*1: Only for CD / DVD printing supported regions.

(2) Periodic maintenance

No periodic maintenance is necessary.

(3) Periodic replacement parts

There are no parts in this machine that require periodic replacement by a service engineer.

(4) Replacement consumables

There are no consumables that require replacement by a service engineer.

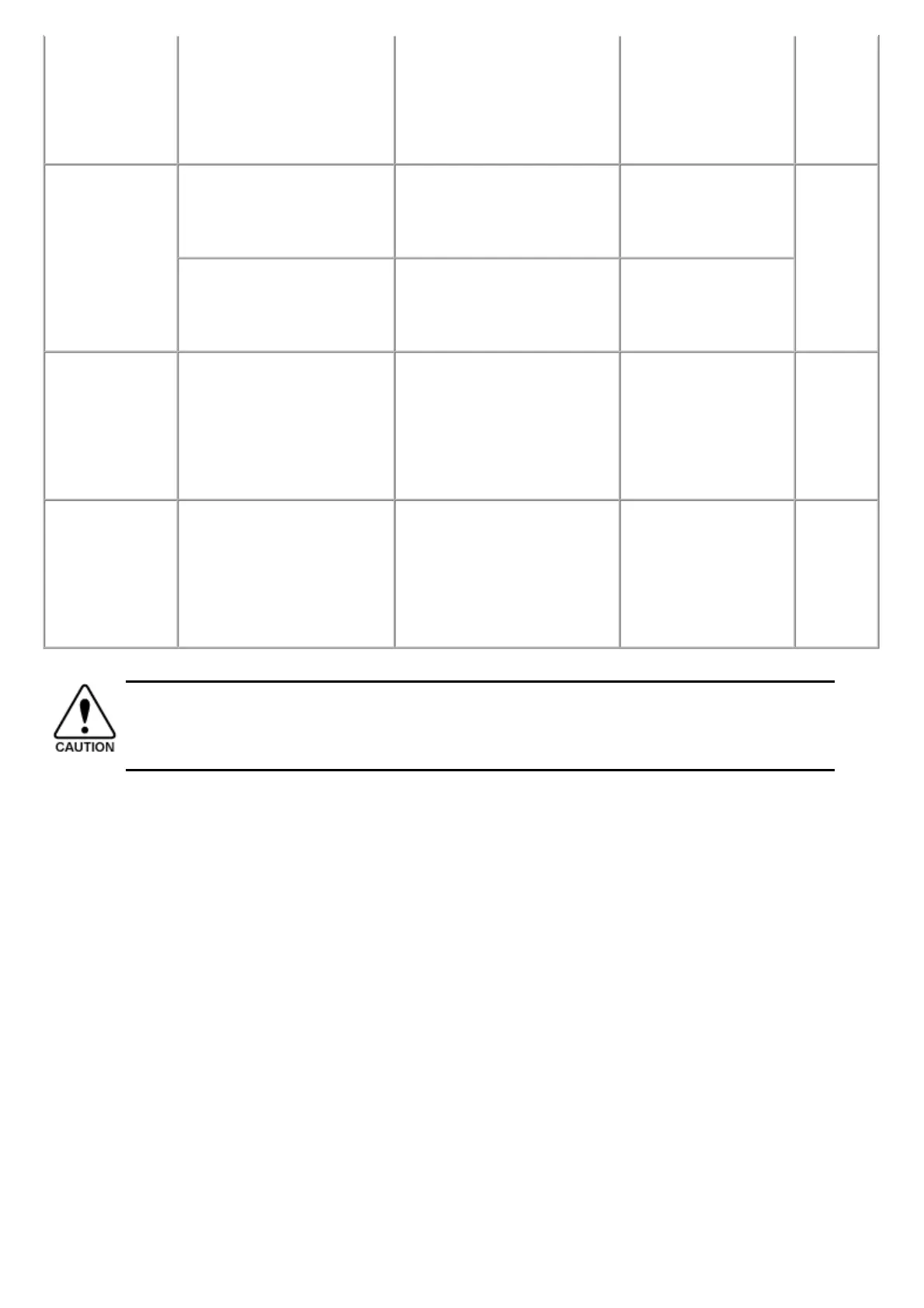

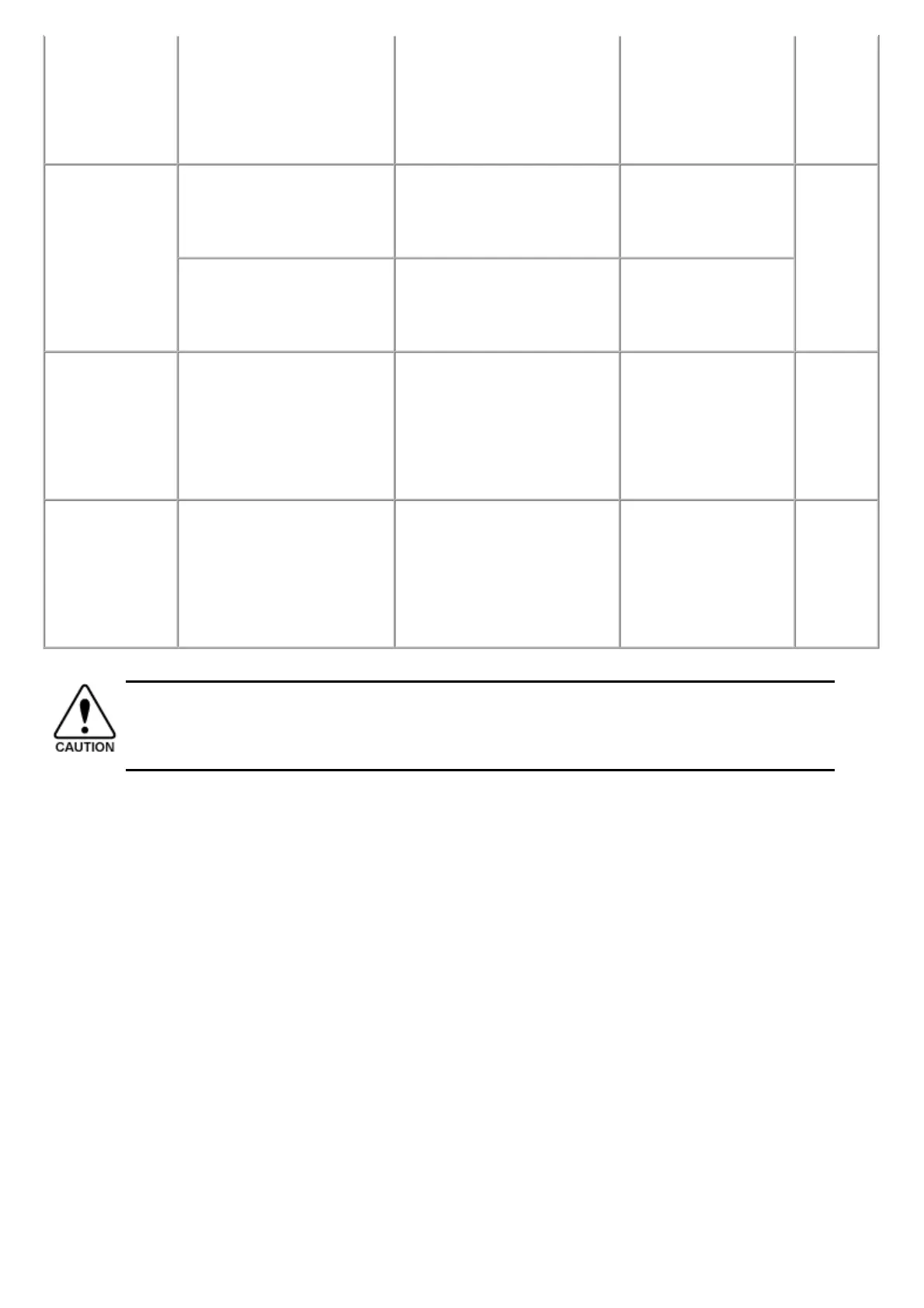

Platen glass

protection sheet

(document

pressure plate

sheet) position

adjustment

- At protection sheet

replacement

- At protection sheet frame

replacement

- At scanner unit replacement

To maintain scanning accuracy,

hold the sheet with the long side

down, then fit its lower right

corner to the platen glass

reference mark (back left).

None. 1 min.

LF / Eject

correction

- At logic board replacement

- At feed roller ass'y

replacement

To correct line feeding (LF roller

diameter).

None.

Perform in the service

mode.

5 min.

(LF

correction

and Eject

correction

is

performed

at the same

time.)

- At logic board replacement

- At platen unit replacement

To correct line feeding (eject

roller diameter).

None.

Perform in the service

mode.

LAN resetting - At logic board replacement To initialize the network setting None.

Perform in the user mode.

- Machine buttons

- Host computer (IJ

Network tool)

- WEB UI (DTV) (Japan

only)

1 min.

LAN setting

information

display

- At confirmation of the network

setting (as needed)

To confirm the network setting None.

Perform in the user mode.

- Machine buttons

- Host computer (IJ

Network tool)

- WEB UI (DTV) (Japan

only)

1 min.

- DO NOT loosen the red screws at both ends of the carriage shaft, securing the print head position, as they

are not re-adjustable.

- The red screws securing the paper feed motor may be loosened only at replacement of the paper feed motor

unit.

Loading...

Loading...