Troubleshooting

WARNING_ab

Risk of electrical shock, risk of damage to equipment.

Electrical installation work must only be executed by qualified personnel that knows and observes the following regulations:

- IEC 364 or CENELEC HD 384 or DIN VDE 0100, respectively,

- IEC-Report 664 or DIN VDE 0110,

- BGV A2 (VBG 4) or equivalent national accident prevention regulation.

CAUTION_ac

During operation the surface of the compressor may reach temperatures of more than 70 °C.

Risk of burns!

Let the compressor cool down prior to a required contact or wear heat protection gloves.

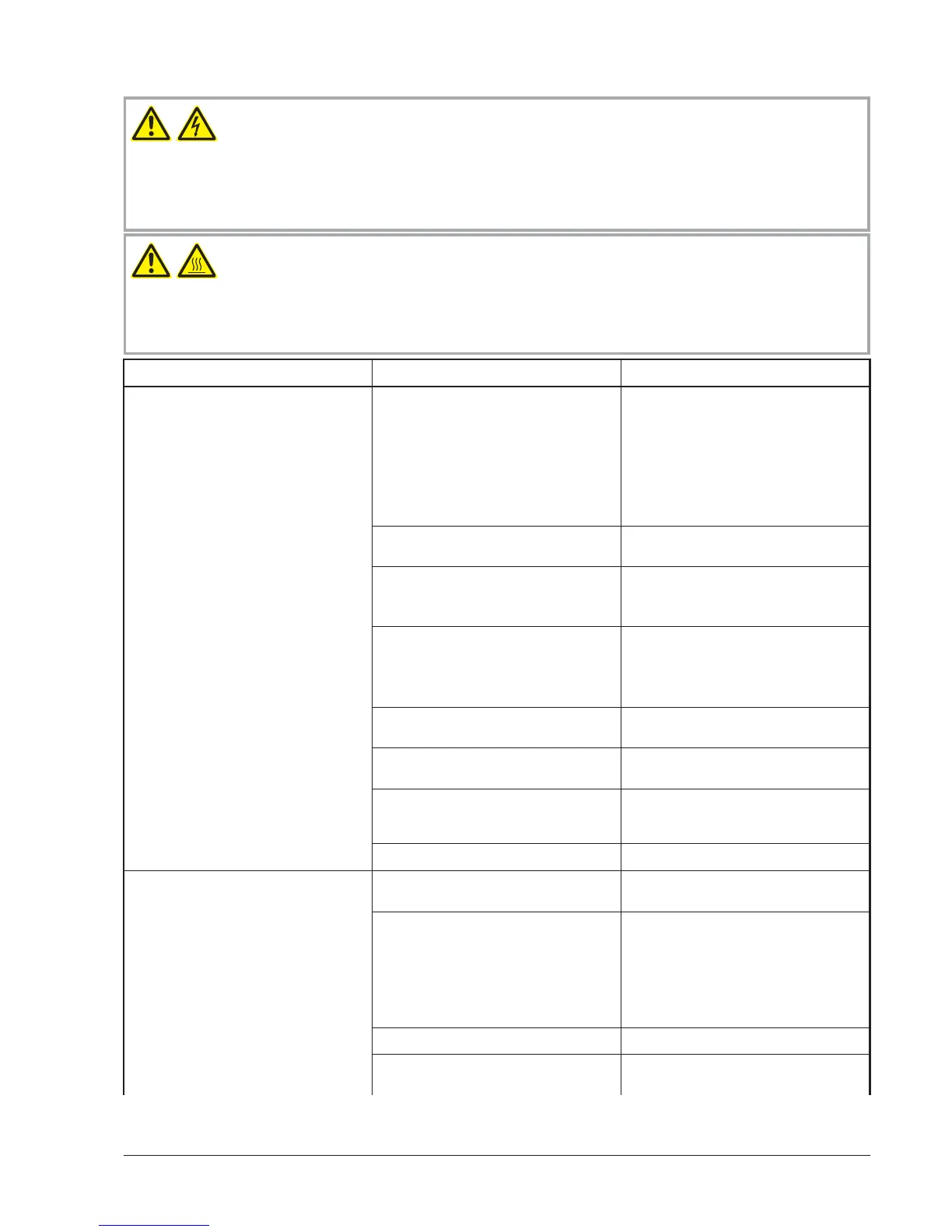

Problem Possible Cause Remedy

The compressor does not reach the usual pres-

sure

The drive motor draws a too high current

(compare with initial value after commission-

ing)

Filling the system takes too long

Building up pressure in the system takes too

long

The pressure system or pressure line is not

leak-tight

Check the hose or pipe connections for possi-

ble leak

The pressure relief valve/regulating system is

misadjusted or defective

Adjust, repair or replace, respectively

The screen (715) in the gas inlet (b) is partially

clogged

Clean the screen (715)

If cleaning is required too frequently install a

filter upstream

In case a filter (b) is installed on the gas inlet

(b):

