Standard Shelter

Cod. +030221471 – Rel. 2.0 – April 01, 2003

23

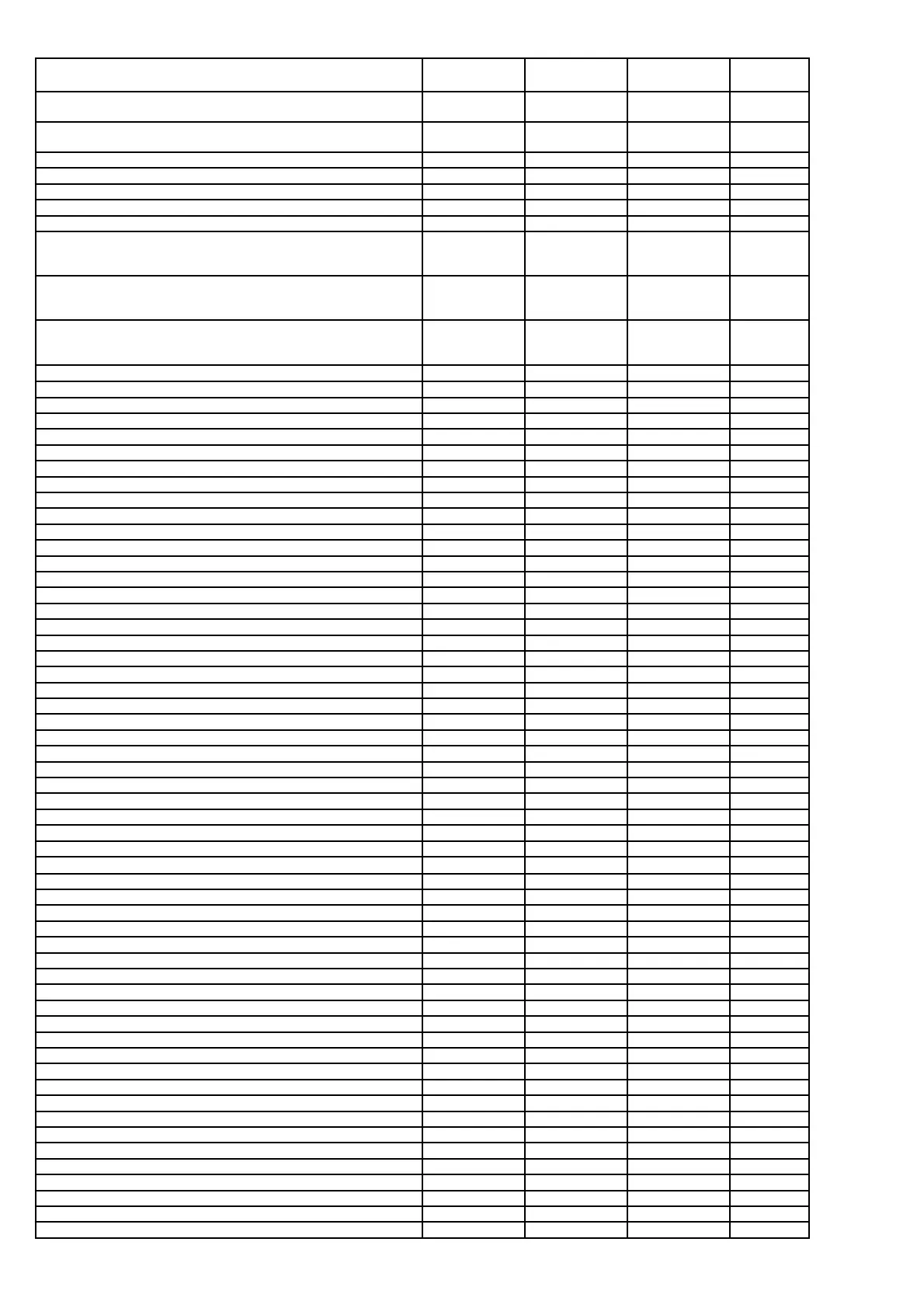

DESCRIPTION OF THE PARAMETER SCREEN DEFAULT

VALUE

RANGE UOM

Type of signal from humidity probe (No pCO1xs) Cc 0-1V 0-1V,0-10V,

current

Minimum and maximum value measured by the humidity probe (No

pCO1xs)

Cc 0.0 / 100.0 0-100.0 %RH

Type of signal from room temperature probe Cd NTC NTC-PT1000

Enable outlet probe Cd No No-Yes

Type of signal from outlet temperature probe Cd NTC NTC-PT1000

Enable outside temperature probe Ce No No-Yes

Type of signal from outside temperature probe Ce NTC NTC-PT1000

pLAN connection class for boards 1 – 3

Cf

Present-no rot.

