERATING INSTRUCTIONS

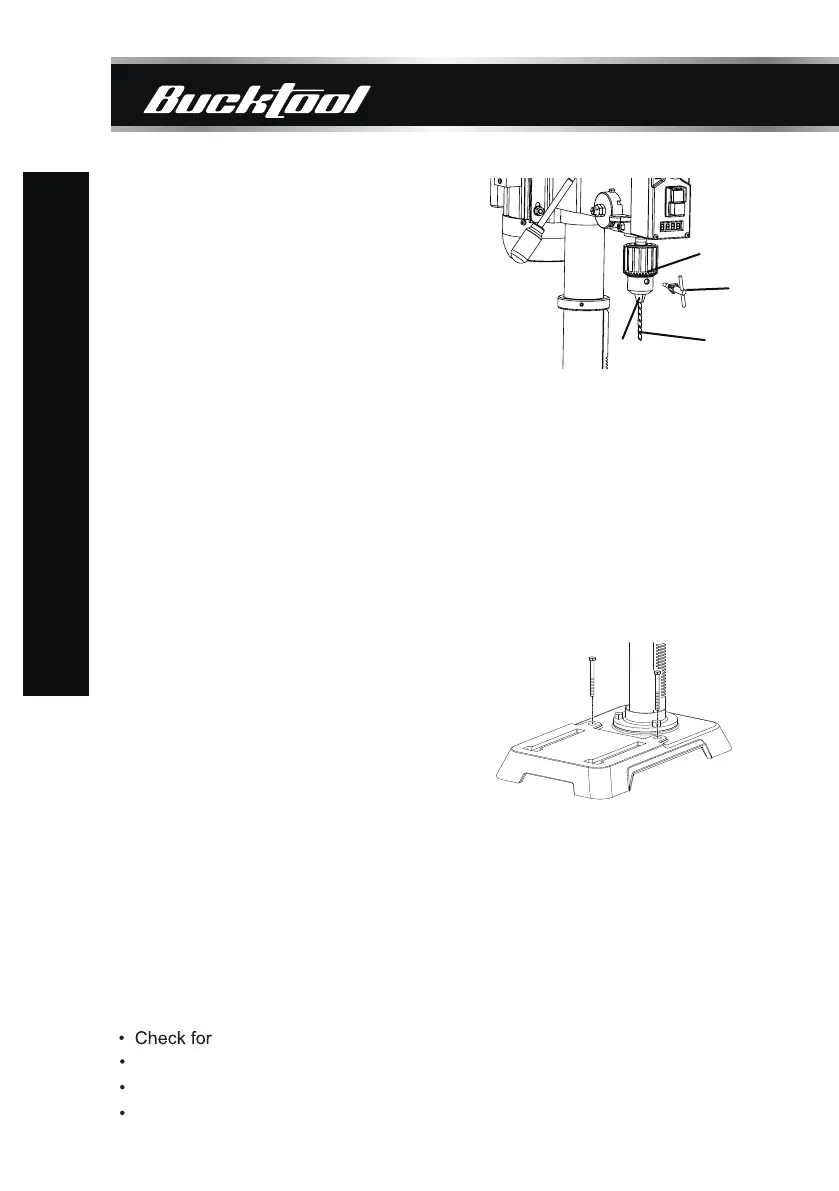

MOUNTING THE DRILL PRESS

If the drillpss is to be used in a permanent location secu it to a workbench or other

stable surface.

If the drill press is to be used as a portable t

ool,fasten it permanently to a mounting

board that can easily be clamped to a

workbench or other stable surface.The

mounting board should be of sufficient

size to avoid tipping while drill press

is in use. Any good grade plywood or

chipboarwith a 3/4

in. t

hi

ckness is

recommended.

1. Mark holes on surface where drill

press is to be mounted using holes

in drill press base as a template for

hole pattern.

2. Drill holes through mounting su

rface.

3. Place drill press on mounting surface ,

aligning holes in the base with holes drilled in the mounling surface.

4. Insert bolts (not included) and tighten

securely with lock washers and hex

nuts (not included).

5. If lag bolts are used,make sure they are long enough to go through holes

in drill press base and material the

drill press is being mounted to. If

machine bolts are used make sure bolts are long enough to go through holes

in drill press,the material being mounted to,and the lock washers and hex nuts.

NOTE: AII bolts should be inserted from the top. Install the lock washers and hex

nuts from the underside of the workbench.

Once the drill press is secureIy mounted

on a sturdy surface:

vibration when the motor is switched ON.

Adjust andretighten the mounting

hardware as necessary.

Check to assure that the spindle shaft

Check the table assembly to assure smooth movement up and down the column.

moves smoothly.

INSTALLING A DRILL BIT

1. Place the chuck key (1) into the side keyhole

of the chuck (2), meshing the key with the

gear teeth.

2. Turn the chuck key counterclockwise to open

the chuck jaws (3).

3. Insert a drill bit (4) into the chuck far enough

to obtain the maximum grip of the chuck jaws

on the bit shank.

4. Center the drill bit in the chuck jaws before the final tightening of the chuck.

5. Tighten the chuck jaws using the chuck key to ensure that the drill bit will not slip

while drilling. Tighten all three keyholes on the chuck.

6. Remove the chuck key and place it back on the onboard storage.

1

4

3

2

Loading...

Loading...