Carpigiani K 3 User’s guide

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 44 of 63

Version 5: October 2012

6.3 WASHING AND SANITIZING OF COMPONENT PARTS

step 1

Fill a clean sink with the McD All Purpose Super Concentrate (APSC) and hot water 122-140°F (50-60°C)

(or with hot McD APSC from the KayStar dispenser at the back sink).

step 2

Wash the disassembled parts with the APSC solution and scrub them thoroughly with the brushes

provided with the machine. As you proceed, rinse with hot water. Make sure all lubricant and mix film is

removed from parts.

step 3

Fill another sink with McD Sanitizer prepared in water 70-90°F (21-32°C) [1 packet in 2-1/2 gal. (9-1/2

litres) of water = 100 PPM].

step 4

Place the parts in the sanitizing solution. Leave them there for at least 1 minute.

step 5

Place the components on the milk shake tray to air-dry.

step 6

Place the sundae components on the sundae tray to air-dry.

step 7

Return to the machine with a small amount of McD Sanitizer.

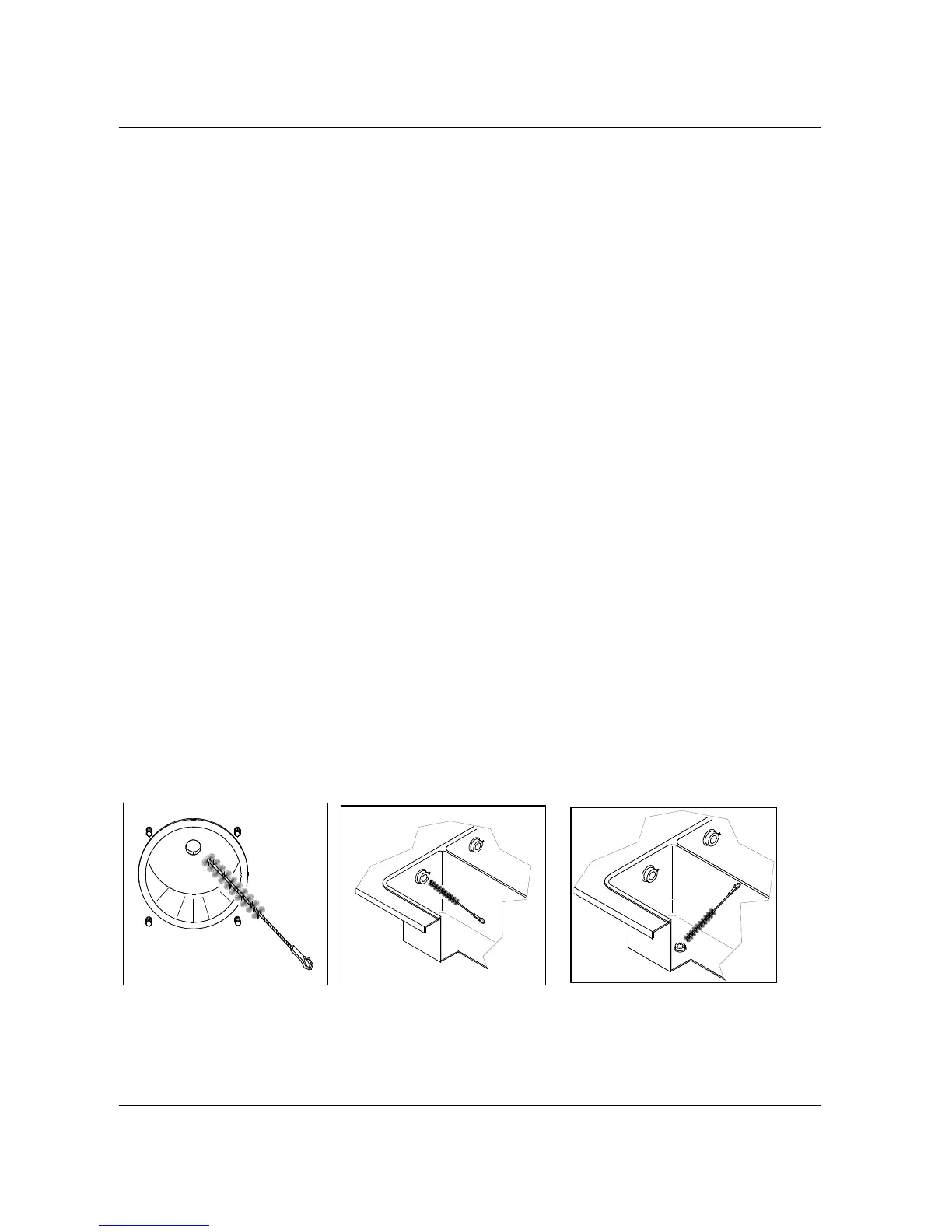

step 8

Dip a brush into the sanitizer and thoroughly brush both freezing cylinders.

