Capital Automotive Equipment

Model:4PG8000

and the power unit mounting plate on the Power Side post, using four M8 hex head bolts and nuts

supplied.

11. According to the hydraulic layout diagram, connect the oil pipes.

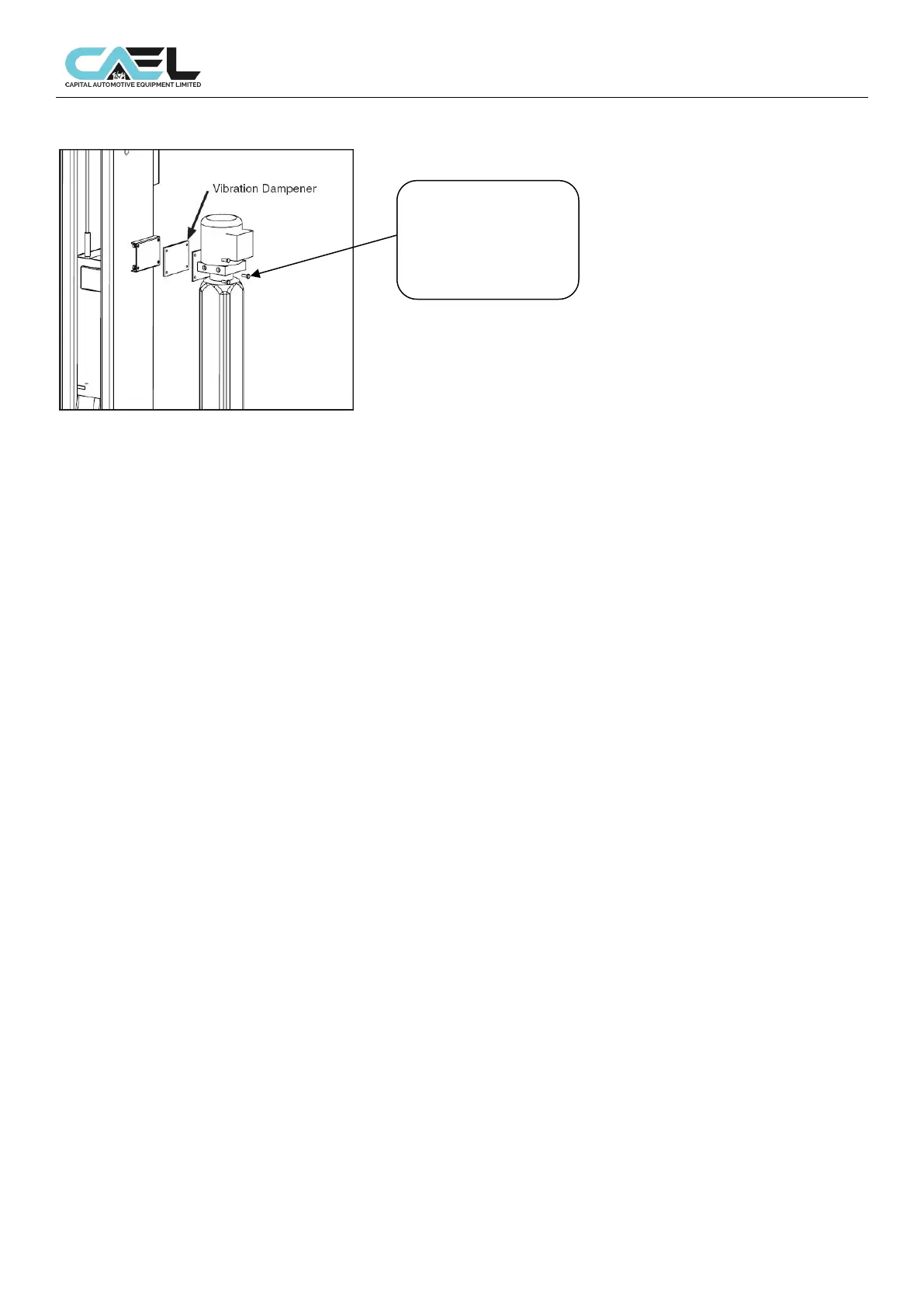

• Attach the power unit onto the support mounted on the power side column and secured with included

screws and washers.

• Route the hydraulic hoses referring the below photo.

• Tighten the fittings thoroughly.

Warning: When routing the hose, make sure to fit clips in the central position to keep the hose off the

moving steel cables under the base plate. Make sure to keep the hoses clean from dust.

12. Installation of limit switch

Fix the limit switch onto the power-side column in the position as shown in the figure 14 by using the

supplied screws.

And limit switch cable and motor cable are in parallel connection.

Raise the lift at a height of 70.8” (1800mm) to check for the proper function;

If the switch is not functioned properly, adjust the position of the switch lever

Chapter 5 Adjustment

5.1 Preparation before adjustment

Upright adjustment:

Use plumb to fix the top of post and check whether its install position is upright.

Then hammer the expanded bolt and tighten the ground bolt cap.

Only can hammer the expanded bolt after the expired period of the concrete and the gap between base

plate and ground surface must be filled with iron plate or concrete and then tighten the anchor bolts!

5.2 Process of adjustment

• Check whether the connection of power is correct, pay attention to the turning of 1 phase motor.

• Ensure all bolts are tightened enough.

• Press and HOLD “UP” button on motor, it will go up.

Press UP button on motor, the platform will go up 1 or 2 inch and lock latches leave the lock block, and

press and hold LOCK RELEAE HANDLE, then

Pull the LOWERING HANDLE on the power unit until the lift

has descended completely.

•

M8 x1.25 x 35mm

hex head bolts, M8

flat washers and

M8 Nylock nuts

Loading...

Loading...