The filter (b) on the gas inlet (b) is partially

clogged

Clean or replace the inlet air filter (b), respec-

tively

Partial clogging in the suction, discharge or

pressure line

Remove the clogging

Long suction, discharge or pressure line with

too small diameter

Use larger diameter

The valve disk of the inlet non-return valve is

stuck in closed or partially open position

Disassemble the inlet, clean the screen (715)

and the valve (714) as required and reassem-

ble

Internal parts are worn or damaged Repair the compressor (Busch service)

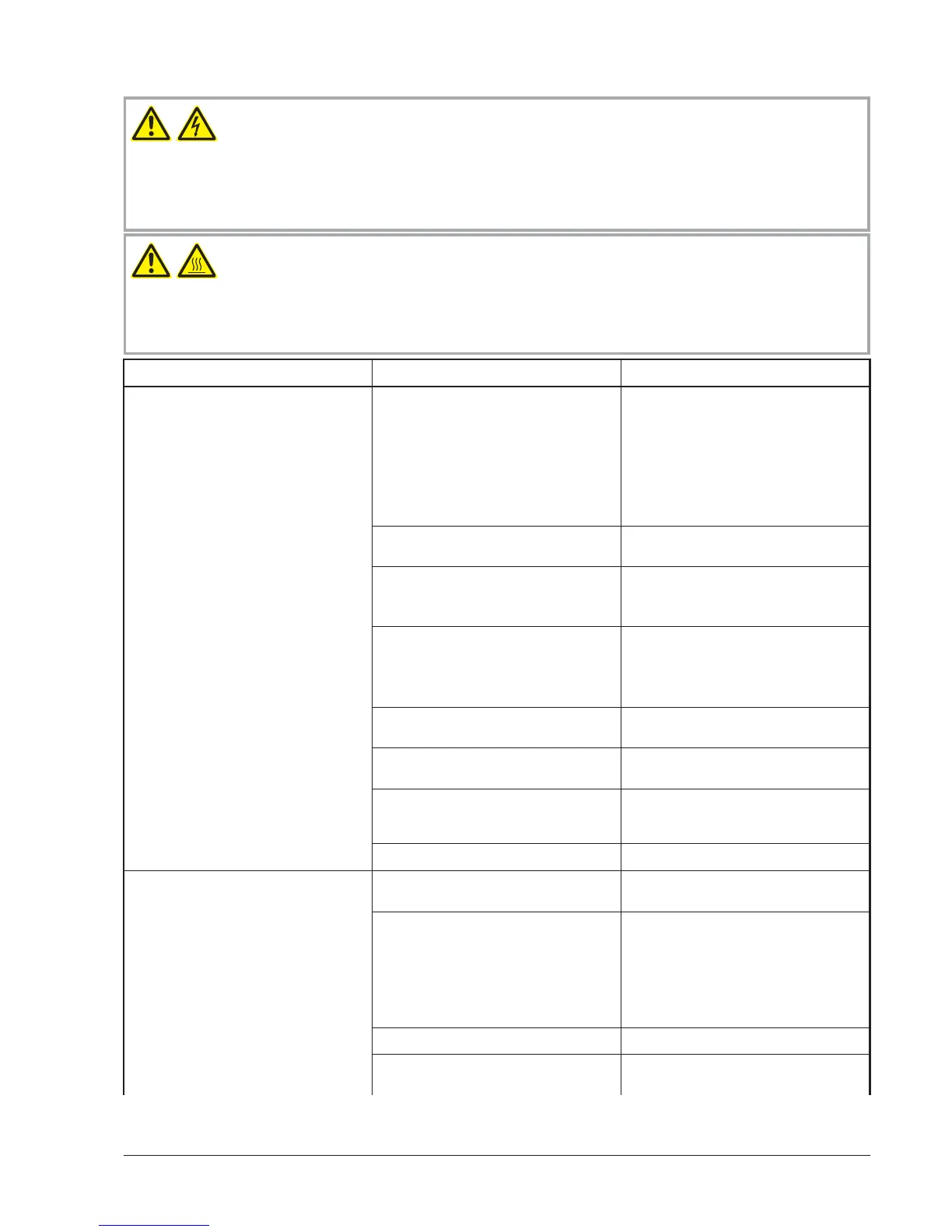

The compressor does not start The drive motor is not supplied with the cor-

rect voltage or is overloaded

Supply the drive motor with the correct volt-

age

The drive motor starter overload protection is

too small or trip level is too low

Compare the trip level of the drive motor

starter overload protection with the data on

the nameplate, correct if necessary

In case of high ambient temperature: set the

trip level of the drive motor starter overload

protection 5 percent above the nominal drive

motor current

One of the fuses has blown Check the fuses

The connection cable is too small or too long

causing a voltage drop at the compressor

Use sufficiently dimensioned cable

MI 1502 BP Troubleshooting

0870152627 / 101117 page 9

Loading...

Loading...