Present-rot.,

Present-no rot.,

Not present

pLAN connection class for boards 4 – 6 Cg

Not present

Present-rot.,

Present-no rot.,

Not present

pLAN connection class for boards 7 – 8 Ch

Not present

Present-rot.,

Present-no rot.,

Not present

PARAMETERS →

Enable FIFO rotation between compressors G1 No No-Yes

Type of temperature control G1 Proportional Prop.-P+I

Percentage of the proportional band for minimum freecooling opening G2 0.0% 0.0-100.0

Percentage of the proportional band for maximum freecooling opening G2 50.0% 0.0-100.0

Minimum freecooling opening G2 2.0 0.0-10.0 Volt

Minimum and maximum modulating outlet fan speed G3 5.0 / 10.0 0.0-10.0 Volt

Outlet fan speed during dehumidification G3 5.0 0.0-10.0 Volt

Temperature differential to stop dehumidification G4 5.0 0.0-99.9 ºC / ºF

Temperature offset to restart dehumidification G4 4.0 0.0-99.9 ºC / ºF

High pressure alarm set point G5 23.5 -99.9 - 99.9 bar

High pressure alarm differential G5 1.0 -99.9 - 99.9 bar

Condensing (pressure) set point G6 14.0 -99.9 - 99.9 bar

Condensing (pressure) differential G6 2.0 -99.9 - 99.9 bar

Modulating condenser fan Speed-up time G6/G7 2 0-999 seconds

Condensing (temperature) set point G7 55.0 -99.9 - 99.9 ºC / ºF

Condensing (temperature) differential G7 1.0 -99.9 - 99.9 ºC / ºF

Minimum and maximum modulating condenser fan speed G8 0.0 / 10.0 0-10.0 Volt

Enable high pressure alarm Prevent function G9/Ga No No-Yes bar

Prevent function set point (pressure) G9 20.0 -99.9 - 99.9 bar

Prevent function differential (pressure) G9 2.0 -99.9 - 99.9 bar

Prevent function set point (temperature) Ga 70.0 -99.9 - 99.9 ºC / ºF

Prevent function differential (temperature) Ga 1.0 -99.9 - 99.9 ºC / ºF

Number of units set in Standby mode Gb 0 0-1

Automatic rotation interval for units in pLAN network Gb 24 1-240 Hours

Enable cooling/heating Support function for units in pLAN network Gc No No-Yes

Forcing delays for low and high ambient temperature Gc 3 / 3 0-999 minutes

Low ambient temperature differential to force unit in network Gd 8 0-99.9 ºC / ºF

Low ambient temperature offset to force unit in network Gd 4 0-99.9 ºC / ºF

High ambient temperature differential to force unit in network Ge 8 0-99.9 ºC / ºF

