20

DP12VL

21

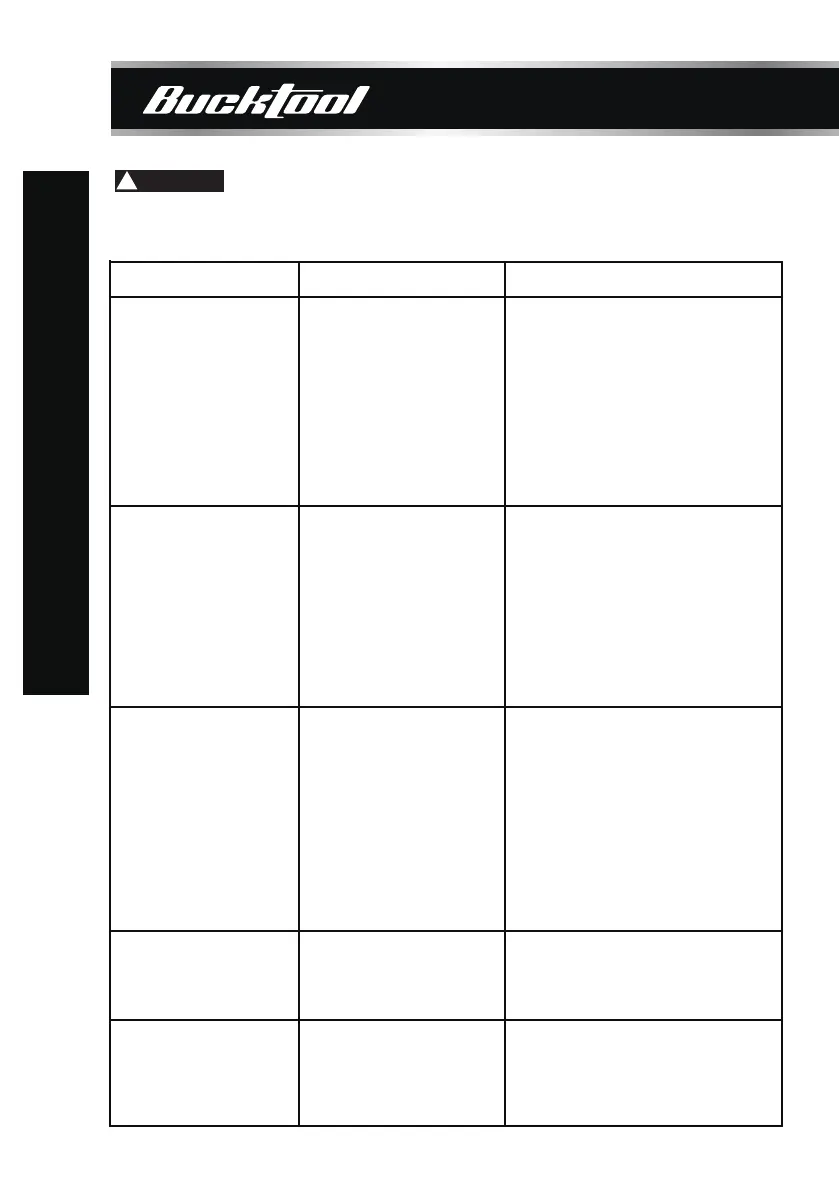

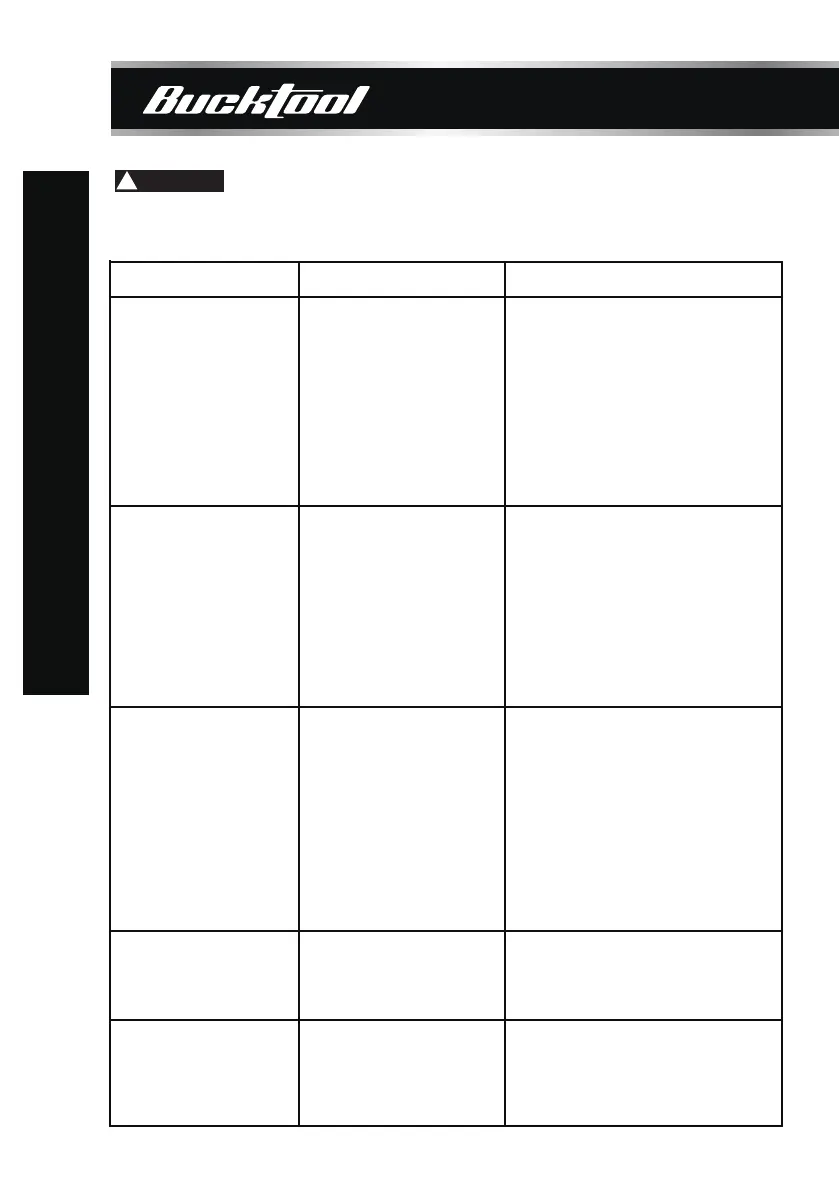

TROUBLESHOOTING

To avoid injury from an accidental start, turn the switch OFF and always remove the plug from

the power source before making any adjustments.

WARNING

!

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Noisy operation

or excessive

vibration

1) Incorrect belt tension

2) Dry spindle

3) Loose spindle pulley

4) Loose motor pulley

5) Seized motor pulley

1) Adjust the belt tension.

2) Lubricate the spindle.

3) Tighten the set screws on the

side of the spindle pulley.

4) Tighten the set screws on the

side of the motor pulley.

5) Lubricate motor pulley and motor

shaft; ensure that pulley opens and

closes when machine is ON and

speed is adjusted.

The drill bit burns

or smokes

Excessive drill

run out or

wobble; drilled

hole is not round

1) Drilling at the incorrect

speed

2) The wood chips are not

coming out of the hole

3) Dull drill bit

4) Feeding the workpiece

too slowly

5) Not lubricated

1) Bent drill bit

2) Bit improperly installed

in the chuck

3) Worn spindle bearings

4) Lengths of cutting flutes

or angles not appropriate

for the hardness of the

wood grain

5) Chuck not properly

installed

1) Replace the drill bit.

2) Reinstall the bit.

3) Bearings may need replacement.

4) Resharpen the drill bit correctly

or replace with the appropriate type.

5) Reinstall the chuck.

1) Change the speed.

2) Retract the drill bit frequently to

clear the chips.

3) Resharpen or replace the drill bit.

4) Feed fast enough to cut the

workpiece.

5) Lubricate the drill bit with cutting

oil or motor oil.

Drill bit binds in

the workpiece

Spindle returns

too slowly or too

quickly

1) The workpiece is

pinching the bit

2) Excessive feed

pressure

Coil spring has improper

tension

Adjust the coil spring tension.

1) Support or clamp the

workpiece.

2) Feed more slowly.

Loading...

Loading...