7

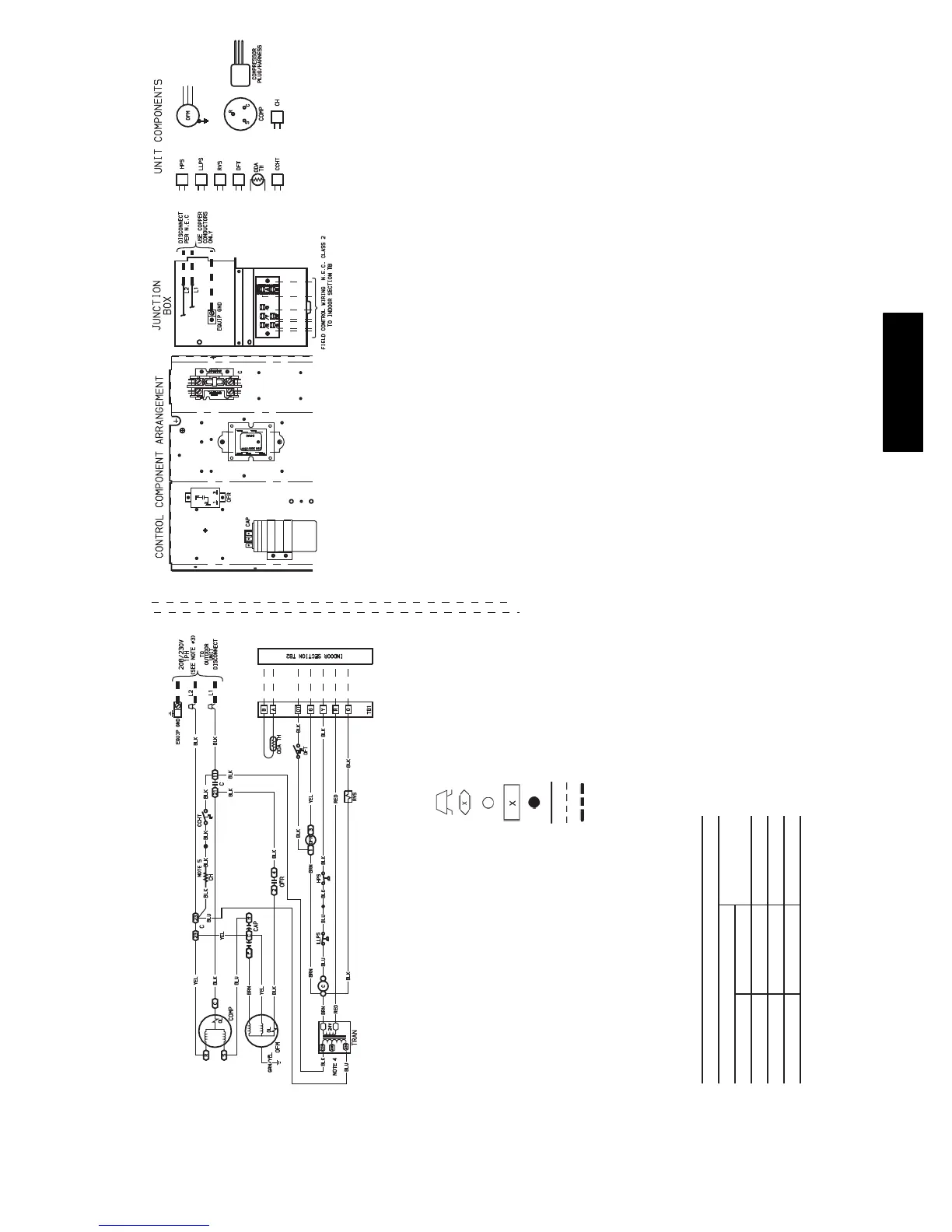

38QRF SCHEMATIC

LEGEND

NOTES:

1. Compressor and fan motors are thermally protected.

2. Wire in accordance with National Electrical Code (NEC) and local codes. Replace any

original wires with 90° C wire or its equivalent.

3. Use minimum 60° C wire for field power wiring.

4. Transformer factory wired for 230 v. For 208 v move blue wire to 208 volt tap.

5. Crankcase heater and thermostat used on selected models only.

NOTE: All thermistors are identical.

THERMISTOR EQUIVALENCE

Temperature

Resistance

FC

95 35 6,500

72 22 11,400

32 0 32,500

C—Contactor, Compressor

CAP — Capacitor

CCHT — Crankcase Heater Thermostat

CH — Crankcase Heater

COMP — Compressor Motor

DFT — Defrost Thermostat

EQUIP — Equipment

GND — Ground

HPS — High-Pressure Switch

LLPS — Liquid Low Pressure Switch

ODA — Outdoor Air Temperature

OFM — Outdoor Fan Motor

OFR — Outdoor Fan Relay

OL — Overload

RVS — Reversing Valve Solenoid

TB — Terminal Board

TH — Thermistor

TRAN — Transformer

Splice (Field)

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Splice

Factory Wiring

Field Control Wiring

Field Power Wiring

38QRF OPERATION SEQUENCE

CALL FOR COOLING:

1. Control voltage from transformer to microprocessor control in indoor unit (24 v).

2. At microprocessor control 24 v is switched to “G,” “O,” and “Y.”

3. 24 v from microprocessor control “G” energizes fan relay at outdoor unit and outdoor-fan motor

runs.

4. 24 v from microprocessor control “O” energizes RVS at outdoor unit through “O” on outdoor unit

terminal board.

5. 24 v from the microprocessor control “Y” energizes the contactor coil in the outdoor unit. The com-

pressor will run.

6. If the HPS, internal protector of the compressor, or LLPS open, the 24 v to the contactor will be

interrupted. The compressor and outdoor fan motor will stop.

CALL FOR HEATING:

1. Control voltage from transformer to microprocessor control in indoor unit (24 v).

2. At microprocessor control 24 v is switched to “G,” “Y,” and “R.”

3. 24 v from microprocessor control “G” energizes fan relay at outdoor unit and outdoor fan motor

runs.

4. 24 v from microprocessor control “Y” energizes the contactor coil and the compressor will run.

5. Demand defrost is controlled by the indoor unit microprocessor control.

6. The indoor unit microprocessor control continuously monitors both outdoor coil temperature and

outdoor ambient temperature, determining the optimum defrost length and interval for existing out-

door conditions.

DEFROST MODE:

1. Microprocessor control switches 24 v to “O” and energizes RVS.

2. Microprocessor control switches 24 v from outdoor fan relay, deenergized relay stops outdoor fan

motor operation.

3. Microprocessor control will terminate defrost when outdoor coil sensor reaches 64.4 F or after

10 minutes of defrost operation. Unit then switches back to normal heating mode.

4. During heating or defrost, if the HPS, internal protector of the compressor, or LLPS open, the 24 v

to the contactor coil will be interrupted, the compressor and outdoor fan motor will stop.

A08238

Fig. 7 -- 38QRF018--060 Typical Wiring Schematic

38QRF

Loading...

Loading...