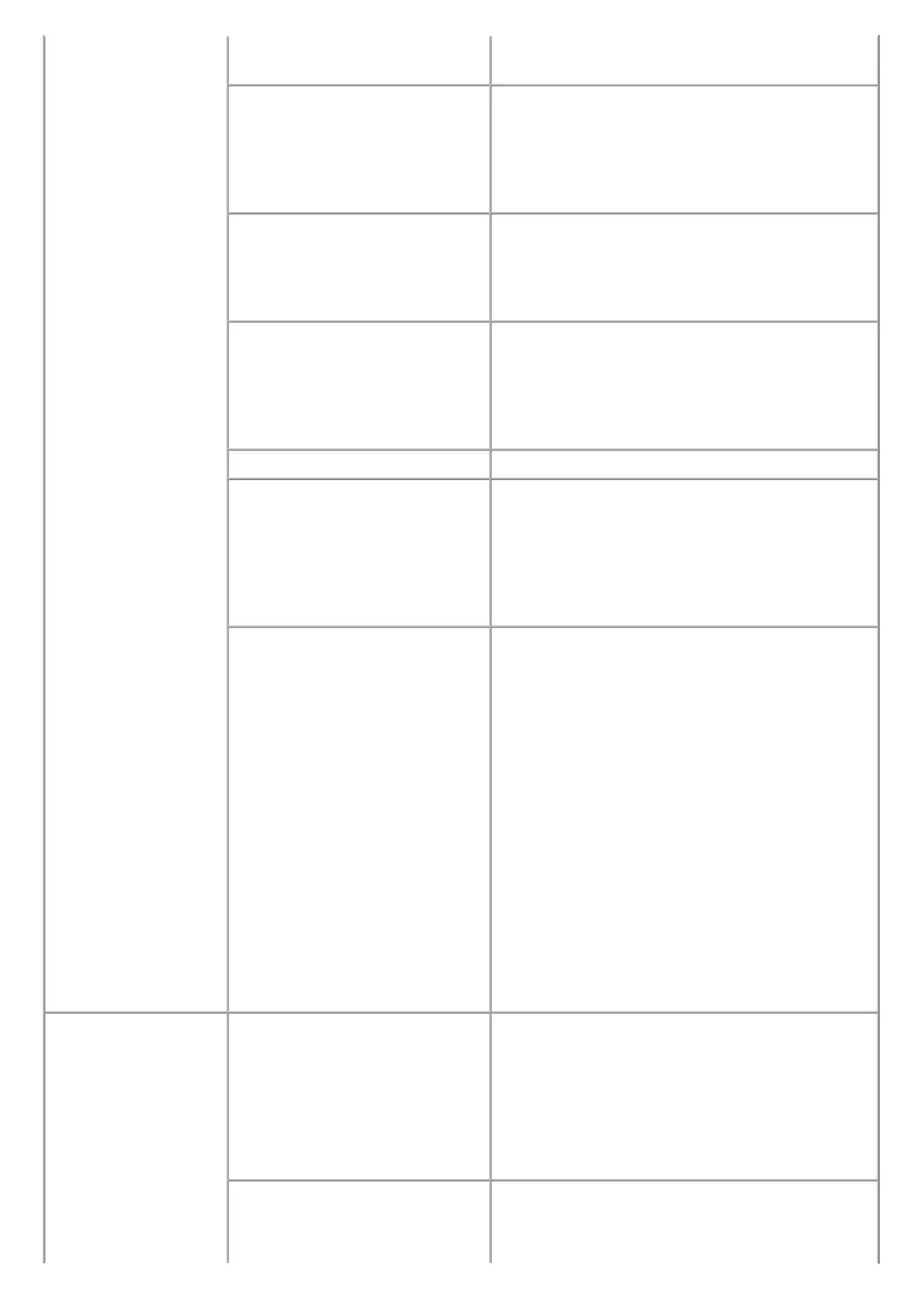

- Clean the paper path with a cotton swab or cloth.

- Clean the paper feed rollers.

The back side of paper gets smeared. - Clean the platen rib (clean the paper path with a cotton

swab or cloth).

- Confirm that the platen ink absorber fits in place

properly.

- Confirm that the paper eject rollers are free from ink

smear.

A part of a line is missing on printouts. - Perform nozzle check pattern printing, and confirm that

ink is properly ejected from all the nozzles.

- Replace the

- ink tank, or

- print head

*1

.

Color hue is incorrect. - Confirm that the ink tanks are installed properly.

- Perform print head maintenance.

- Replace the

- ink tank, or

- print head

*1

- Perform print head alignment.

Printing is incorrect. Replace the logic board.

No ejection of black ink. - Confirm that the ink tanks are installed properly.

- Perform print head maintenance.

- Replace the

- ink tank, or

- print head

*1

.

- Remove foreign material from the purge unit caps, if any.

- Replace the purge unit.

