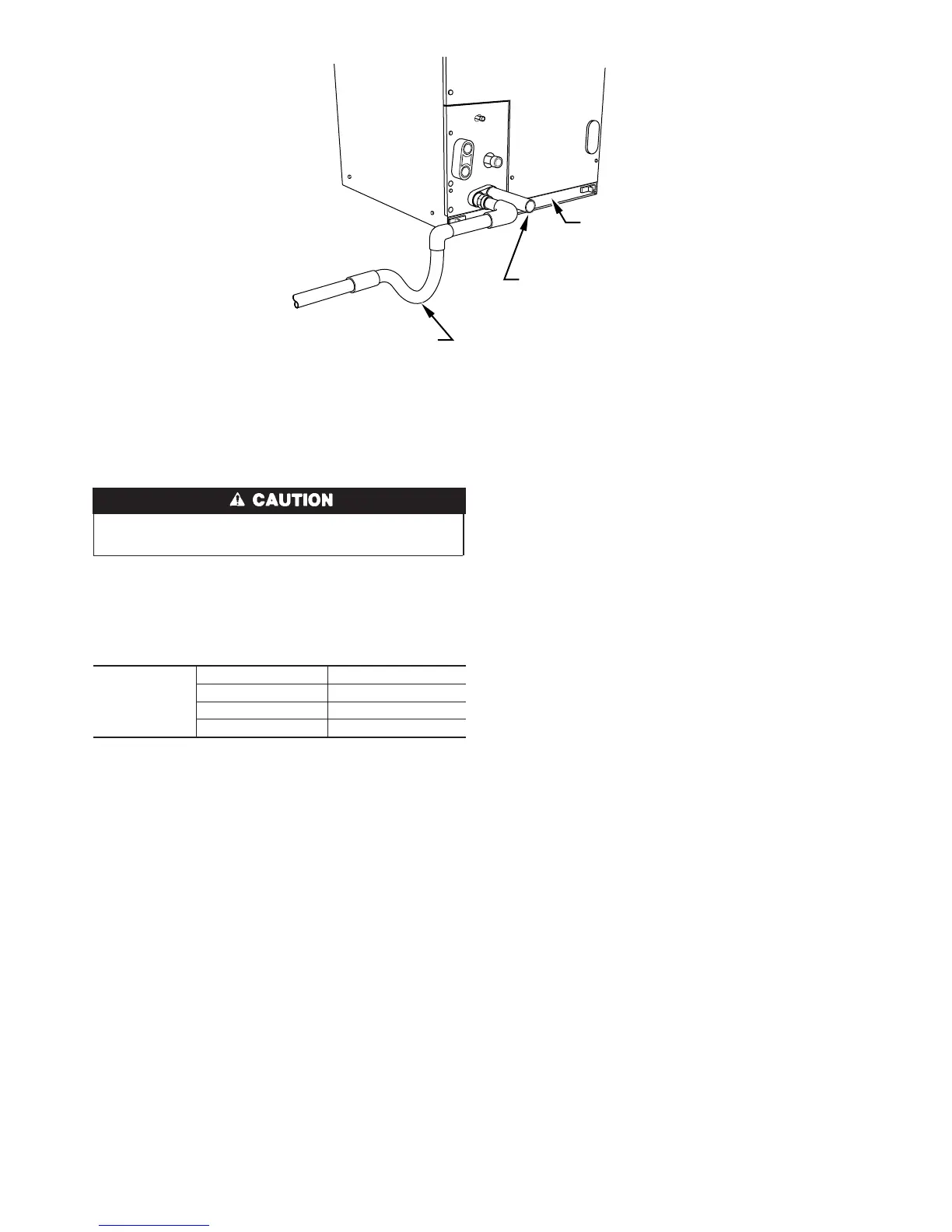

Condensate drain lines should be pitched downward at a minimum

of 1 in. for every 10 ft. of length. Consult local codes for additional

restrictions or precautions.