High ambient temperature offset to force unit in network Ge 4 0-99.9 ºC / ºF

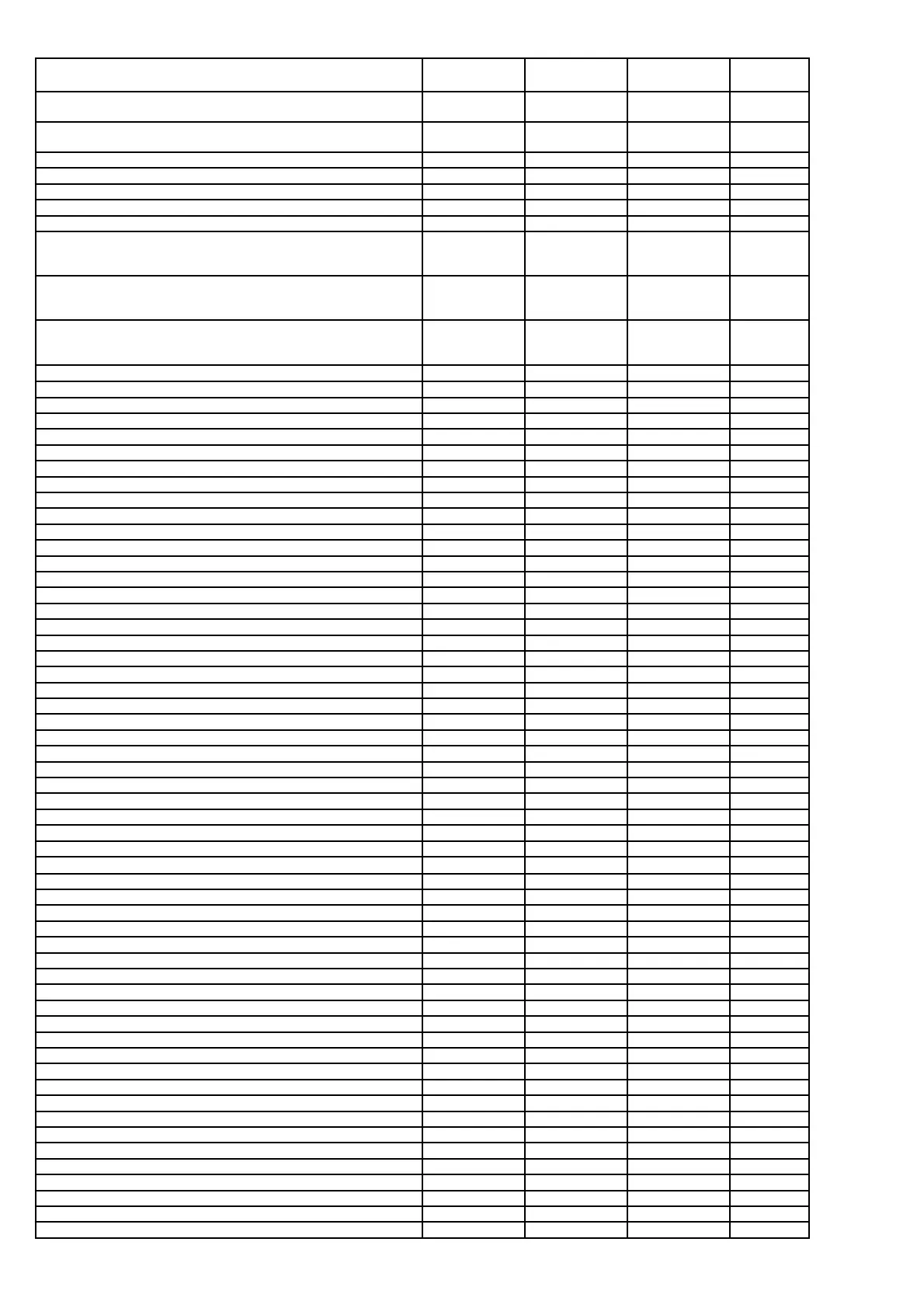

CAREL EXV DRIVERS →

Number of drivers connected F0 0 0-2

Enable backup battery driver 1 F0 No No-Yes

Enable backup battery driver 2 F0 No No-Yes

Type of valve circuit 1 F1 10 (Carel) 0-11 (see 1.5)

Superheating set point circuit 1 F1 6.0 2.0-50.0 ºC

Dead band circuit 1 F1 0 0-9.9 ºC

Type of valve circuit 2 F2 10 (Carel) 0-11 (see 1.5)

Superheating set point circuit 2 F2 6.0 2.0-50.0 ºC

Dead band circuit 2 F2 0 0-9.9 ºC

PID control – proportional gain circuit 1 F3 2.5 0.0-99.9

PID control – integration time circuit 1 F3 25 0-999 seconds

PID control – derivative time circuit 1 F3 5.0 0.0-99.9 seconds

PID control – proportional gain circuit 2 F4 2.5 0.0-99.9

PID control – integration time circuit 2 F4 25 0-999 seconds

PID control – derivative time circuit 2 F4 5.0 0.0-99.9 seconds

Threshold for low superheat protection circuit 1 F5 4.0 -4.0 - 10.0 ºC

Prot. threshold integration time, low superheat circuit 1 F5 10 0-255 seconds

Threshold for low superheat protection circuit 2 F6 4.0 -4.0 - 10.0 ºC

Prot. threshold integration time, low superheat circuit 2 F6 10 0-255 seconds

Percentage ratio between cooling capacity and Driver capacity C 1 F7 60 0-100 %

Percentage ratio between cooling capacity and Driver capacity C 2 F7 60 0-100 %

LOP threshold F8 -40.0 -70.0 - 50.0 ºC

LOP threshold integration time F8 40 0-255 seconds

Loading...

Loading...