Graphic or text is enlarged on printouts.

When enlarged in the carriage movement direction:

- Clean grease or oil off the timing slit strip film.

- Replace the

- timing slit strip film,

- carriage unit,

- logic board, or

- scanning unit (when copying)

When enlarged in the paper feed direction:

- Clean grease or oil off the timing slit disk film or the

timing slit disk eject film.

- Replace the

- timing slit disk film,

- timing slit disk eject film,

- timing sensor unit,

- LF roller,

- platen unit,

- logic board, or

- scanning unit (when copying)

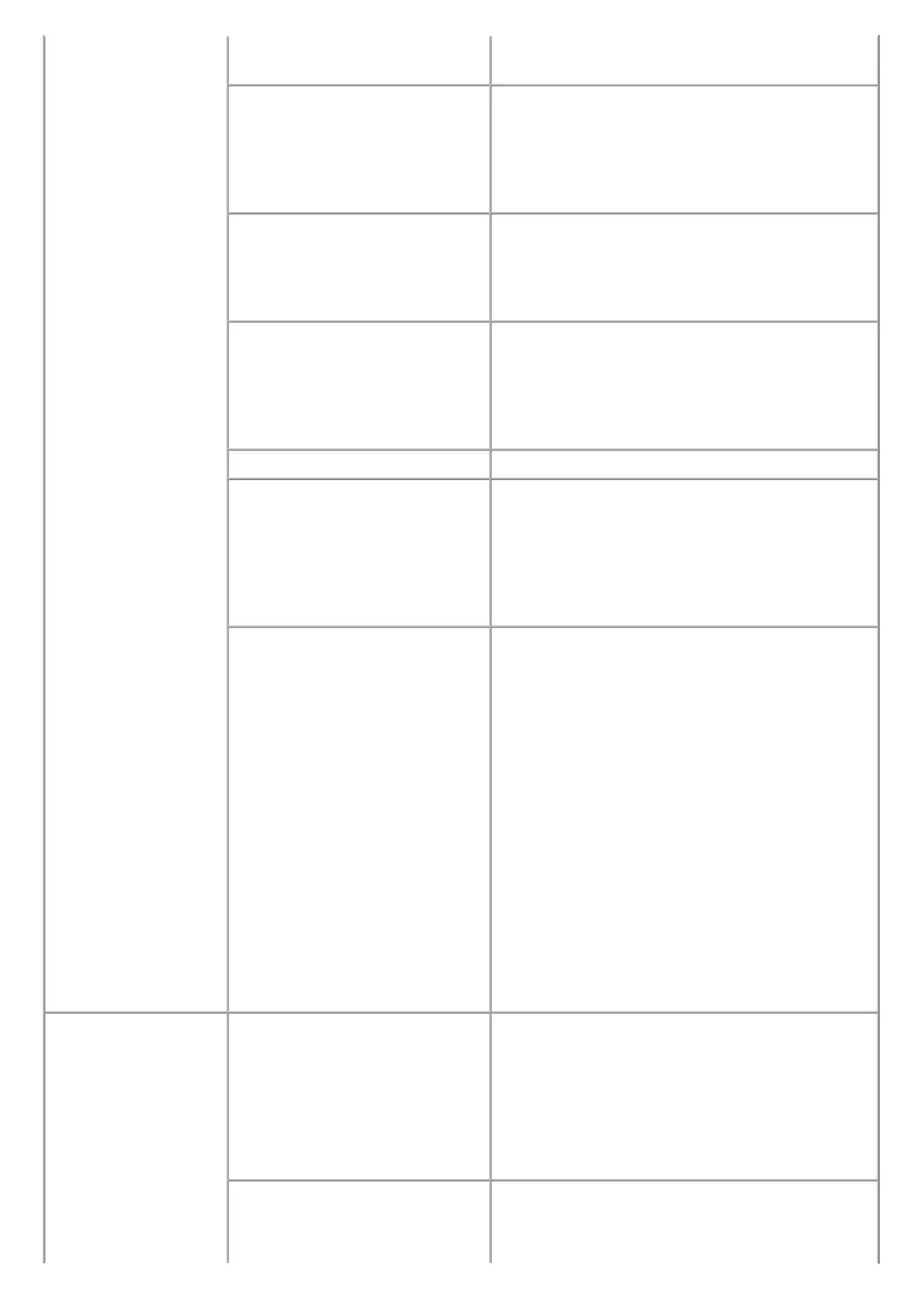

Faulty scanning No scanning. - Confirm the connection between the scanning unit and

the logic board.

- Replace the

- scanning unit, or

- logic board.

- Confirm that the driver software is installed properly.

- Confirm that the USB cable is connected properly.

- Confirm the light of the FAU lamp.

Streaks or smears on the scanned

image.

- Clean the platen glass.

- Confirm the connection between the scanning unit and

the logic board.

Loading...

Loading...