Never operate unit without a filter or with filter access door

removed. Damage to blower motor or coil can result.

IMPORTANT: Factory authorized filters must be used when

locating the filter inside the unit. (See Table 1.) For those

applications where access to an internal filter is impractical, a

field-supplied filter must be installed in the return duct system.

Step 7—Unit Start-Up

Refer to outdoor unit Installation Instructions for system start-up

instructions and refrigerant charging method details.

Step 8—Easy Select Configuration Taps

(Detail for Quick Reference Guide on back page.)

EASY SELECT taps are used by the installer to configure a

system. ICM2 motor uses the selected taps to modify its operation

to a pre-programmed table of airflows. (See Tables 2 and 3.)

Airflows are based on system size or mode of operation and those

airflows are modified in response to other inputs such as the need

for de-humidification. (See Figs. 16 and 18.)

The 40FKA Fan Coil must be configured to operate properly with

system components with which it is installed. To successfully

configure a basic system (see information printed on circuit board

label located next to select pins), move the 6 select wires to the

pins which match the components used.

AUX HEAT KW/CFM – SELECT HEATER RANGE FOR SIZE

OF ELECTRIC HEATER INSTALLED

Installer must select the auxiliary heat airflow approved for

application with kw size heater installed. If no heater is installed,

this step can be skipped. Each select pin is marked with a range of

heaters for which airflow, also marked, is approved. For increased

comfort select the narrowest kw range matching the heater size, for

example, 0-10 for 10-kw heater. This airflow must be greater than

the minimum CFM for electric heater application with the size

system installed for safe and continuous operation. (See Tables 4

and 5 for airflow delivery and minimum CFM.) Note that airflow

marked is the airflow which will be supplied in emergency heat

mode and heating mode on air conditioners when electric heat is

the primary heating source. In heat pump heating mode when

electric heaters are energized, the ICM2 will run the higher of heat

pump heating airflow and electric heater airflow to ensure safe

heater operation. The factory selection is the largest heater range

approved. (See Fig. 19, A as indicated.)

AC/HP SIZE – SELECT SYSTEM SIZE INSTALLED

The factory setting for air conditioner or heat pump size is the

largest unit meant for application with the model of fan coil

purchased. Installer needs to select air conditioner or heat pump

size to ensure that airflow delivered falls within proper range for

the size unit installed. This applies to all operational modes with

the exception of electric heat modes. (See Fig. 19, B as indicated.)

SYSTEM TYPE – SELECT SYSTEM TYPE INSTALLED AC

OR HP

The type of system must be selected:

1. AC — Air conditioner

2. HP-COMFORT — Provides approximately 315 CFM per ton

for higher normal heating air delivery temperature. Provides

approximately 350 CFM per ton cooling airflow for good

humidity removal.

3. HP-EFF — Provides same airflow for heating and cooling

modes; approximately 350 CFM per ton.

The factory setting is AC. (See Fig. 19, C as indicated.)

AC/HP CFM ADJUST – SELECT MEDIUM, LOW, OR HIGH

AIRFLOW

To provide airflow at rates described above, the AC/HP ADJUST

select is factory set to the nominal (nom) tap. The adjust selections

HI/LO will regulate airflow supplied for all operational modes,

except non-heat pump heating modes. HI provides 15 percent

airflow over nominal unit size selected and LO provides 10 percent

airflow below nominal unit size selected. The adjust selection

options are provided to adjust airflow supplied to meet individual

installation needs for such things as noise, comfort, and humidity

removal. (See Fig. 19, D as indicated.)