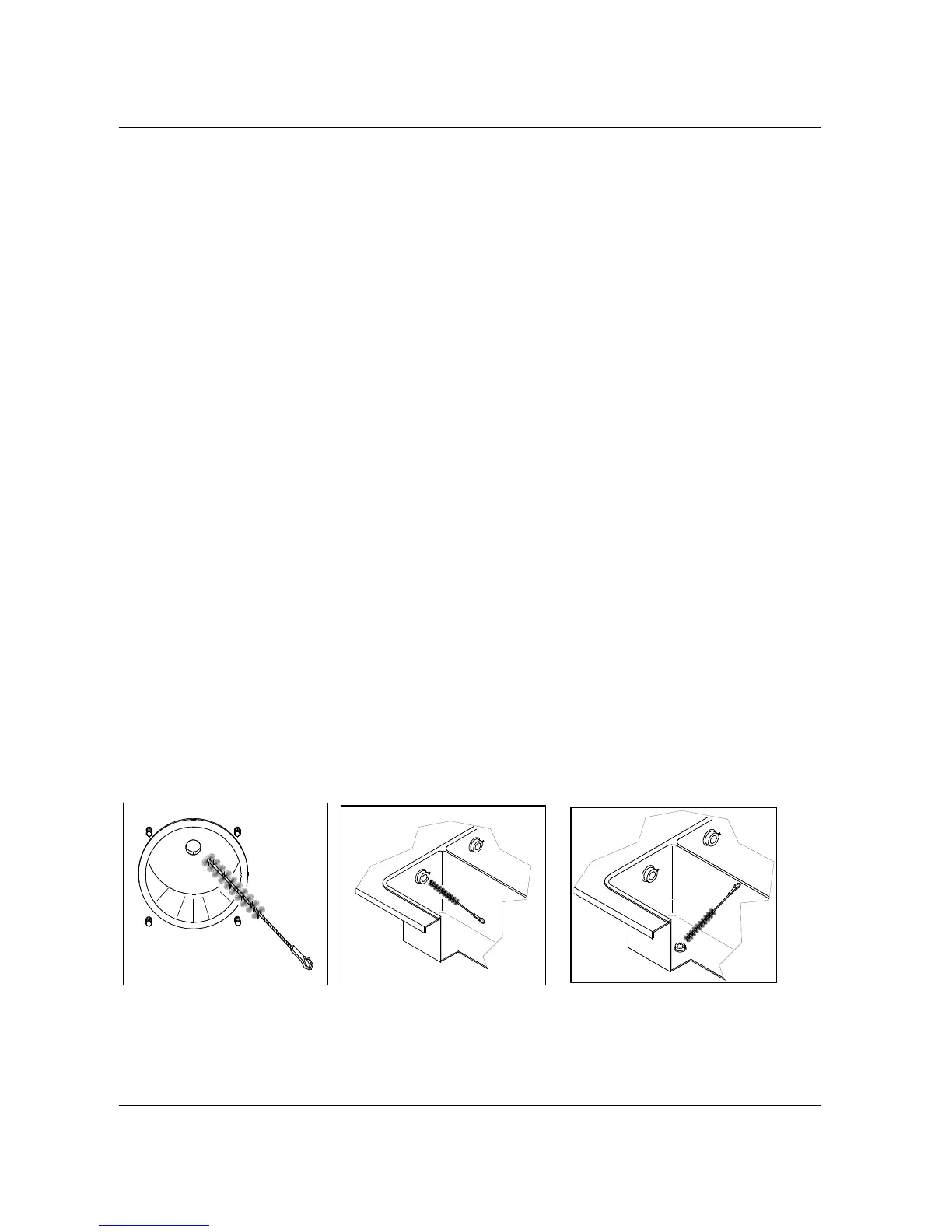

step 9

Dip a brush into the sanitizer and thoroughly brush clean the mix inlet hole and the pump drive hub

openings in the rear of both mix hoppers.

Step 10

Spray the back of cylinder with sanitizer.

Loading...

Loading...