Carpigiani K 3 User’s guide

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 9 of 63

Version 5: October 2012

1. Introduction

1.1 GENERAL INFORMATION

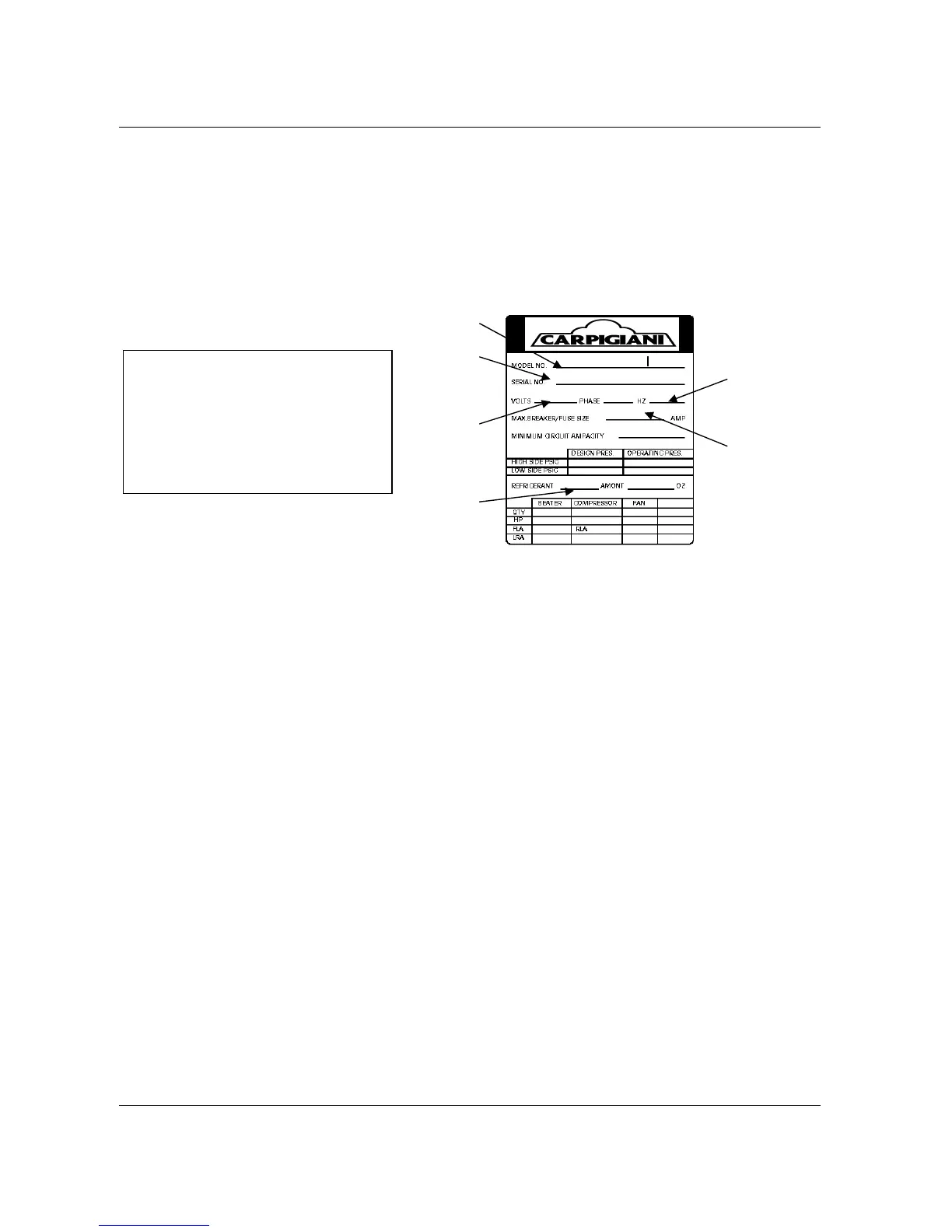

1.1.1 MANUFACTURER'S IDENTIFICATION DATA

The machine has a data plate carrying manufacturer data, machine type and serial number, assigned

when it is manufactured.

1.2 INFORMATION ABOUT THE MACHINE

1.2.1 GENERAL DATA

Electronic, self-heat-treatment, floor machine, for the production and immediate distribution of

milkshake/ice cream having the following main features:

Refrigerated upper tanks;

Cylinder feeding pumps (to control product overrun);

Automatic system to dispense the milkshake with a 4 flavours syrup selection;

Two containers for hot toppings, with pasteurisation temperature control;

Two containers for room temperature toppings;

Automatic pasteurisation system to heat-treatment the product inside the mix tank and inside the

cylinder during pause periods (for instance, during night time);

Electronic consistency control system hard-o-matic.

1.2.2 INTENDED USE

The K 3 machine must only be used for the production of ice cream and milkshake, within the functional

limits listed below:

Voltage: ±10%

Min. ambient temperature: 50°F (10°C)

Max. ambient temperature: 109°F (43°C)

Max relative ambient humidity: 85%

This machine has been designed for its use in closed places not subject to explosion-proof standards;

consequently, it shall be used in places complying with normal atmosphere..

1.2.3 NOISE

The continuous level of acoustic radiation pressure, which has been weighed and called A on working

place, turns to be lower than 70 dB(A), both by air-cooled and water-cooled units.

LEGEND:

A= Serial number

B= Machine type

C= Voltage

D= Fuss/Breaker size

E= Gas type and weight

F= Frequency

A

B

C

E

F

D

Loading...

Loading...