Fig. 15—Condensate Drain

A99040

FILTER

ACCESS

PANEL

PRIMARY TRAP REQUIRED

(USE FACTORY KIT OR

FIELD-SUPPLIED TRAP)

SECONDARY DRAIN REQUIRED

(USE FACTORY KIT OR

FIELD-SUPPLIED TRAP)

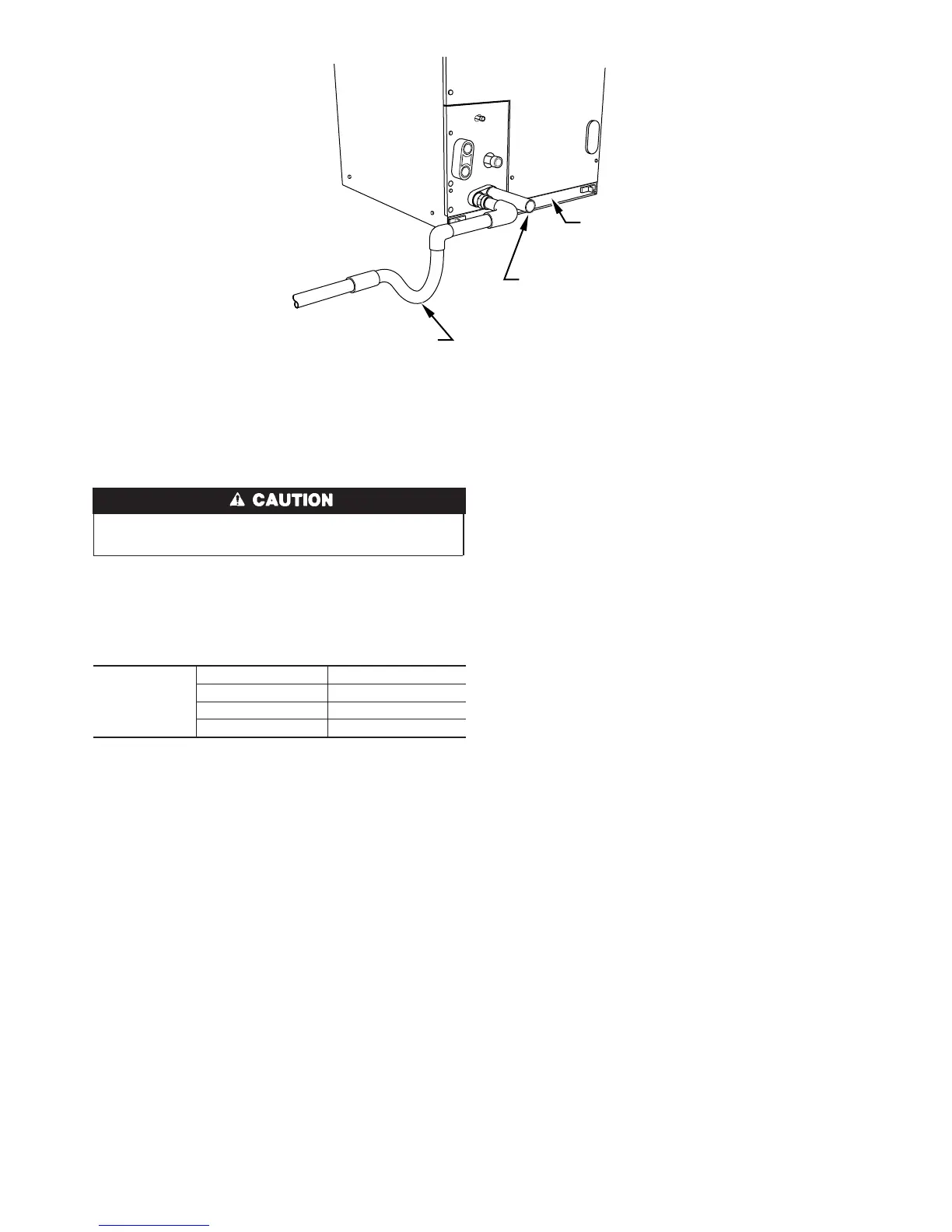

Table 1—Filter Kits

FILTER KIT

(12 PACK)

PART NUMBER SIZE USED WITH

KFAFK0212MED 002,

KFAFK0312LRG 003, 005

KFAFK0412XXL 006

9

Loading...

Loading...